At Ze-tech Mold, face milling is one of our most frequently used CNC operations for creating flat, smooth, and dimensionally accurate surfaces on prototypes and production parts. Whether you’re preparing mating surfaces, reducing stock, or achieving mirror-like finishes, face milling is a cornerstone of precision manufacturing. In this expert guide, we’ll define what face milling is, how it works, the best tools, and pro techniques to optimize your results — backed by our 15+ years of ISO 9001:2015-certified machining experience.

What Is Face Milling?

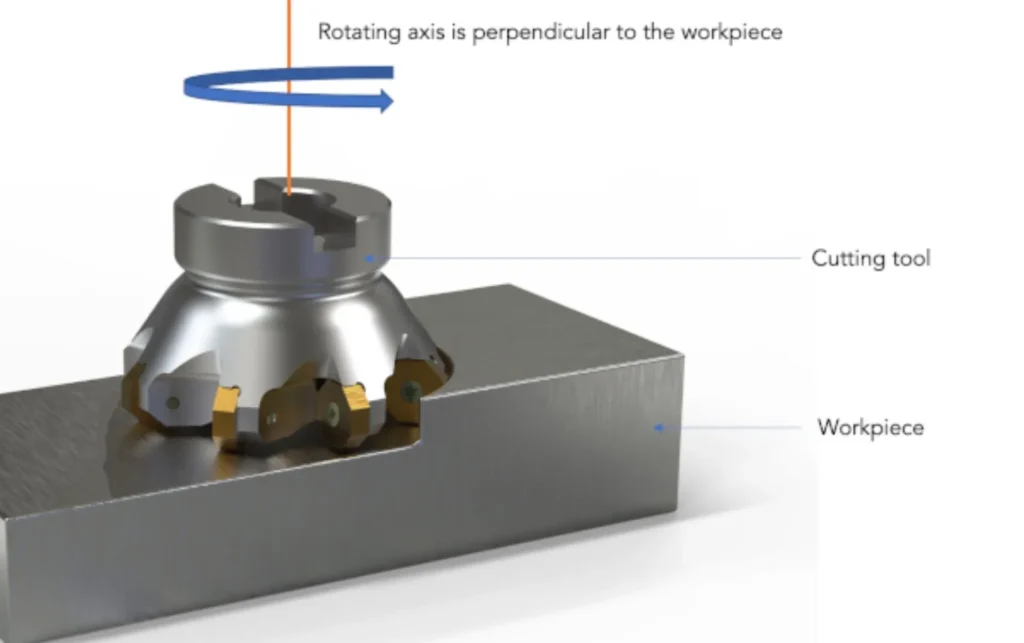

Face milling is a CNC milling process that uses a multi-tooth cutter rotating on an axis perpendicular to the workpiece to remove material and create a flat surface. Unlike peripheral (side) milling, the cutting action occurs primarily on the face (bottom) of the tool.

Primary Goal: Produce planar surfaces with tight flatness, parallelism, and surface finish. Common Applications: Squaring blocks, machining mounting faces, preparing surfaces for assembly.

How Face Milling Works

- Tool Selection – Face mill with indexable inserts (carbide, PCD, or CBN).

- Workholding – Secure part in vise, fixture, or vacuum chuck.

- Spindle Rotation – Tool spins at high RPM (1,000–20,000+).

- Feed Motion – Table moves workpiece under rotating cutter.

- Chip Removal – Coolant or air blast clears chips to prevent re-cutting.

