In today’s fast-paced manufacturing landscape, 3D printing (additive manufacturing) has evolved from a rapid prototyping tool to a viable solution for functional parts, tooling, and even end-use production.

However, the performance, durability, and cost-effectiveness of any 3D printed part depend heavily on one critical factor: material selection.

At Ze-tech Mold, we support customers in choosing the optimal 3D printing material—whether for rapid prototyping, small-batch runs, or large-scale production—ensuring parts meet both engineering and business requirements.

Why Material Selection Matters in 3D Printing

Choosing the right material is not only about mechanical properties—it also impacts:

- Accuracy & Tolerance: Some materials provide tighter dimensional stability.

- Surface Finish & Aesthetics: SLA resins, for example, offer smooth finishes ideal for medical or design applications.

- Functional Performance: High-performance thermoplastics like PEEK can withstand demanding industrial conditions.

- Cost Efficiency: Using engineering-grade materials where necessary, and affordable plastics where possible, balances performance with cost.

Common 3D Printing Material Categories

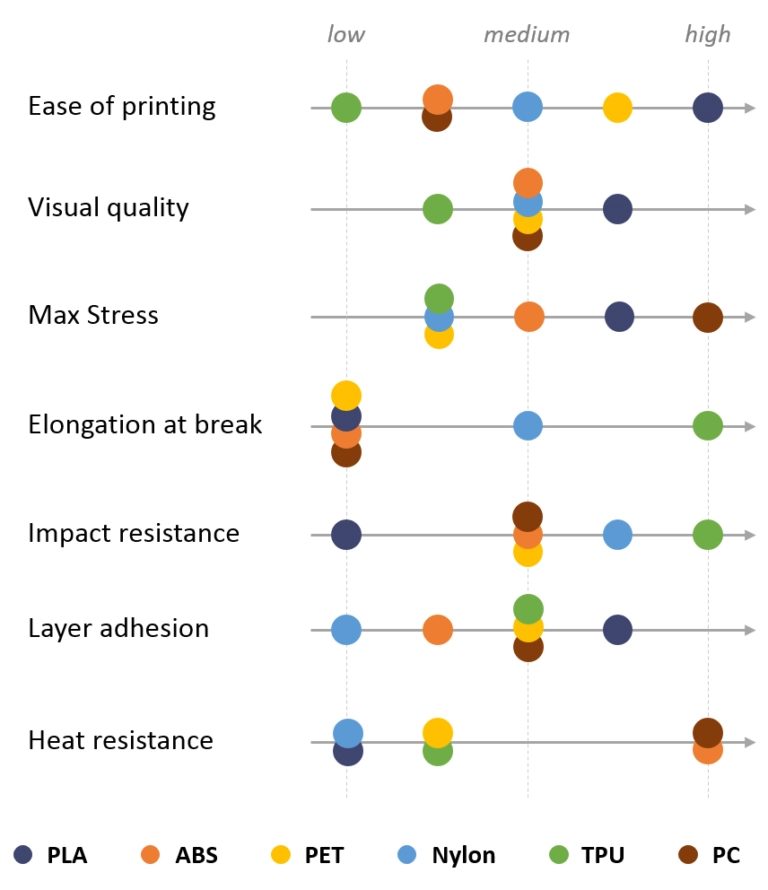

To help you make an informed decision, here’s a professional comparison of the most commonly used 3D printing materials:

| Material Type | Examples | Key Properties | Common Applications | Advantages | Limitations |

|---|---|---|---|---|---|

| Plastics (FDM, SLS) | PLA, ABS, Nylon, PEEK | Lightweight, flexible to strong, moderate heat resistance | Prototypes, consumer goods, automotive brackets | Low cost, versatile, easy to process | Lower strength than metals, may deform under heat |

| Resins (SLA, DLP) | Standard, Tough, Biocompatible | High precision, smooth surface finish, brittle to tough | Dental models, medical guides, design prototypes | Excellent detail, biocompatible options available | Brittle in some cases, limited size |

| Metals (DMLS, SLM, Binder Jetting) | Aluminum, Stainless Steel, Titanium, Inconel | High strength, durability, heat and corrosion resistance | Aerospace, medical implants, industrial tooling | Superior mechanical properties, end-use ready | Higher cost, requires post-processing |

| Composites (FDM, SLS) | Carbon Fiber Nylon, Glass-Filled Nylon | High stiffness, lightweight, good dimensional stability | Aerospace, sporting goods, industrial fixtures | Excellent strength-to-weight ratio | Limited material availability, anisotropy issues |

Key Considerations for Material Selection

When selecting the right 3D printing material for your application, keep the following factors in mind:

- Mechanical Performance – Does the part need high strength, impact resistance, or flexibility?

- Thermal & Chemical Resistance – Will the part be exposed to heat, chemicals, or outdoor environments?

- Surface Finish Requirements – Is appearance and fine detail more important than toughness?

- Cost & Scalability – Does the budget allow for high-performance materials, or is a prototype-grade material sufficient?

- Regulatory Needs – For medical, food-grade, or aerospace applications, certified materials may be necessary.

How Ze-tech Mold Supports Material Selection

At Ze-tech Mold, we provide a wide range of 3D printing prototype services backed by engineering expertise:

- Material Consulting – We help identify the most suitable material based on performance, cost, and production scale.

- Multi-Process Capabilities – From FDM, SLA, SLS, to metal 3D printing, we offer the flexibility to match application requirements.

- Prototype to Production – Whether you need a single prototype or small- to large-batch production, we provide end-to-end solutions.

- Surface Treatments & Secondary Processing – For improved aesthetics and functionality, we offer painting, polishing, and coating services.

By combining technical expertise with advanced manufacturing capabilities, we ensure our clients receive high-quality, application-driven solutions.

Conclusion

Selecting the right 3D printing material is the foundation of successful prototyping and production. From plastics to composites and metals, each category brings unique advantages and trade-offs. A clear understanding of mechanical properties, cost factors, and end-use requirements is essential.

With Ze-tech Mold’s expertise in CNC machining, 3D printing, sheet metal fabrication, and injection molding, we not only deliver high-precision prototypes but also help you make the best material decisions for your projects.

📩 Contact Ze-tech Mold today to discuss your 3D printing needs and find the perfect material for your application.