Injection molding is one of the most widely used manufacturing processes for producing plastic parts at scale. However, achieving high-quality, cost-effective, and durable molded components requires careful Design for Manufacturability (DFM). Engineers must consider multiple design elements—such as draft angles, wall thickness, ribs, fillets, and gating—early in the product development cycle to avoid costly tooling changes and manufacturing defects.

In this article, we explore key design principles for plastic injection molding and how they impact product performance and manufacturability.

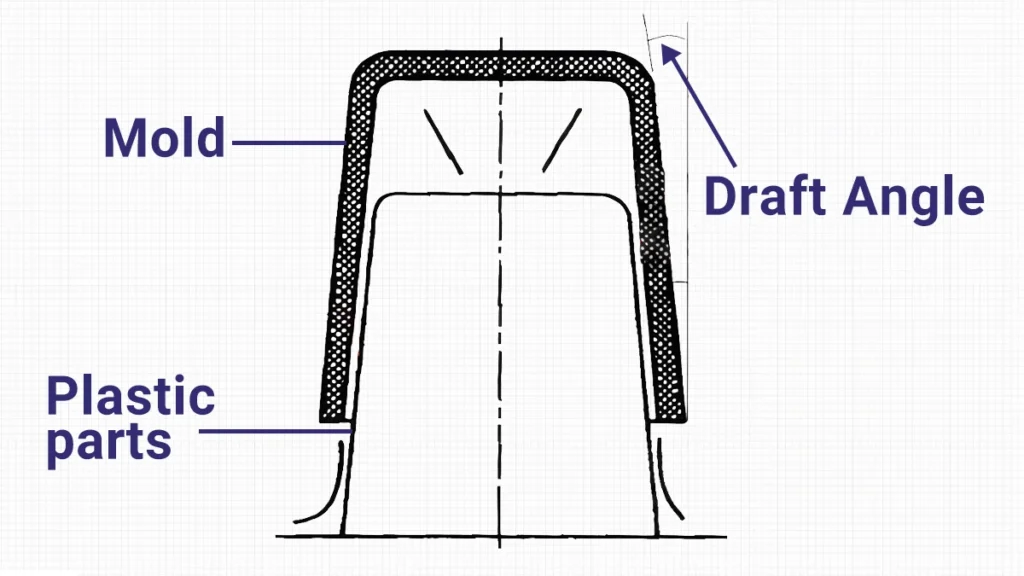

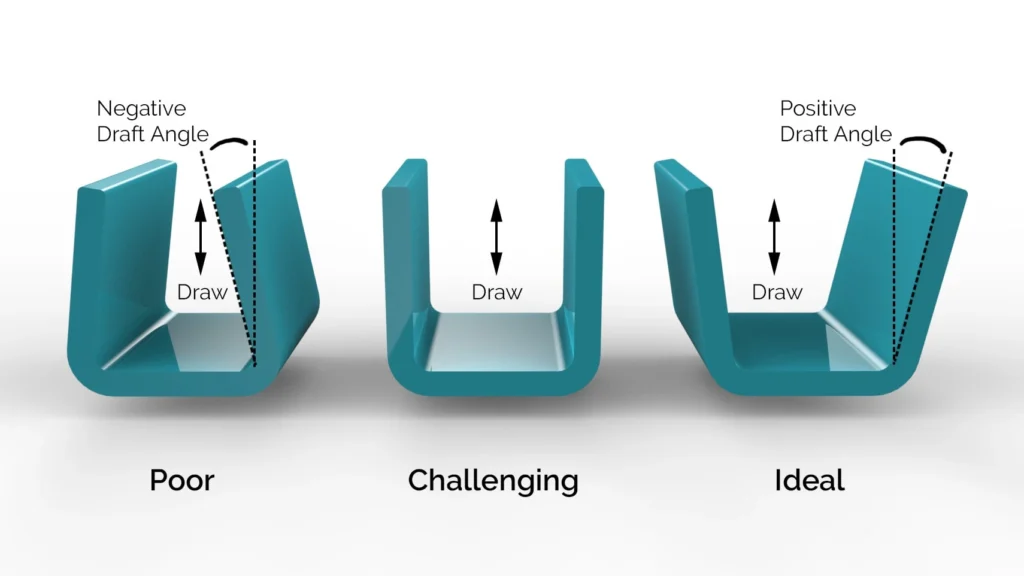

1. Draft Angles: Enabling Smooth Part Ejection

Draft angles are the slight tapers applied to vertical surfaces of a molded part, typically 1°–3° per side. Without draft, parts may stick to the mold, causing surface scratches, warpage, or even mold damage.

- Too little draft → parts drag against mold walls, requiring higher ejection force.

- Too much draft → part aesthetics may suffer, but manufacturability improves.

Tip: Always include draft in CAD designs early, since adding it later may require reworking mold cavities.

2. Wall Thickness: Balancing Strength and Manufacturability

Uniform wall thickness is critical to avoid defects such as sink marks, voids, and warpage.

- Thin walls (<0.5 mm) risk short shots (incomplete filling).

- Thick walls (>4 mm) increase cycle time and cooling stress.

- Recommended wall thickness varies by material (e.g., ABS: 1.2–3.5 mm, Nylon: 0.8–3.0 mm).

Maintaining consistent wall sections ensures predictable cooling and dimensional stability.

3. Ribs and Bosses: Reinforcement Without Excessive Thickness

Instead of thick walls, ribs provide structural support while minimizing material use. Ribs should be about 50–60% of wall thickness and have rounded bases to avoid stress concentration.

Bosses, typically used for fasteners or inserts, should be designed with supporting ribs to prevent cracking.

4. Fillets and Radii: Reducing Stress Concentrations

Sharp corners cause stress buildup and hinder plastic flow. Adding fillets improves both aesthetics and mechanical strength.

- Recommended inside radius: ≥0.5 × wall thickness.

5. Gate and Flow Considerations

Proper gate location ensures even filling and reduces weld lines. Designers should:

- Avoid gating into thin sections.

- Place gates to promote balanced flow.

- Consider hot runner vs. cold runner systems depending on volume.

📊 Design Guidelines Summary Table

| Feature | Recommended Practice | Common Defects if Ignored | Example Dimensions |

|---|---|---|---|

| Draft Angles | 1°–3° per side (min.) | Ejection issues, surface scratches | 2° typical for ABS parts |

| Wall Thickness | Uniform, material-specific | Sink marks, voids, warpage | ABS: 1.2–3.5 mm |

| Ribs | 50–60% of wall thickness | Sink marks, cracking at base | Rib thickness = 0.6 × wall |

| Bosses | Add supporting ribs, avoid isolated thick bosses | Cracking, sink marks | Boss OD = 2 × screw OD |

| Fillets | Inside radius ≥ 0.5 × wall thickness | Stress concentration, cracks | 1 mm for 2 mm wall |

| Gate Placement | Balanced flow, avoid thin entry points | Weld lines, short shots | Edge gate at thick wall |

Conclusion

Designing plastic parts for injection molding is a delicate balance of geometry, material behavior, and manufacturing constraints. By incorporating draft angles, optimized wall thickness, ribs, fillets, and thoughtful gating, engineers can significantly reduce defects, shorten cycle times, and extend mold life.

Integrating these guidelines into the design phase not only improves product reliability but also reduces overall manufacturing cost. For startups and OEMs, investing time in Design for Manufacturability (DFM) upfront ensures smoother production and faster time-to-market.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.