Introduction

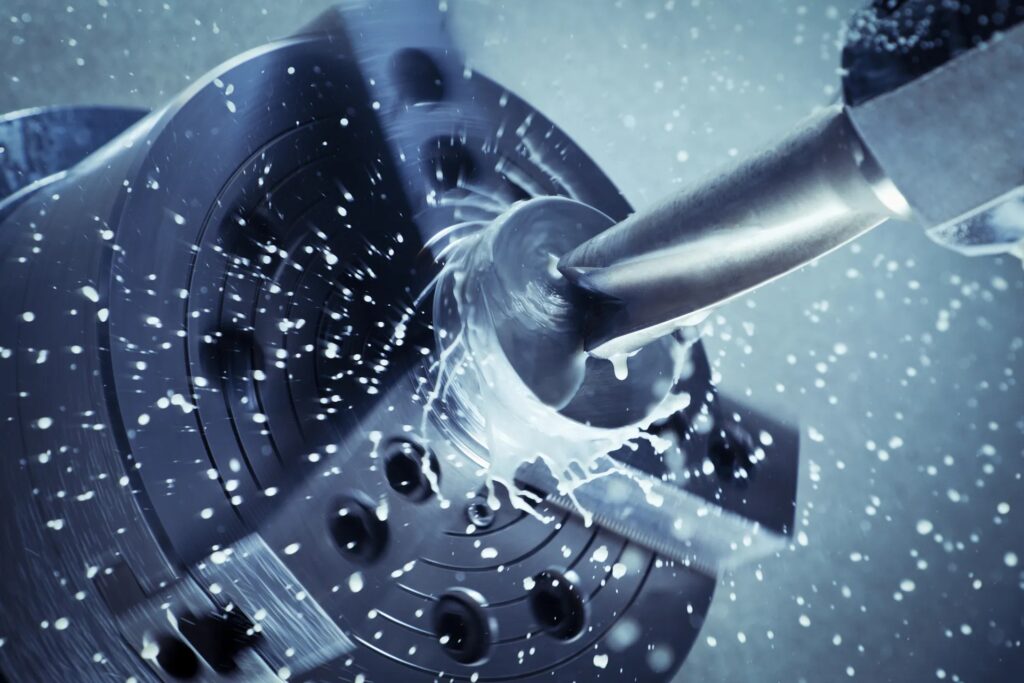

In high-precision manufacturing, achieving micron-level tolerances is not a luxury—it’s a necessity. From aerospace components to medical implants, precision determines product performance, reliability, and safety. CNC machining has become the cornerstone of achieving these ultra-tight tolerances through advanced technology, automation, and process control.

Understanding Precision and Tolerance

Precision refers to how repeatable a machining process is, while tolerance defines the permissible deviation from the nominal dimension. The tighter the tolerance, the greater the precision required from both machine and operator.

| Term | Definition | Typical Range |

|---|---|---|

| Precision | Consistency of repeated measurements | ±1 µm – ±10 µm |

| Tolerance | Allowable variation in part dimensions | ±5 µm – ±50 µm |

| Accuracy | Closeness to the true value | ±2 µm – ±20 µm |

Key Factors Influencing Precision

Achieving micron-level accuracy is a combination of machine capability, environmental control, and process optimization.

| Factor | Description | Impact |

|---|---|---|

| Machine Rigidity | Stability reduces vibration and deformation | Prevents dimensional drift |

| Thermal Stability | Temperature fluctuations cause expansion/contraction | Affects size and tolerance |

| Tool Wear | Gradual tool degradation alters part geometry | Reduces repeatability |

| Material Properties | Hardness and elasticity influence machining response | Affects surface finish |

| Metrology Equipment | High-precision CMMs and laser scanners | Enables verification at micron level |

Technologies Enabling Micron Accuracy

Modern CNC systems are equipped with cutting-edge technologies to maintain extreme precision:

- Linear Encoders: Provide feedback at sub-micron levels.

- Closed-loop Control Systems: Automatically correct positional errors.

- Thermal Compensation: Adjusts for temperature variations in real-time.

- High-speed Spindles: Reduce tool pressure and maintain consistent cutting forces.

- AI-Based Monitoring: Predicts tool wear and compensates proactively.

Quality Assurance and Metrology

To validate micron-level tolerances, manufacturers use advanced measurement systems such as:

| Inspection Method | Equipment Used | Accuracy Level |

|---|---|---|

| Coordinate Measurement | CMM (Contact/Non-contact) | ±1 µm |

| Optical Profiling | Laser Interferometer | ±0.5 µm |

| Surface Roughness Testing | Profilometer | Ra < 0.1 µm |

| In-Process Monitoring | Probes & Sensors | ±2 µm |

Applications Where Micron Precision Matters

- Aerospace: Turbine blades, fuel injection components.

- Medical Devices: Implants, surgical instruments.

- Semiconductors: Micro molds and wafer processing tools.

- Optics: Lenses, precision mounts, and housings.

Conclusion

Precision in CNC machining goes beyond machine specifications—it’s an integration of engineering discipline, environmental control, and digital feedback systems. As demand for tighter tolerances continues, the fusion of AI, metrology, and advanced materials will define the future of precision manufacturing.

At Ze-tech Mold, we offer a range of high-quality solutions including vacuum casting, CNC machining, 3D printing, die casting, and more. We provide a one-stop service for your custom part production projects, covering design, production, and transportation, turning your ideas into reality.

To start your next project, simply send your CAD design to our website contact form, and our engineering team will provide a quote.