ZE-TECH 3D printing prototype service

3D Printing Prototyping

At ZE-TECH, we provide a custom 3D printing prototype service for low-volume production.

3D printing prototyping, also known as rapid prototyping or 3D rapid prototyping, has revolutionized the way products are designed and developed. By leveraging the power of additive manufacturing technology, 3D printing offers an efficient and cost-effective method for creating physical prototypes directly from digital designs.

Which service would you like?

Here are three 3D printing prototype services for you to choose from.

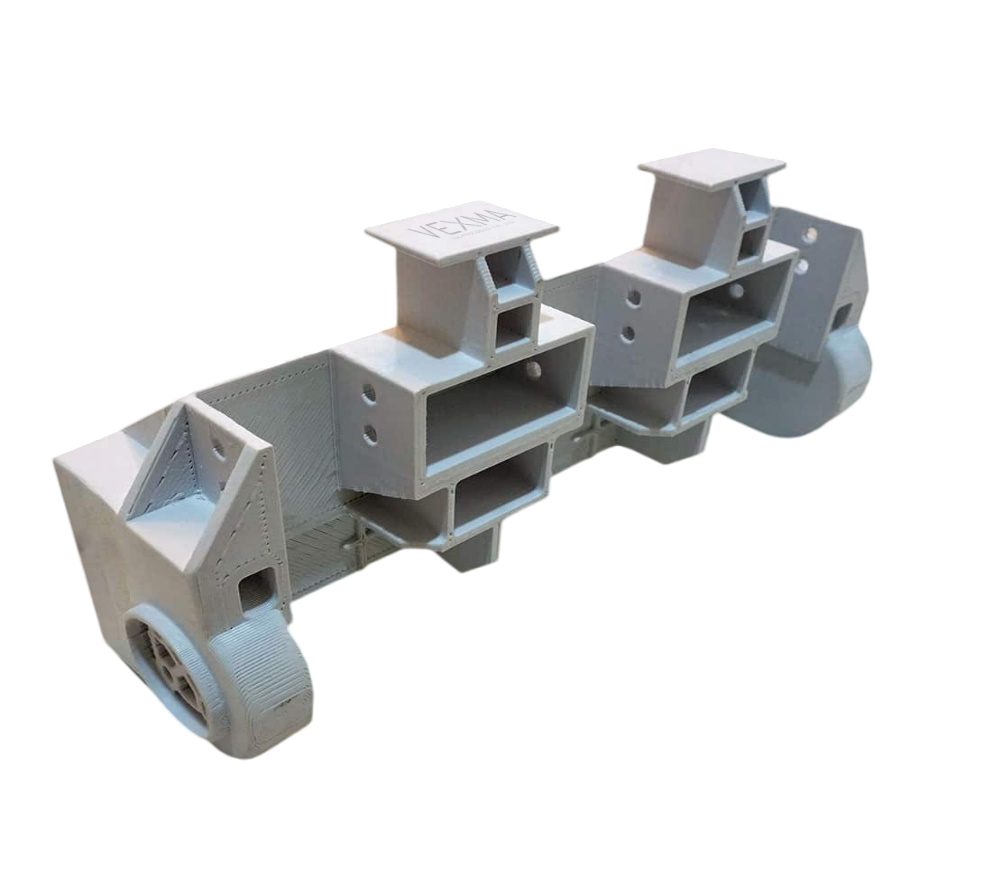

Except for plastic, metal is also a popular material for producing printing prototypes with much more complicated structure. The common metals for printing are aluminum, stainless steel, etc.

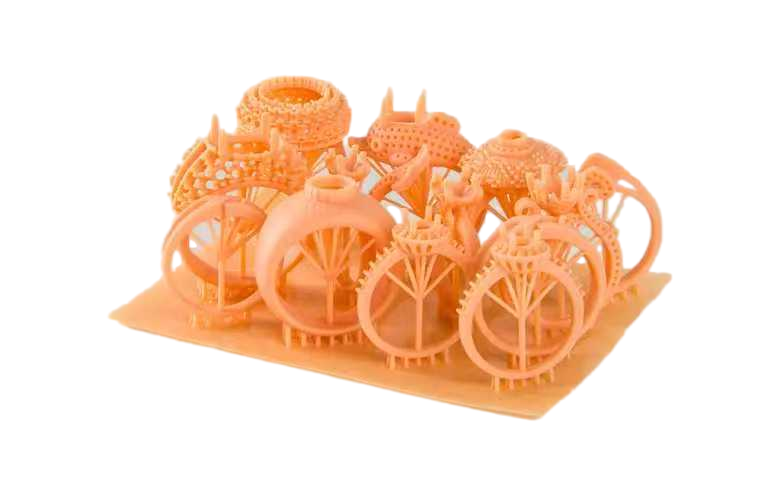

SLA rapid prototyping is one of the common printing techniques for creating quality prototypes. Its mostly used material is resin. At Ruitai, you can also choose painting to add more aesthetic for 3D printing parts.

Another printing technique is SLS rapid prototyping, which prints the parts by powder. It can create metal and plastic prototypes without support structures.

what you want to know?

- Production : High-efficient manufacturing and fit for Low-volume prototypes

- Advantages : Flexible,Highly efficient,Economic,No material was te

- Checking Tools : CMM checking equipment,Height gauge,Tap gauge,Calipers,etc

- Resolution : ±0.05mm

- Build Envelope : 450*450*300mm

- Surface Treatment : Blasting Spray painting Media tumbling,Dyeing,etc

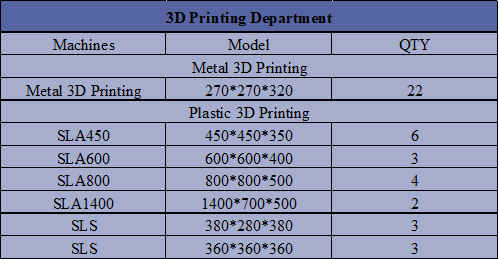

Core Technologies

PolyJet Technology

Jets photopolymer materials for multi-material prototypes with varied elasticity/colors.

