CNC machining is one of the most versatile and precise manufacturing methods used in industries ranging from aerospace to consumer electronics. However, design decisions made in the early stages often determine 70–80% of the final cost of a part. That is why Design for Manufacturability (DFM) is critical: by aligning part geometry, material selection, and tolerances with machining capabilities, engineers can reduce cycle time, minimize tool wear, and avoid unnecessary secondary operations.

This article explains the key cost drivers in CNC machining, provides DFM strategies to minimize them, and summarizes everything into a practical reference table.

Major Cost Drivers in CNC Machining

- Geometry Complexity

- Deep pockets, undercuts, and sharp internal corners require special tooling or multiple setups.

- Thin walls and tall features increase vibration and risk of deflection.

- Material Choice

- Hard-to-machine alloys (e.g., Inconel, titanium) increase tool wear and machining time.

- Dense materials (stainless steel) require slower feed rates compared to aluminum or plastics.

- Tolerance and Surface Finish

- Tight tolerances (< ±0.01 mm) significantly raise inspection time and scrap risk.

- High cosmetic finishes (Ra < 0.4 µm) require polishing or grinding beyond CNC milling/turning.

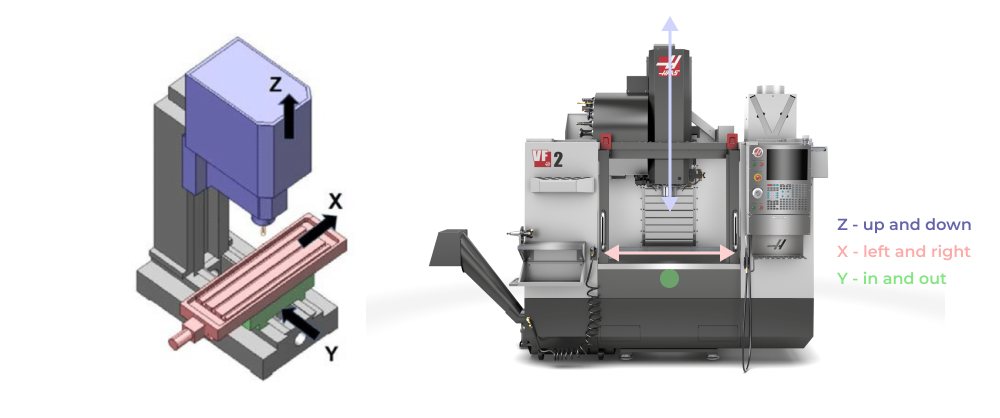

- Setup and Fixturing

- Multi-axis setups or frequent re-clamping increase cycle time.

- Custom fixtures add non-recurring engineering (NRE) cost.

- Volume and Batch Size

- Low-volume runs have higher per-unit cost due to programming, setup, and tool amortization.

- At higher volumes, automated pallet changers and optimized tool paths reduce per-part cost.

