Introduction

The demand for lightweight materials in electric vehicles (EVs) and aerospace engineering has never been greater. Reducing weight directly translates into improved fuel efficiency, extended battery range, lower emissions, and enhanced performance. At the same time, sustainability pressures are driving industries to adopt materials that are not only strong and light but also environmentally responsible.

This blog explores the role of lightweight materials in EVs and aerospace, compares different options, and explains how they enable efficiency and sustainability.

Why Lightweight Materials Matter

- Energy Efficiency: Lighter vehicles and aircraft consume less energy to move, extending range and reducing fuel costs.

- Environmental Impact: Reducing weight lowers CO₂ emissions in aerospace and extends EV battery lifespan, reducing reliance on frequent replacements.

- Performance Benefits: Materials like carbon fiber and titanium provide high strength-to-weight ratios, improving safety and performance under extreme conditions.

- Sustainability: Many lightweight materials are recyclable, aligning with circular economy principles.

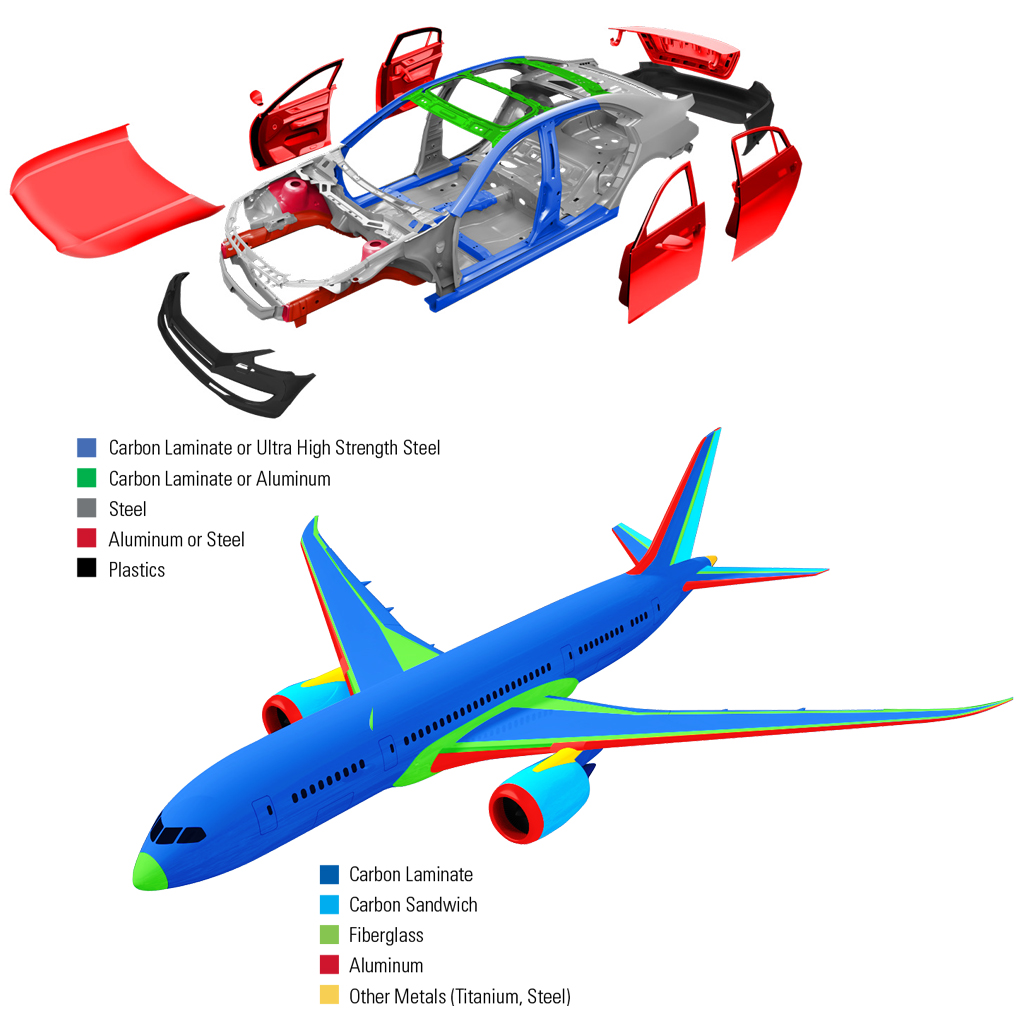

Key Lightweight Materials in EVs and Aerospace

| Material | Applications in EVs | Applications in Aerospace | Strength-to-Weight Advantage | Sustainability Notes |

|---|---|---|---|---|

| Aluminum Alloys | Battery enclosures, chassis, body panels | Fuselage components, wing structures | High; ~1/3 the weight of steel | Highly recyclable with low energy remelting cost |

| Magnesium Alloys | Steering wheels, transmission housings, brackets | Gearbox casings, seating frames | 75% lighter than steel, lighter than aluminum | Abundant, recyclable, but energy-intensive extraction |

| Carbon Fiber Reinforced Polymers (CFRP) | Body panels, structural reinforcements | Primary structures, tail fins, rotor blades | Very high strength-to-weight ratio | Recyclability improving but limited |

| Titanium Alloys | Battery casings, high-stress fasteners | Jet engines, landing gear, structural joints | High strength, corrosion-resistant | Expensive but long service life offsets cost |

| Advanced Composites (Hybrid/Glass Fiber) | EV interiors, insulation panels | Cabin structures, secondary supports | Good balance of strength and weight | Some are recyclable, others require specialized processes |

Industry Examples

- EVs: Tesla, Rivian, and other EV manufacturers increasingly rely on aluminum-intensive designs to extend driving range while experimenting with carbon composites for body panels.

- Aerospace: Boeing 787 Dreamliner and Airbus A350 use more than 50% composite materials by weight, significantly reducing fuel consumption.

- Cross-Sector Innovation: Magnesium alloys, once avoided due to flammability concerns, are now used safely in both aerospace and EV applications thanks to new alloying techniques.

Sustainability Considerations

While lightweighting is beneficial for energy efficiency, material lifecycle management is equally critical:

- Recycling aluminum saves up to 95% of the energy compared to primary production.

- Research in carbon fiber recycling technologies is making composite reuse more feasible.

- Circular design strategies, including modular assembly, enable easier material recovery.

Conclusion

Lightweight materials are not just about performance — they are central to the future of sustainable mobility and aviation. As EVs and aerospace manufacturers race toward net-zero emissions, material innovations will remain at the core of improving efficiency, extending product lifecycles, and reducing environmental impact.

The industries that successfully integrate lightweight and sustainable materials will be those that set the pace in the global transition toward greener transportation.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.