Discover how 3D printing prototypes accelerate product development across automotive, aerospace, healthcare, and consumer industries. Learn about material selection, design tips, and cost efficiency in rapid prototyping.

Introduction

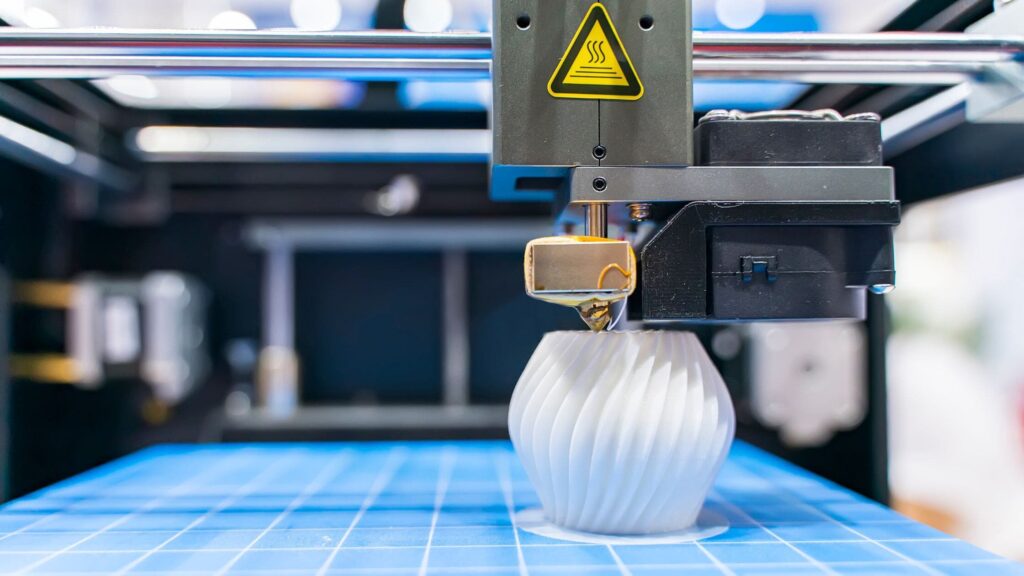

3D printing prototypes, also known as additive manufacturing prototypes, are transforming how companies design and develop products. By enabling rapid prototyping, businesses can significantly reduce time-to-market, lower production costs, and test designs with greater flexibility.

This blog explores the applications of 3D printing prototypes in different industries and highlights the key factors to consider during the 3D printing process to achieve the best results.

Applications of 3D Printing Prototypes

1. Automotive Industry

Automakers use 3D printed prototypes for engine parts, structural elements, and interior designs.

- Case Study: General Motors produces over 30,000 3D printed prototypes annually, reducing development cycles by weeks.

- Benefit: Lightweight designs for improved fuel efficiency and better testing accuracy.

2. Aerospace Sector

The aerospace industry applies 3D printing for lightweight, high-strength parts such as turbine blades and structural supports.

- Additive manufacturing reduces material waste by up to 50% compared to traditional machining.

- Prototypes can be tested under real-world conditions before full-scale production.

3. Healthcare and Medical Devices

In healthcare, 3D printed medical prototypes include prosthetics, implants, and surgical guides.

- Customized patient-specific implants improve recovery outcomes.

- Medical device companies reduce prototype development time from months to weeks.

4. Consumer Products and Electronics

For consumer electronics, 3D printing is widely used to test ergonomic designs, housings, and circuit enclosures.

- Faster testing cycles shorten product launch timelines.

- Enables customization for niche markets.

5. Fashion and Jewelry

In fashion, 3D printed prototypes are used to create intricate jewelry, accessories, and footwear models.

- Supports rapid iteration in design.

- Offers unique customization opportunities.

