Introduction

In the world of precision manufacturing, choosing the right plastic material can make the difference between a good product and a great one. Among the many options available—such as polycarbonate (PC), ABS, and nylon—acrylic (PMMA, polymethyl methacrylate) stands out as the material of choice for CNC machining.

Known for its crystal-clear transparency, excellent machinability, and dimensional stability, acrylic has earned its nickname: the “King of Plastics.” But what makes PMMA so uniquely suited for CNC applications, and how does it compare with other materials?

What Is Acrylic (PMMA)?

Acrylic, or polymethyl methacrylate, is a lightweight thermoplastic often used as a glass substitute. It’s valued for its optical clarity (up to 92% light transmission), weather resistance, and ease of fabrication. PMMA is available in both cast and extruded forms—each offering distinct machining characteristics.

| Property | Description |

|---|---|

| Density | 1.18 g/cm³ |

| Transparency | Up to 92% light transmission |

| Hardness (Rockwell) | M95 |

| Operating Temperature | -40°C to +80°C |

| Form Types | Cast PMMA (better surface finish) / Extruded PMMA (cheaper, easier to machine) |

Why Acrylic Is Ideal for CNC Machining

1. Outstanding Machinability

Acrylic machines exceptionally well using CNC routers, mills, and lathes. Its low internal stress and consistent hardness enable precise cuts and smooth edges without cracking or chipping. Compared to materials like polycarbonate, PMMA produces cleaner chips and less tool wear, resulting in better surface finishes and longer tool life.

2. Superior Optical Clarity

When polished, acrylic achieves a glass-like transparency, making it the go-to material for display cases, light guides, lenses, and signage. CNC machining allows for tight tolerances and intricate geometries without sacrificing optical performance—a critical advantage for optical and consumer electronics industries.

3. Dimensional Stability and Precision

PMMA maintains its shape even under tight tolerances. Its low water absorption and minimal warpage make it ideal for precision assemblies and prototypes requiring high repeatability.

4. Cost-Effective and Readily Available

Compared to polycarbonate or engineering plastics like PEEK, PMMA offers excellent cost-performance balance. It’s readily available in various sizes, colors, and finishes—reducing both lead time and material costs in production.

5. Easy Post-Processing

Acrylic can be easily polished, bonded, laser-cut, and painted. After CNC machining, components can be flame-polished or vapor-polished to achieve a crystal-clear finish, often indistinguishable from molded parts.

Cast vs. Extruded Acrylic: Which Is Better for CNC Machining?

| Feature | Cast PMMA | Extruded PMMA |

|---|---|---|

| Machining Quality | Better surface finish, less melting | Easier to cut, lower cost |

| Optical Clarity | Superior | Slightly lower |

| Thickness Availability | Wider range | Limited |

| Stress Resistance | Higher | Moderate |

Recommendation: For high-end CNC parts that demand optical clarity and dimensional precision—cast acrylic is the better choice.

Common CNC Applications of Acrylic (PMMA)

| Industry | CNC Machined Acrylic Applications |

|---|---|

| Consumer Electronics | Transparent covers, indicator panels, light diffusers |

| Automotive | Light lenses, gauge covers, trim components |

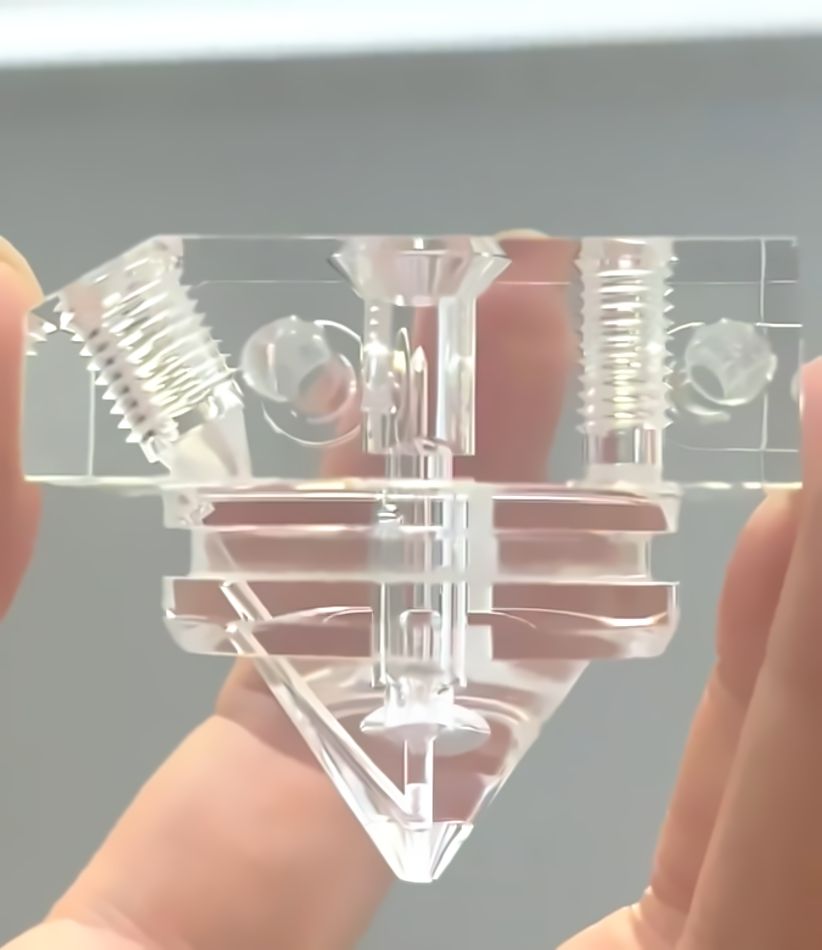

| Medical & Laboratory | Fluid manifolds, diagnostic chambers, enclosures |

| Retail & Architecture | Display stands, illuminated signage, nameplates |

| Optical & Lighting | Lenses, prisms, LED housings |

Acrylic’s versatility extends beyond its looks—it combines aesthetics with precision and performance, making it indispensable in industries that value both function and form.

Tips for CNC Machining Acrylic

- Use sharp single-flute end mills to prevent melting.

- Maintain low spindle speeds and moderate feed rates.

- Use air cooling instead of liquid coolant to avoid surface crazing.

- Polish with flame or vapor techniques for crystal clarity.

- Avoid excessive clamping pressure to prevent stress cracking.

Acrylic vs. Polycarbonate: A Quick Comparison

| Property | Acrylic (PMMA) | Polycarbonate (PC) |

|---|---|---|

| Clarity | Higher (92%) | Slightly lower (88%) |

| Impact Strength | Moderate | 30× stronger |

| Scratch Resistance | Excellent | Moderate |

| UV Resistance | Excellent | Poor without coating |

| Machinability | Easier | More prone to melting |

While polycarbonate is stronger, acrylic’s superior machinability, clarity, and cost-efficiency make it the preferred option for most CNC applications—unless extreme impact resistance is required.

Conclusion

Acrylic (PMMA) truly deserves its reputation as the “King of Plastics” for CNC machining.

It combines beauty, precision, and practicality—offering optical-grade transparency, stable dimensional properties, and outstanding machinability.

Whether you’re creating prototype components, architectural models, or optical housings, acrylic delivers a professional finish that few materials can match.

At Ze-tech Mold, we specialize in CNC machining of acrylic and other engineering plastics, offering high-quality prototypes and production parts with tight tolerances and optical-grade finishes.

👉 Contact us today to explore how we can bring your acrylic parts to life with precision CNC technology.