DFM Strategies to Save Cost

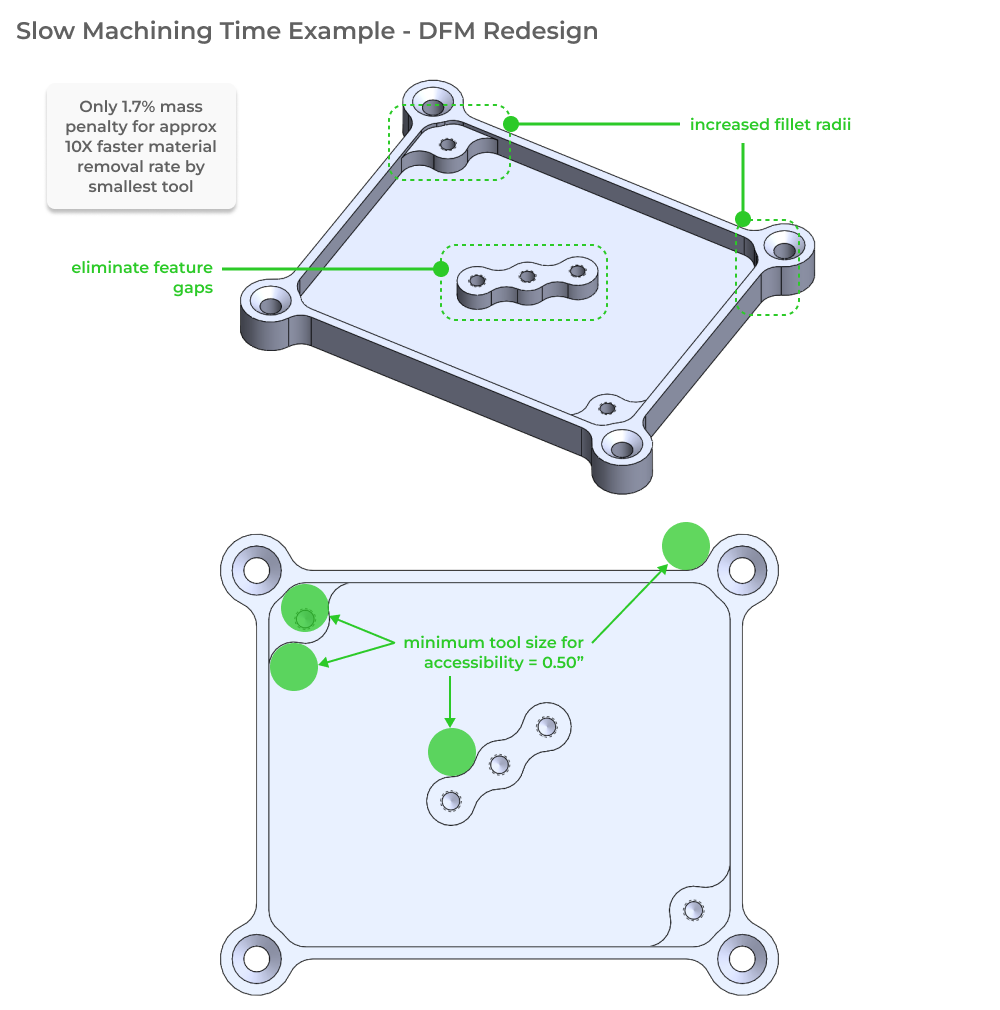

1. Simplify Geometry

- Avoid deep cavities—use standard pocket depths (≤ 4× tool diameter).

- Replace sharp internal corners with radii (≥ 1.5× tool radius).

- Minimize undercuts—design open features where possible.

2. Optimize Wall Thickness & Features

- Keep wall thickness ≥ 1.0 mm (plastics) or ≥ 2.0 mm (metals) for rigidity.

- Avoid unnecessary thin fins, sharp protrusions, or very tall features.

3. Select Machinable Materials

- Choose 6061-T6 aluminum or mild steels for prototypes and general applications.

- Reserve titanium, Inconel, or hardened steels only when performance requires.

4. Balance Tolerances with Function

- Apply tight tolerances only to critical functional features (fits, sealing surfaces).

- Use standard GD&T callouts for non-critical dimensions.

5. Design for Fixturing Efficiency

- Include flat reference surfaces for clamping.

- Consider symmetry or standard datums to reduce re-orientation.

- For multi-axis parts, ensure accessibility for cutting tools.

6. Leverage Volume Production

- Consolidate parts when feasible to reduce assemblies.

- Standardize features across families of parts.

- Use modular fixtures and quick-change tooling for higher throughput.

Cost Impact Table — CNC Machining DFM Reference

| Design Factor | Poor Practice (High Cost) | DFM-Oriented Practice (Cost Saving) | Typical Cost Impact |

|---|---|---|---|

| Geometry | Deep, narrow cavities; sharp internal corners; undercuts | Moderate depths; fillets ≥1.5× tool radius; open features | Up to 30% reduction in cycle time |

| Wall Thickness | <1 mm walls (plastics) or <2 mm (metals) | ≥1 mm plastics, ≥2 mm metals | Avoids chatter, lowers scrap risk |

| Material | Exotic alloys without necessity | Aluminum 6061, mild steels, machinable plastics | Tooling cost ↓, machining time ↓ |

| Tolerances | ±0.005 mm everywhere | Tight tolerances only on critical features | Reduces inspection & rework cost |

| Fixturing | Asymmetric, irregular shapes needing custom jigs | Flat reference surfaces, accessible features | 10–20% less setup time |

| Surface Finish | Ra < 0.4 µm everywhere | Functional areas polished only, others left standard | Avoids secondary finishing |

| Batch Size | Small lots, unique setups each run | Standardized features, batch optimization | Spreads NRE across parts |

Practical Example

Imagine a medical device housing with tight tolerances on all holes, deep internal cavities, and a titanium alloy. Such a design could cost 3–4× more than a functionally equivalent design in aluminum with selective tolerances and simplified cavities. Early collaboration between design engineers and machinists could cut the total cost by 50% without sacrificing functionality.

Conclusion

Effective Design for Manufacturability (DFM) is the fastest way to cut CNC machining costs without compromising performance. By simplifying geometry, selecting machinable materials, optimizing tolerances, and designing for efficient fixturing, engineers not only save money but also shorten lead times and improve reliability.

For organizations, embedding DFM into the design workflow ensures fewer revisions, better supplier communication, and long-term cost competitiveness.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.