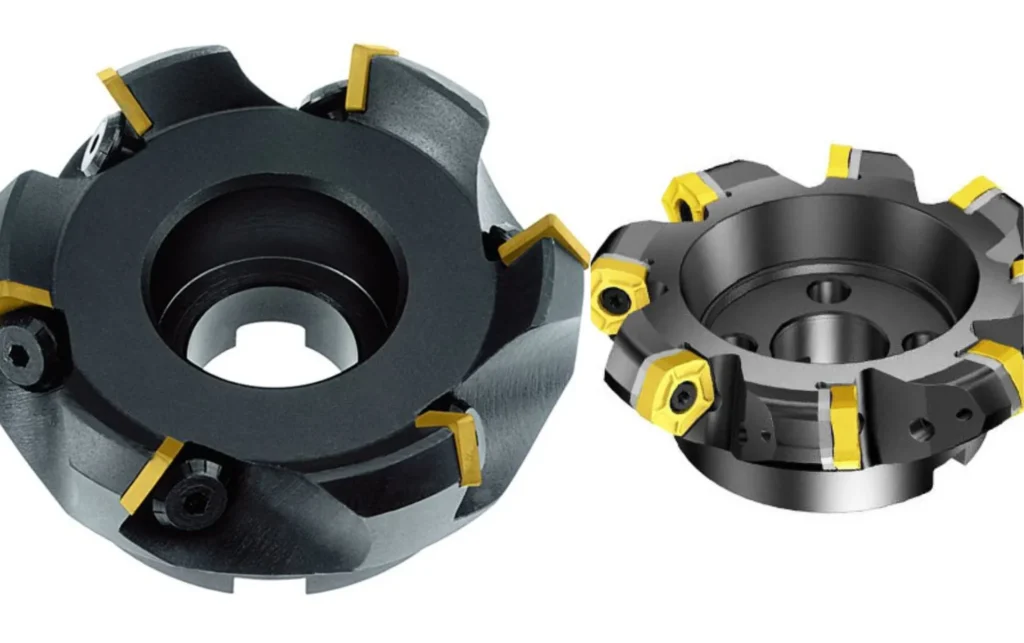

Essential Face Milling Tools

| Tool Type | Best For | Insert Material | Diameter Range |

|---|---|---|---|

| Shell Mill | Large surfaces, heavy stock removal | Carbide | 50–250 mm |

| Indexable Face Mill | General purpose, medium runs | Carbide / PCD | 25–160 mm |

| High-Feed Face Mill | Fast material removal rate (MRR) | Carbide | 35–100 mm |

| PCD Face Mill | Aluminum, composites (mirror finish) | Polycrystalline Diamond | 50–125 mm |

| Button Insert Mill | 3D contours, light finishing | Carbide | 20–80 mm |

Face Milling Techniques & Pro Tips

1. Climb vs. Conventional Milling

| Method | Surface Finish | Tool Life | When to Use |

|---|---|---|---|

| Climb Milling | ★★★★★ | ★★★★ | Finishing passes |

| Conventional | ★★★ | ★★★★★ | Roughing, hard materials |

Tip: Use climb milling for finishing to reduce burrs and improve flatness.

2. Stepover (Ae) Optimization

- Roughing: 70–90% of cutter diameter

- Finishing: 10–30% for superior surface

- Rule of Thumb: Ae ≤ 0.7 × Dc to avoid vibration

3. Depth of Cut (Ap)

- Max Ap = 0.7 × insert length

- For aluminum: Ap up to 5mm per pass

- For steel: Ap 1–2mm with coolant

4. Coolant Strategy

| Material | Coolant Type |

|---|---|

| Aluminum | Flood or MQL (mist) |

| Steel | High-pressure through-spindle |

| Titanium | Emulsion + extreme pressure additives |

Common Face Milling Parameters (Examples)

| Material | Cutter Ø | RPM | Feed Rate (mm/min) | Ap (mm) | Ae (mm) | Surface Finish |

|---|---|---|---|---|---|---|

| Al 6061 | 80 mm | 8,000 | 3,200 | 3.0 | 60 | Ra 0.8 |

| Steel 4140 | 63 mm | 2,500 | 800 | 1.5 | 45 | Ra 1.6 |

| CFRP | 50 mm (PCD) | 12,000 | 2,000 | 1.0 | 35 | No delamination |

Advantages of Face Milling

- High Productivity: Removes large volumes quickly

- Excellent Flatness: Achieves ≤0.01mm over 300mm

- Superior Surface Finish: Down to Ra 0.2 μm with PCD

- Versatile: Works on metals, plastics, composites

Face Milling in Ze-tech Mold Projects

We use face milling daily for:

- Medical device bases (titanium, Ra 0.4)

- Aerospace mounting plates (aluminum, ±0.005mm flatness)

- Automotive battery trays (high-feed roughing + finish pass)

- Robotic end effectors (CFRP lightweight faces)

Client Result: Reduced surface prep time by 40% using optimized face milling before anodizing.

Why Choose Ze-tech Mold for Face Milling?

- 50+ CNC Machines (3-, 4-, 5-axis)

- In-House Tool Library – Sandvik, Kennametal, Mitsubishi

- Free DFM Analysis – Optimize stepover, Ap, and tool path

- 98% On-Time Delivery | 10,000+ Projects Completed

- Finishing Options: Anodizing, powder coating, lapping

Ready for Flawless Flat Surfaces?

Master face milling with Ze-tech Mold. From rough stock removal to mirror finishes, we deliver precision every time.

📞 Contact Michelle Tang: 0086 18025337983