Introduction

In the evolving landscape of advanced manufacturing, hybrid manufacturing has emerged as a transformative approach that combines the precision of CNC machining with the flexibility of additive manufacturing (AM), or 3D printing. This powerful synergy allows manufacturers to achieve higher complexity, tighter tolerances, faster production cycles, and improved cost efficiency.

By leveraging the best of both subtractive and additive processes, hybrid manufacturing enables new design possibilities and production strategies that were not feasible before.

What Is Hybrid Manufacturing?

Hybrid manufacturing integrates two fundamental processes:

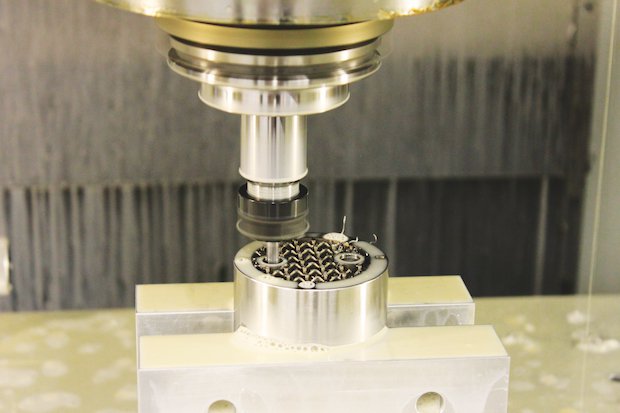

- Additive Manufacturing (3D Printing): Builds components layer by layer, enabling complex geometries, internal channels, and lightweight designs.

- CNC Machining: Removes material with precision cutting tools, ensuring high accuracy, smooth finishes, and compliance with strict tolerances.

By combining these two, manufacturers can print near-net-shape parts and then finish them with CNC machining to achieve required dimensions, surface finishes, and performance standards.

Key Benefits of Hybrid Manufacturing

| Benefit | Additive Manufacturing Contribution | CNC Machining Contribution | Hybrid Advantage |

|---|---|---|---|

| Complex Geometries | Create lattice structures, internal cooling channels | Finish critical surfaces, threads, and interfaces | Functional parts with advanced geometries and tight tolerances |

| Material Efficiency | Minimizes waste by adding material only where needed | Removes only excess for final shape | Reduced scrap compared to traditional machining |

| Time-to-Market | Rapid prototyping and near-net-shape builds | Fast finishing and accuracy improvements | Shorter product development cycles |

| Customization | Enables one-off and highly customized parts | Ensures consistency in interfaces and assemblies | Mass customization with precision |

| Repair & Remanufacturing | Adds material to worn/damaged parts | Restores dimensions and tolerances | Sustainable repair of high-value components |

Real-World Applications

- Aerospace Industry

- Printing complex engine parts with internal cooling channels, then machining sealing surfaces for performance reliability.

- Medical Devices

- Creating patient-specific implants with 3D printing, followed by CNC finishing for biocompatible surfaces.

- Automotive Manufacturing

- Hybrid processes are used to prototype lightweight structural parts, accelerating innovation in EVs and high-performance cars.

- Tooling and Mold Making

- Additive processes build conformal cooling channels into molds, while CNC ensures precise cavity dimensions.

Challenges in Hybrid Manufacturing

While promising, hybrid manufacturing also presents challenges:

- High Capital Costs: Advanced hybrid systems can be expensive to acquire and maintain.

- Process Integration: Ensuring seamless transitions between additive and subtractive stages requires advanced software and controls.

- Material Limitations: Not all materials are equally suited for both AM and CNC processes.

- Skilled Workforce Needs: Operators must understand both additive design and CNC machining principles.

The Future of Hybrid Manufacturing

As Industry 4.0 and smart manufacturing evolve, hybrid manufacturing is expected to become more widespread, driven by:

- Integration with AI-driven design optimization.

- Enhanced multi-material capabilities.

- Stronger focus on sustainability through reduced waste and part repairability.

- Adoption in on-demand, decentralized manufacturing networks.

Conclusion

Hybrid manufacturing represents the future of high-precision, efficient, and innovative production. By combining the design freedom of 3D printing with the accuracy of CNC machining, companies can achieve the best of both worlds—pushing the boundaries of what’s possible in aerospace, medical, automotive, and tooling industries.

For manufacturers seeking faster time-to-market, reduced waste, and increased competitiveness, hybrid manufacturing is not just an option—it’s a necessity for the future.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.