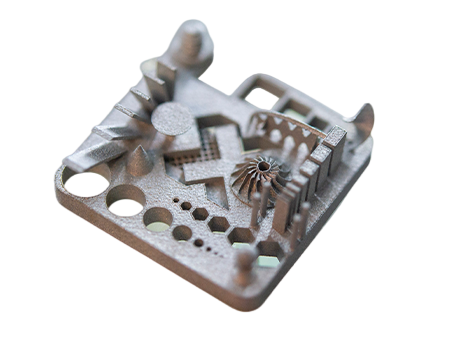

Metal 3D Printing

Direct Metal Laser Sintering (DMLS) or Binder Jetting creates aerospace-grade metal components.

Selective Laser Sintering (SLS)

Fuses polymer powders (nylon, TPU) with lasers, producing durable, functional parts.

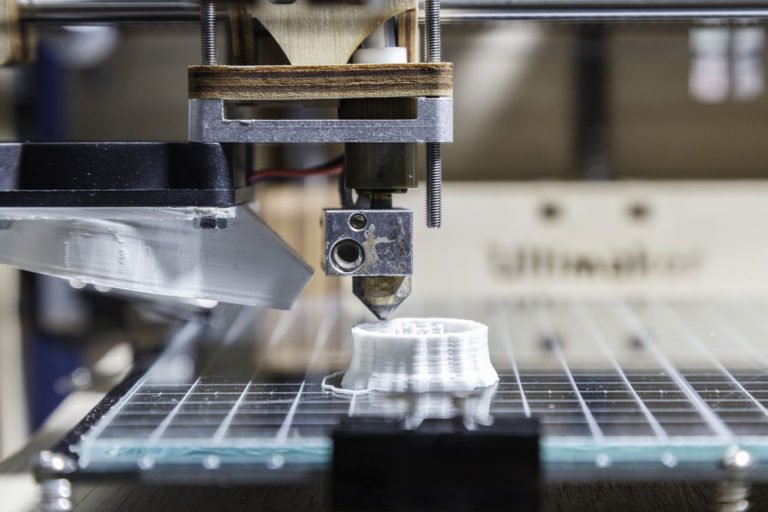

Fused Deposition Modeling (FDM)

Extrudes thermoplastic filaments (ABS, PLA, PETG) for cost-effective concept models.

Stereolithography (SLA)

Uses UV lasers to cure liquid photopolymers, delivering high-resolution surface finishes.

Key Advantages

✅ Design Freedom: Manufacture hollow structures, internal channels, and organic shapes impossible with CNC.

✅ Speed: Produce prototypes in hours vs. weeks (traditional methods).

✅ Cost Efficiency: Eliminate tooling costs; ideal for low-volume batches.

✅ Iterative Agility: Facilitate rapid design modifications based on real-time testing.

3D printing prototype cases

ZE-TECH 3D Printing Prototype Service Frequently Asked Questions

We know that you may have some questions about 3D Printing Prototype services. We have compiled the answers to the following common 3D Printing Prototype project questions, hoping to help you.

Why Should You Use 3D Printing Prototype?

The explanation behind utilizing a 3D printer is that you can make a 3D model of your Computer-Aided Design without the requirement for tooling or expert programming abilities. You can browse an assortment of materials, and various goals to suit your application.

3D Printing Prototype machines are enhanced for speed, relative minimal effort, and usability which makes them appropriate for picturing plans during the calculated phases of your plan when properties, for example, mechanical strength are less significant.

How Does The Process Work?

3D Printing Prototype works by changing over a 3D computerized plan into dainty cross areas that are controlled by the 3D printer programming. This data is then shipped off the machine where it begins to store material layer by layer, one over the other, hence making a 3-dimensional article. This interaction is designated “Added substance Layer Manufacturing”.

How is 3D Printing Prototype exploit in Product Evolution?

This 3D Rapid Prototype can be utilized at pretty much every phase of the item advancement cycle. High exactness, dependable quality models can help your business at each progression. Represent your items to likely financial backers, accomplices, and clients with a full tone, full-size models on the right surfaces, and completes to completely clarify how they will look and feel.

Demonstrate your plan works with a full-size, useful, working demonstrator. Abbreviate your chance to showcase and keep up short lead times. Assembling intriguing articles by joining tones, transparencies, and hardness novelty, and even tweak each item you produce to your customer.

What Is The Contrast Between An Example And A Model on 3D Printing Prototype?

Some may utilize these terms conversely. But a model is a verification of how your thought works. An example is a thing that an assembling gives you before creation. It guarantees what the last creation item will resemble out of the production line machines.

Does Stereolithography (SLA) Helps in 3D Printing?

It is a type of 3D Printing Prototype in which the parts are manufactured layer by layer using different photochemical techniques.

Stereolithography is a process in which a bright beam centering on a photopolymer gum. Working of the 3D Printers and shading up the layers of models is done in this process.

Then, these shaded layers are brought into machine again and the machine starts to print another layer. After the communication is done, the parts ought to be cleaned from every one of the wet pitches. Similarly, the cutting off of solid developments for overhanging parts is fundamental.

Is Computerized Light Handling a type of 3D Printing Prototype?

Additionally to stereolithography (SLA), computerized light handling is also a 3D Printing Prototype technique that uses a photopolymer pitch that sets under a light source.

The Chief Variance and DLP lasers fix the entire layer of material at the exact same time, while twisted surfaces may have a more unsavory surface and quality appeared differently in relation to SLA.