Rapid prototyping (RP) is revolutionizing the way products are developed. For product managers, designers, and engineers, mastering rapid prototyping is essential to stay ahead in a competitive market. This article will explain what rapid prototyping is, explore its six key advantages, discuss potential drawbacks, and provide best practices to achieve optimal results.

What is Rapid Prototyping?

Rapid prototyping is the process of quickly creating a prototype to validate design concepts before full-scale production. High-fidelity prototypes often replicate the final product’s design, functionality, and usability, enabling early testing and feedback.

Purpose of rapid prototyping:

- Test ideas early in development

- Reduce costs and material waste

- Identify and correct design flaws before production

Common Rapid Prototyping Techniques:

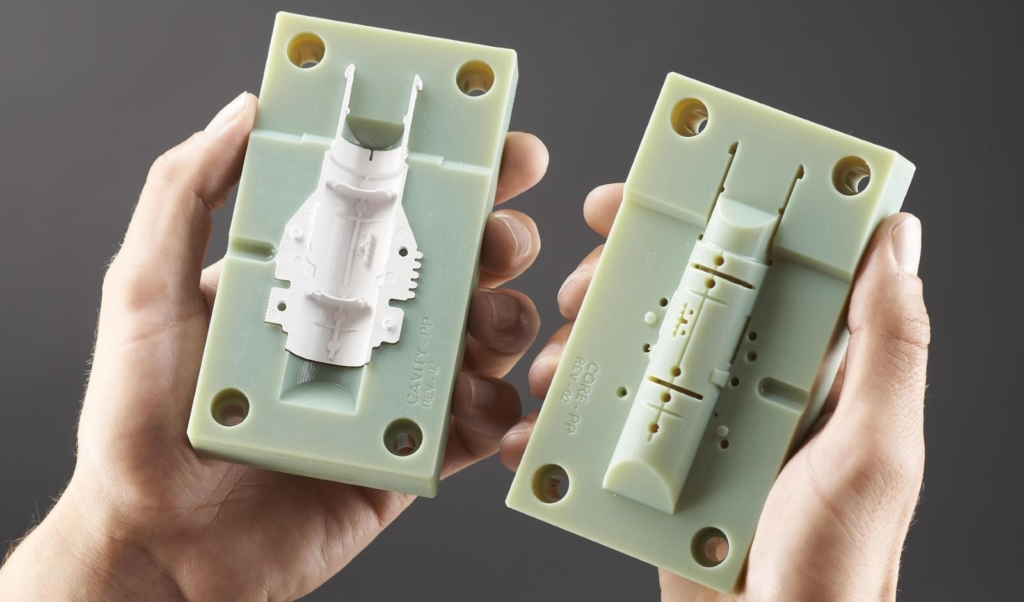

- Stereolithography (SLA) – High-precision 3D printing

- CNC Machining – Accurate and repeatable prototypes

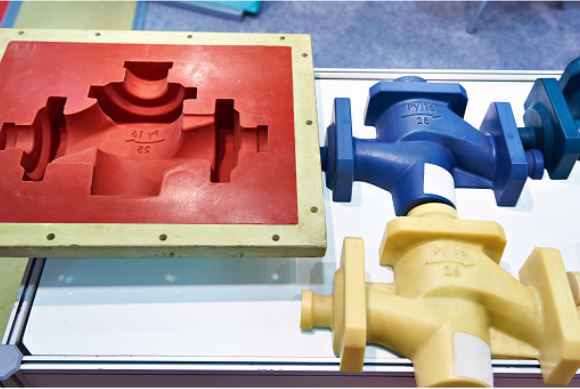

- Vacuum (urethane) Casting – Small batch production of plastic parts

- Selective Laser Sintering (SLS) – Durable 3D printed parts

- Fused Deposition Modelling (FDM) – Fast, cost-effective prototypes

- Rapid Injection Moulding – Functional prototypes in production-grade materials

6 Advantages of Rapid Prototyping

1. Accelerated Product Development

Rapid prototyping allows teams to quickly turn ideas into tangible products. Faster development cycles help bring products to market sooner, giving companies a competitive advantage.

2. Test Design Functionality Early

Prototypes enable functional testing of product parts and assemblies. This ensures form, fit, and function align with the intended design before committing to mass production.

3. Evaluate Ergonomics and User Experience

Rapid prototyping helps designers optimize ergonomics, grip, usability, and overall user experience. Physical prototypes allow for testing the placement of controls, surface textures, and comfort levels.

4. Avoid Costly Mistakes

Identifying design flaws early reduces manufacturing errors and prevents expensive revisions during full-scale production, saving both time and money.

5. Present Concepts to Stakeholders

Physical prototypes allow teams to demonstrate designs to clients, investors, or board members. Tangible models often communicate ideas more effectively than sketches or digital renderings, facilitating faster approval and feedback.

6. Low-Volume Production

Beyond prototyping, RP techniques like vacuum casting and 3D printing can produce small batches of products to meet initial market demand or pre-launch testing.

Potential Drawbacks of Rapid Prototyping

While RP offers significant advantages, it’s essential to consider potential challenges:

- Limited Material Options – Some methods restrict the types of materials available, which may affect performance compared to the final product.

- High Initial Costs – Advanced RP methods such as metal 3D printing or rapid injection molding can be expensive.

- Delayed Development – Over-reliance on repeated prototyping without clear objectives may slow down the development process.

Best Practices for Optimal Rapid Prototyping Results

1. Set Clear Goals

Define what you want to achieve—testing features, validating design concepts, or creating a minimum viable product (MVP).

2. Adopt an Iterative Approach

Use RP to refine designs through continuous testing and feedback, ensuring the final product meets user needs.

3. Choose the Right Tools

Select software and hardware tools suited to the complexity and fidelity of your prototype. Options range from CAD software to advanced 3D printers.

4. Understand Material Properties

Each prototyping material has strengths, limitations, and specific applications. Understanding these ensures prototypes are functional and representative.

5. Streamline the Process

Use templates, modular components, or automation to expedite prototyping. Efficient workflows save time and reduce errors.

Rapid prototyping is a powerful strategy to accelerate product development, improve design accuracy, and reduce costs. Whether creating a functional prototype or small batch production, RP ensures you validate ideas early and effectively. Start leveraging rapid prototyping to transform your product development process today.

At Ze-tech Mold, we provide end-to-end rapid prototyping solutions, supported by 3D printing, CNC machining, vacuum casting, and rapid injection molding. Whether you need a functional prototype, low-volume production, or pre-launch testing, our engineering team ensures high-quality results with fast turnaround and optimized efficiency.

📩 Contact Ze-tech Mold today to discuss your rapid prototyping project and discover how we can help you accelerate product development and validate your designs.