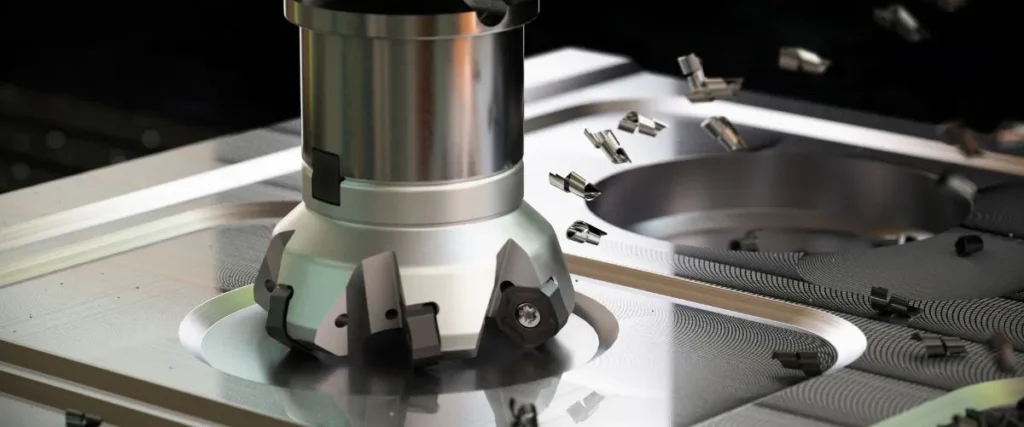

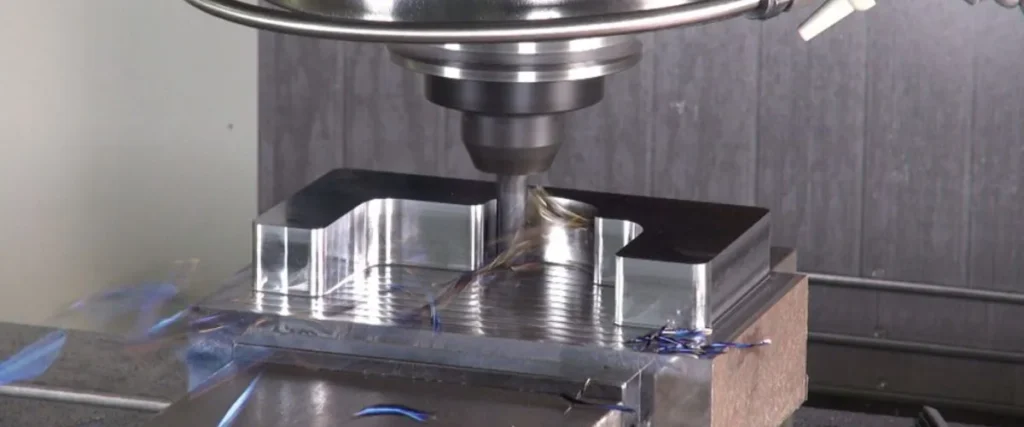

At Ze-tech Mold, end milling and face milling are the backbone of our precision CNC machining workflow. While both remove material using rotating cutters, they serve distinct purposes — one excels at 3D contours and pockets, the other at flat, expansive surfaces. Choosing the wrong process can lead to poor finish, tool breakage, or wasted time. In this expert comparison, we break down how they differ, tooling, techniques, and when to use each — all from our 15+ years of ISO 9001:2015-certified experience in medical, aerospace, automotive, and robotics parts.

Core Difference: Cutting Action

| Aspect | End Milling | Face Milling |

|---|---|---|

| Primary Cutting Edge | Side (flutes) of the tool | Face (bottom) of the tool |

| Surface Created | Slots, pockets, walls, 3D contours | Large flat surfaces, squaring blocks |

| Tool Axis | Parallel to feed direction | Perpendicular to workpiece surface |

| Typical Use | Detail work, finishing | Roughing, surfacing, stock removal |

Tooling Comparison

| Tool Type | End Mill | Face Mill |

|---|---|---|

| Geometry | Cylindrical with flutes (2–8) | Disk-shaped with indexable inserts |

| Diameter | 0.5–25 mm (common) | 25–250 mm |

| Insert Material | Solid carbide, HSS, PCD | Carbide, CBN, PCD inserts |

| Best For | Aluminum, titanium, plastics | Steel, cast iron, large aluminum plates |

| Example | 6 mm 4-flute carbide end mill | 80 mm shell mill with APKT inserts |

Process Parameters (Aluminum 6061 Example)

| Parameter | End Milling (Slotting) | Face Milling (Surfacing) |

|---|---|---|

| Cutting Speed | 200–300 m/min | 800–1,200 m/min |

| Feed per Tooth | 0.05–0.1 mm | 0.15–0.3 mm |

| Depth of Cut | 1–3× tool Ø (axial) | 1–5 mm (radial) |

| Stepover | 40–60% of Ø | 70–90% of Ø |

| Surface Finish | Ra 0.8–1.6 | Ra 0.4–0.8 |

When to Use End Milling

Choose End Milling When You Need:

- Pockets, slots, or threads

- 3D contouring (e.g., mold cavities)

- Small features (<20 mm)

- High precision in tight spaces

When to Use Face Milling

Choose Face Milling When You Need:

- Large flat areas (>100×100 mm)

- Stock removal from castings/forgings

- Mirror-like surface finish

- High material removal rate (MRR)

Pro Tip: Use high-feed face mills (e.g., 0.8 mm/tooth) for 3× faster roughing.

Hybrid Strategy: Best of Both Worlds

Many Ze-tech Mold projects combine both:

- Face mill → Remove bulk stock, flatten top surface

- End mill → Cut pockets, drill holes, finish walls

Common Mistakes to Avoid

| Mistake | Fix |

|---|---|

| Using end mill for large surfacing | → Switch to face mill |

| Face milling deep pockets | → Use end mill with ramping |

| Wrong stepover (vibration) | → Reduce Ae to 70% for face, 50% for end |

| No coolant in titanium | → Use high-pressure through-tool |

Real-World Applications at Ze-tech Mold

| Industry | End Milling | Face Milling |

|---|---|---|

| Medical | Threaded holes in implants | Flat mating surfaces |

| Aerospace | Turbine blade slots | Wing spar mounting faces |

| Automotive | Battery tray pockets | Engine block deck face |

| Robotics | Gripper finger contours | Base plate squaring |

Why Ze-tech Mold Excels in Both

- 100+ Tool Holders (BT40, HSK63)

- CAM Expertise: HyperMILL, Mastercam

- In-House Inspection: CMM flatness <0.01 mm

- Free DFM Review – We recommend the optimal process

- 98% On-Time | 10,000+ Projects

Ready to Optimize Your Milling Strategy?

Don’t guess — end mill or face mill? Let Ze-tech Mold analyze your part and deliver faster, flatter, finer results.

📞 Contact Michelle Tang: 0086 18025337983