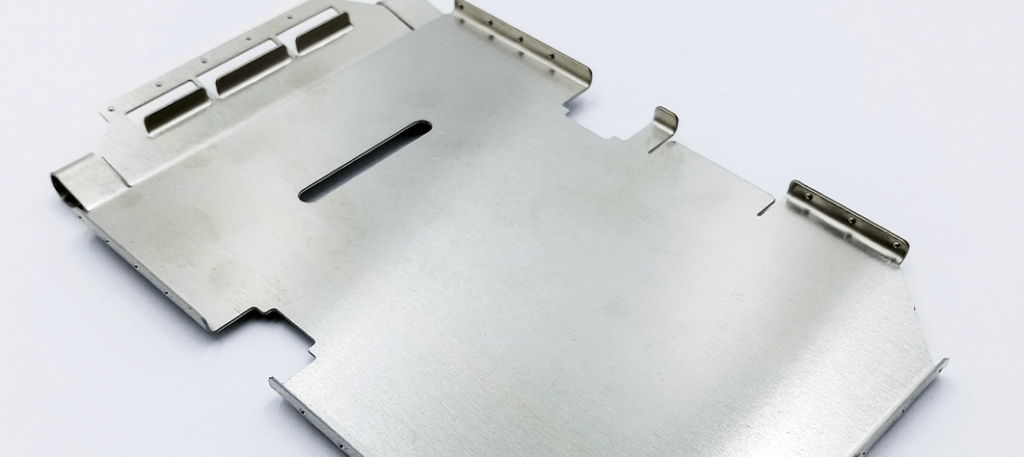

Sheet metal fabrication is a versatile and widely used manufacturing process that supports industries ranging from automotive and aerospace to medical devices and consumer electronics. However, like any complex production method, sheet metal fabrication comes with its own set of challenges. Understanding these potential issues—and knowing how to avoid them—can significantly improve product quality, reduce costs, and optimize lead times.

At Ze-tech Mold, we combine advanced equipment, precision engineering, and rigorous quality control to minimize fabrication risks and ensure reliable outcomes for both prototypes and large-scale production.

1. Material Deformation and Warping

Problem

During bending, stamping, or welding, sheet metal can deform, warp, or twist due to residual stress, uneven heating, or improper tooling.

Causes

- Excessive force applied during bending

- Incorrect bend radius or tooling selection

- High heat input during welding without proper cooling

Avoidance

- Select appropriate tooling and maintain recommended bend radius (typically ≥ 1x material thickness)

- Use stress-relieving techniques such as annealing before processing

- Apply controlled welding methods (e.g., stitch welding, TIG welding) to reduce heat distortion

2. Inaccurate Tolerances and Dimensional Errors

Problem

Maintaining tight tolerances is a major challenge in sheet metal fabrication, particularly for components requiring assembly with other precision parts.

Causes

- Incorrect CAD/CAM design parameters

- Tool wear in punching or laser cutting

- Thermal expansion during cutting or welding

Avoidance

- Use CNC laser cutting or waterjet cutting for high accuracy

- Regularly calibrate and maintain machines

- Compensate for thermal effects during design and production

- Implement in-process inspection and CMM measurement for critical parts

3. Surface Defects (Scratches, Burrs, and Oxidation)

Problem

Surface defects compromise both functionality and aesthetics, especially for visible consumer products or medical devices.

Causes

- Improper material handling or stacking

- Dull cutting tools creating burrs

- Inadequate protective coatings during storage

Avoidance

- Use protective films on sheet surfaces during transport and processing

- Apply deburring and surface treatments (polishing, sandblasting, anodizing, powder coating)

- Store materials in a controlled, dry environment to prevent oxidation

4. Welding and Joint Failures

Problem

Improper welding can lead to weak joints, cracks, or porosity, reducing the mechanical strength of assemblies.

Causes

- Incorrect welding parameters (voltage, current, shielding gas)

- Contamination on surfaces before welding

- Poor joint design for load-bearing parts

Avoidance

- Clean surfaces thoroughly before welding

- Use proper fixturing to maintain alignment

- Optimize joint design (lap joints, fillet welds, gussets for reinforcement)

- Conduct non-destructive testing (NDT) such as ultrasonic or X-ray inspection for critical parts

5. High Production Costs and Inefficiency

Problem

Inefficient processes or poor planning can increase costs, waste materials, and prolong lead times.

Causes

- Overcomplicated designs requiring multiple setups

- Excessive material waste during cutting

- Poor communication between design and manufacturing teams

Avoidance

- Apply Design for Manufacturability (DFM) principles early in product design

- Optimize nesting layouts to reduce scrap during laser cutting

- Collaborate with experienced fabrication partners like Ze-tech Mold for design reviews and cost-saving solutions

6. Assembly and Fitment Issues

Problem

Components may not fit together properly during final assembly, leading to rework or scrapping.

Causes

- Accumulated tolerance errors in multiple parts

- Lack of consideration for fastening methods (rivets, screws, welding)

- Poor alignment of holes and slots

Avoidance

- Use GD&T (Geometric Dimensioning and Tolerancing) in design to define precise requirements

- Incorporate locating features to ensure repeatable assembly

- Test prototypes before full-scale production

Conclusion

While sheet metal fabrication offers unmatched versatility and cost-effectiveness, it also presents challenges such as deformation, tolerance issues, surface defects, and assembly mismatches. By applying best practices in design, process control, and quality assurance, these problems can be minimized or eliminated.

At Ze-tech Mold, we deliver end-to-end solutions in sheet metal fabrication, supported by CNC machining, welding, surface treatments, and assembly services. Whether you need a prototype, small batch, or mass production, our engineering team ensures high-quality results with optimized efficiency.

📩 Contact Ze-tech Mold today to discuss your sheet metal fabrication project and discover how we can help you overcome manufacturing challenges.