In sheet metal fabrication, precision and consistency are crucial. Whether the application is in aerospace, automotive, medical devices, or consumer electronics, even the slightest deviation in dimensions, surface finish, or material integrity can lead to product failure and significant financial losses. This is why quality control (QC) plays a central role in ensuring that fabricated parts meet strict requirements before they reach the customer.

This article explores the key aspects of quality control in sheet metal fabrication, from inspection methods to material testing, and how manufacturers ensure reliability at every stage.

Importance of Quality Control in Sheet Metal Fabrication

- Customer Satisfaction: Ensures final products meet functional and aesthetic requirements.

- Cost Reduction: Detecting defects early avoids costly rework or scrap.

- Compliance: Many industries, such as aerospace and medical, require adherence to international standards (e.g., ISO 9001, AS9100).

- Reliability & Safety: Defective parts could lead to equipment malfunction or accidents.

Key Stages of Quality Control

| Stage | Method | Purpose | Tools/Equipment |

|---|---|---|---|

| Incoming Material Inspection | Verify material certificates, dimensions, and surface finish | Ensure raw materials meet specs | Vernier calipers, spectrometers |

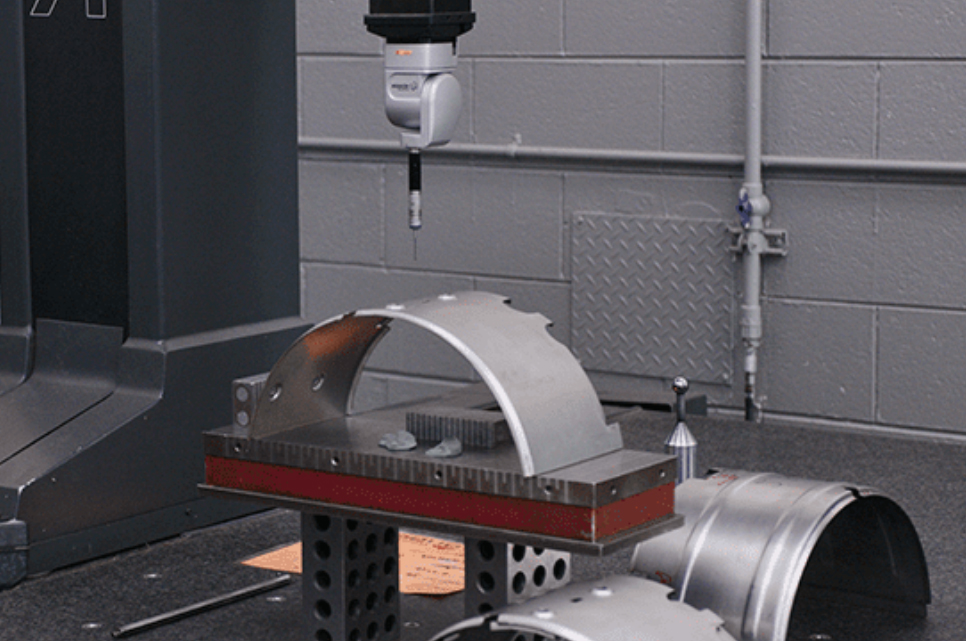

| In-Process Inspection | Check parts during fabrication (cutting, bending, welding) | Prevents cumulative errors | CMM (Coordinate Measuring Machine), gauges |

| Final Dimensional Inspection | Validate finished product tolerances | Ensure compliance with drawings | CMM, laser scanners |

| Surface Finish Inspection | Evaluate coating, painting, or anodizing quality | Aesthetic and corrosion resistance | Gloss meters, microscopes |

| Mechanical Testing | Check tensile strength, hardness, fatigue | Guarantee durability | UTM (Universal Testing Machine), hardness tester |

| Non-Destructive Testing (NDT) | Identify hidden cracks or defects without damaging part | Ensure structural integrity | Ultrasonic testing, X-ray, dye penetrant |

Common Inspection and Testing Methods

- Visual Inspection: First step to identify obvious defects like scratches, dents, or misalignments.

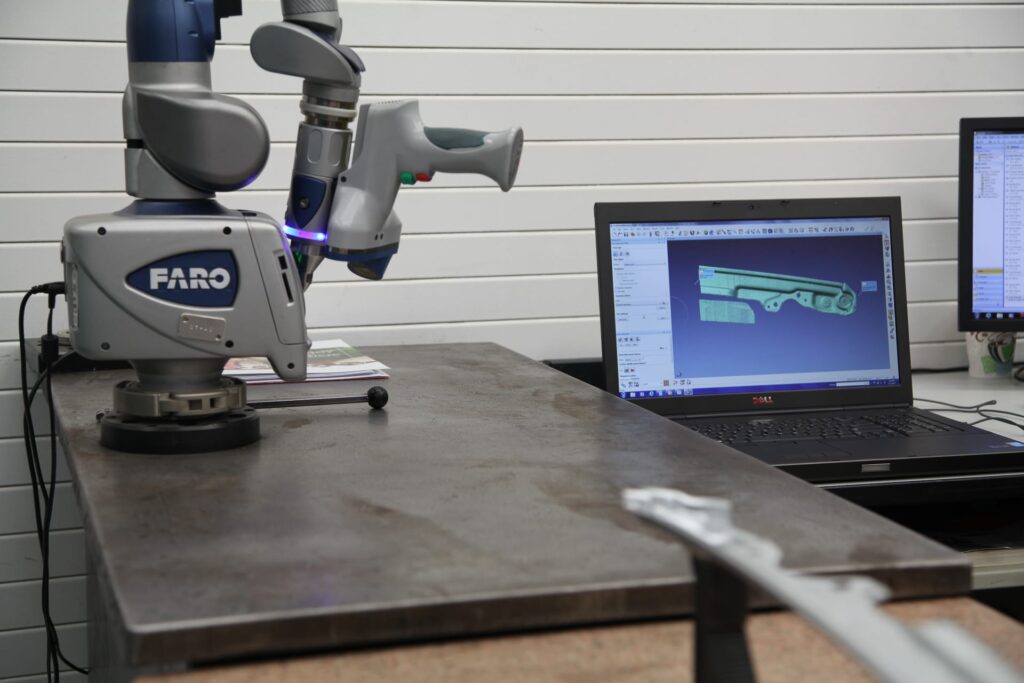

- Dimensional Verification: Using CMM, calipers, and micrometers to check tolerances.

- Flatness & Alignment Testing: Critical in assemblies where precise mating is required.

- Coating Thickness Measurement: Ensures powder coating or anodizing meets corrosion resistance requirements.

- Non-Destructive Testing (NDT): Detects hidden cracks, porosity, or welding flaws without destroying the part.

Digital Transformation in Quality Control

With Industry 4.0 adoption, quality control has evolved from manual inspection to data-driven and automated methods:

- Automated Optical Inspection (AOI) with cameras and AI algorithms.

- Digital Twins to simulate fabrication and detect potential failures before production.

- Real-Time Monitoring with IoT-enabled sensors during machining, bending, and welding.

This shift reduces human error and speeds up the QC process while maintaining consistency.

Conclusion

Quality control is not just a final step, but an integral part of sheet metal fabrication. From material inspection to advanced non-destructive testing, each layer of QC ensures that products are reliable, safe, and cost-effective.

As industries demand lighter, stronger, and more complex sheet metal parts, manufacturers who invest in rigorous QC processes and digital technologies will maintain a competitive advantage.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.