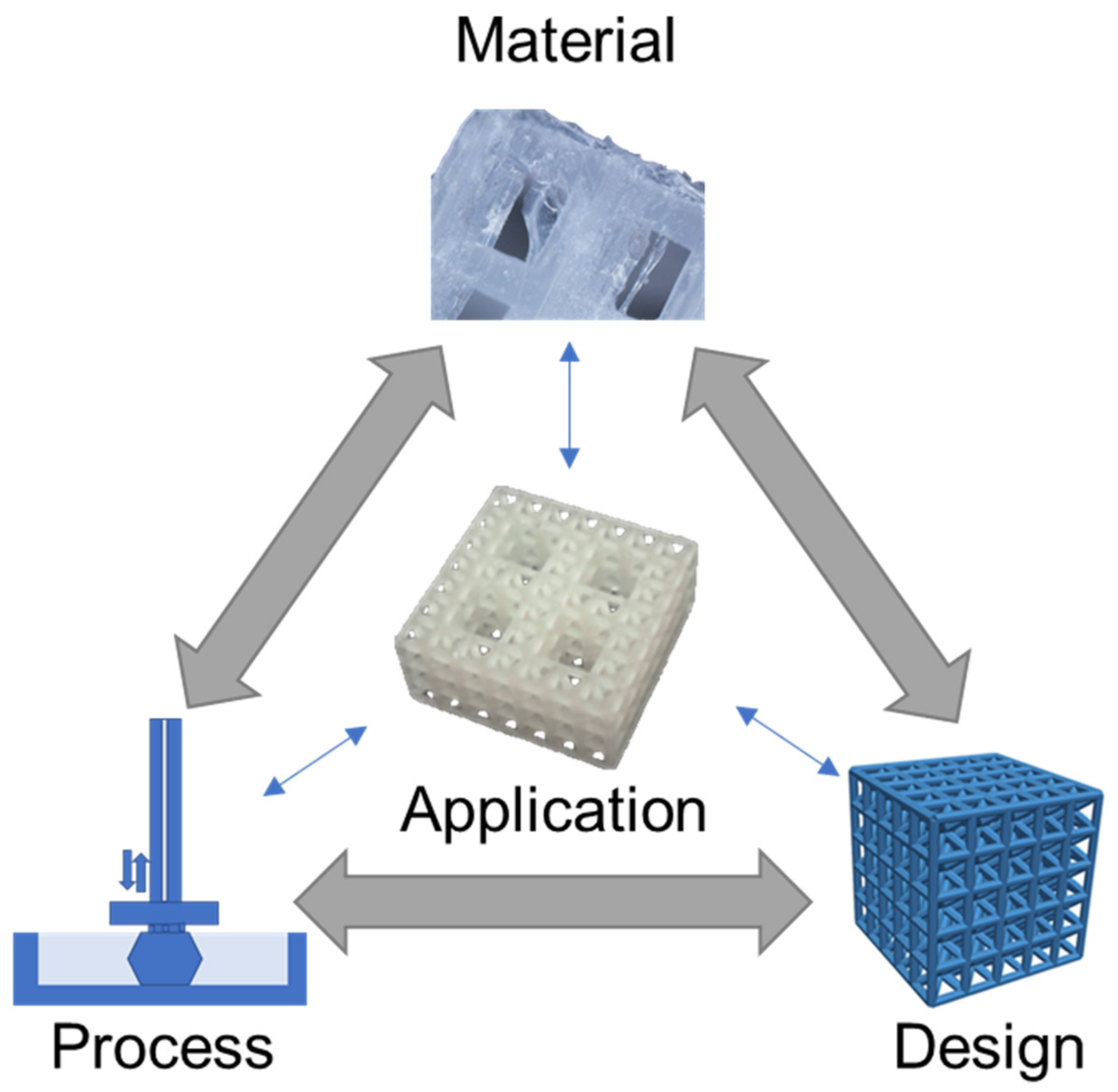

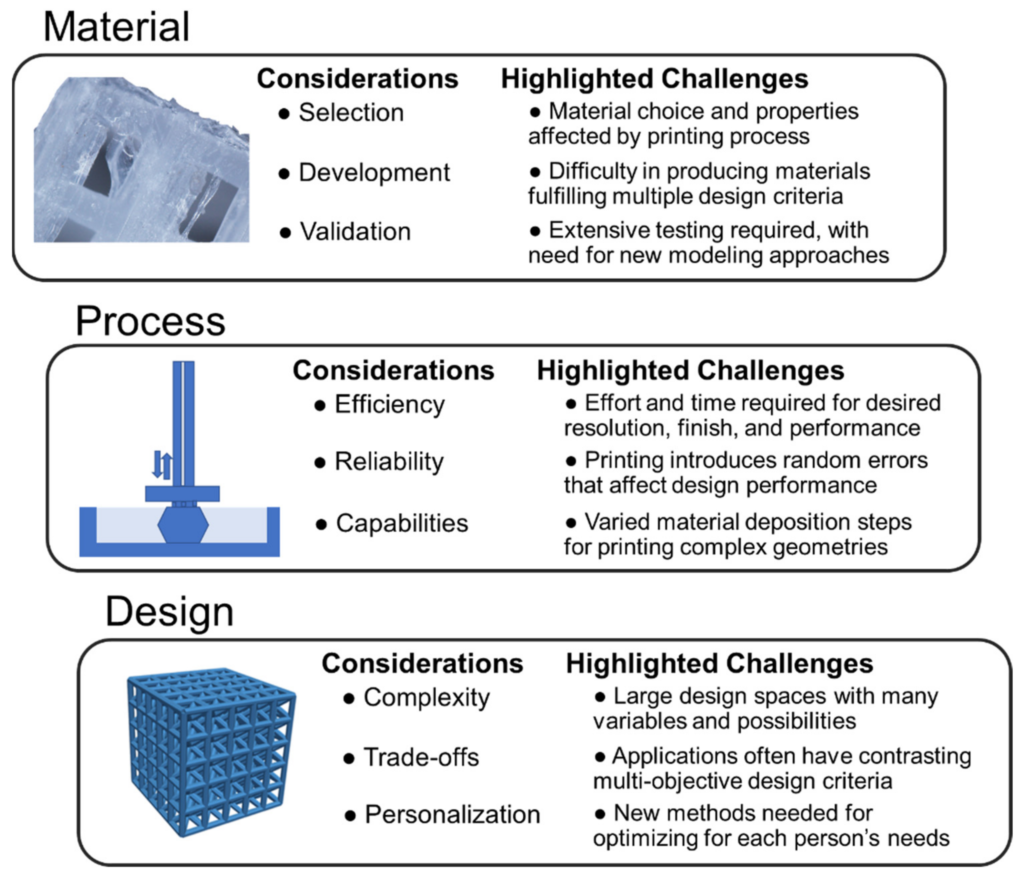

Key Considerations in 3D Printing Prototypes

1. Material Selection

Selecting the right 3D printing materials—such as PLA, ABS, resin, or TPU—is critical. Each has unique properties:

- PLA: Affordable, easy to print, ideal for visual prototypes.

- ABS: Stronger, suitable for functional testing.

- Resin: High detail, smooth finish, often used in medical/dental prototypes.

- TPU: Flexible, ideal for wearable products.

2. Design for Manufacturability

Effective 3D prototype design must consider:

- Avoiding steep overhangs.

- Adding support structures.

- Correct layer orientation for strength and precision.

3. Tolerances and Fit

Different 3D printing technologies (SLA, SLS, FDM) have varying tolerances.

- SLA: High precision, ±0.1 mm.

- FDM: ±0.2–0.5 mm.

- SLS: Durable, but rougher surface.

Designers must adjust clearances to ensure assembled parts fit correctly.

4. Post-Processing

Many prototypes require post-processing:

- Sanding or polishing for surface finish.

- UV curing for resin parts.

- Painting or coating for aesthetics and durability.

5. Cost and Time Efficiency

3D printing eliminates tooling costs, but businesses should evaluate:

- Material cost per prototype.

- Print duration (complex parts may take 10+ hours).

- Post-processing labor.

Studies show 3D printing reduces prototyping costs by 30–70% compared to traditional methods.

Conclusion

3D printing prototypes have become a critical tool for industries from automotive and aerospace to healthcare and consumer electronics. By carefully considering materials, design constraints, tolerances, post-processing, and cost efficiency, companies can leverage rapid prototyping to shorten development cycles and improve product performance.

At Ze-tech Mold, we provide end-to-end 3D printing prototype solutions, from small-batch prototyping to large-volume production. Our expertise ensures that every prototype meets your functional and aesthetic requirements.

👉 Contact us today to discuss how we can help accelerate your product development.