Introduction

In the era of smart automation, robot manufacturing plays a vital role in driving innovation across industries — from automotive assembly to precision medical devices.

Behind every efficient robot lies a combination of carefully selected materials and precisely engineered components.

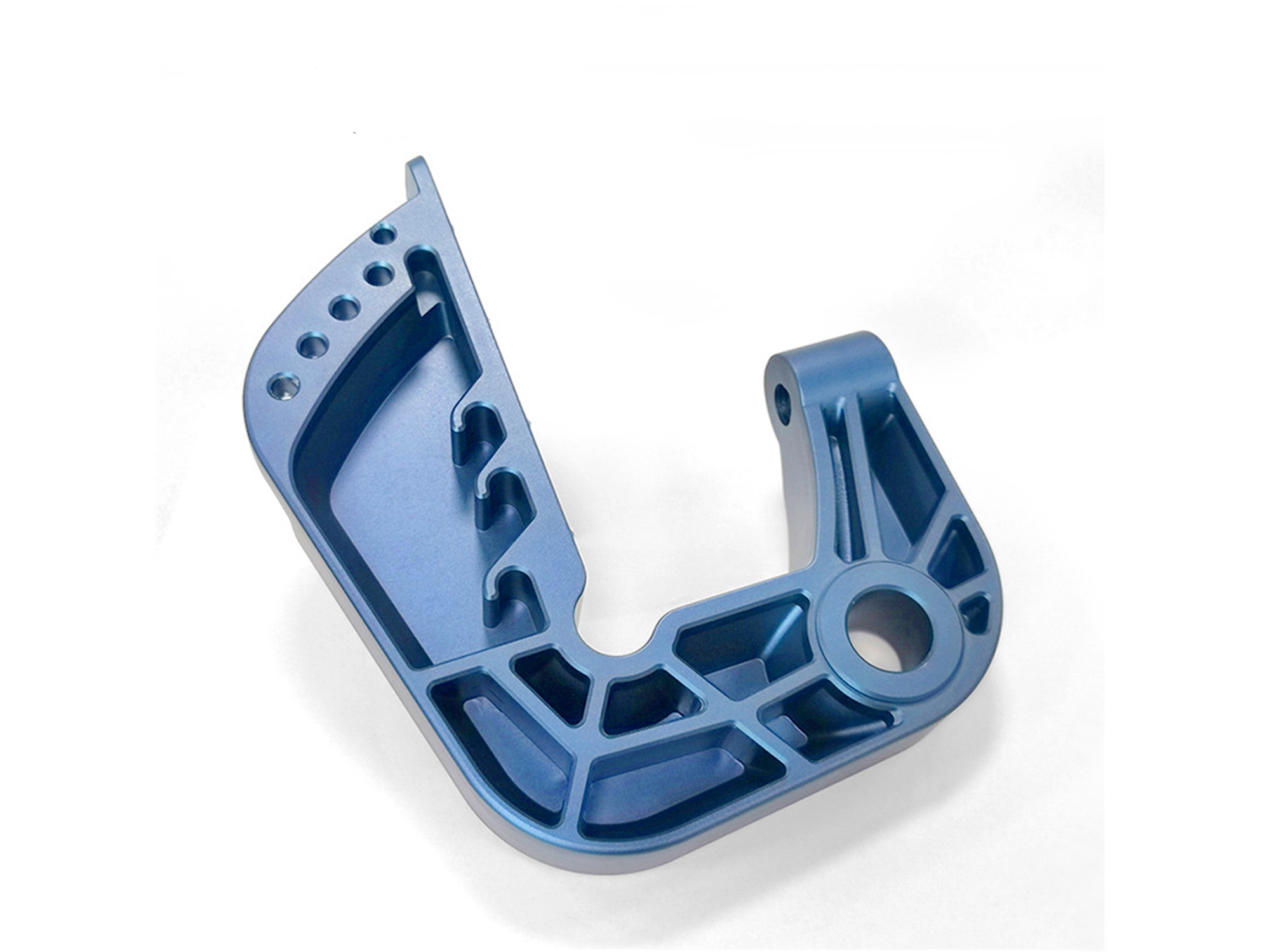

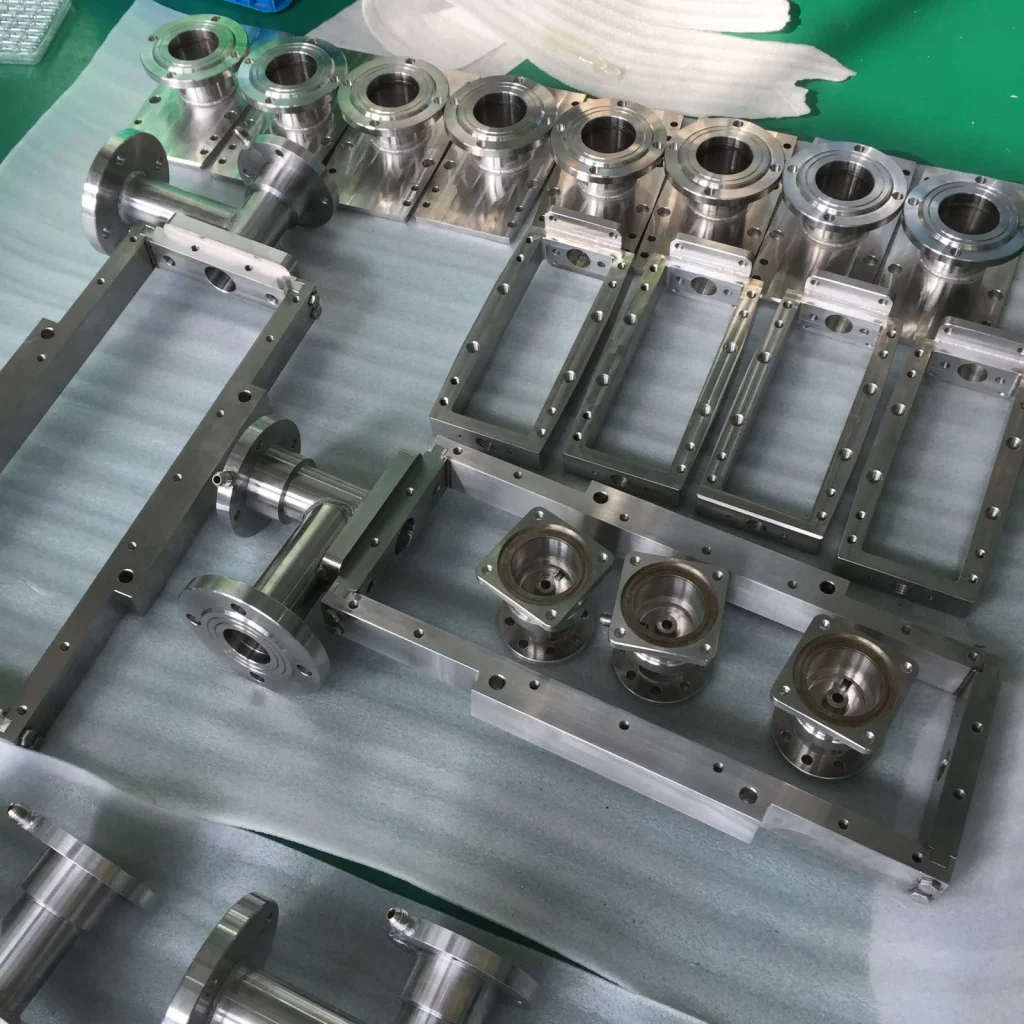

At ZE-TECH MOLD, we specialize in CNC machining and mold fabrication for high-precision robotic components, ensuring superior performance, strength, and dimensional accuracy. This article explores the materials commonly used in robot manufacturing and key machining factors that affect product quality.

1. Common Materials Used in Robot Manufacturing

Robots are made up of several subsystems — structure, motion, sensing, and control. Each part requires materials that meet specific mechanical, thermal, and weight requirements.

1.1 Aluminum Alloys

- Features: Lightweight, excellent strength-to-weight ratio, easy to machine.

- Applications: Frames, arms, housings, and brackets.

- Example Alloy: 6061-T6, 7075-T6 — used in both industrial and service robots.

- Machining Tip: Use sharp tools and optimized feeds to prevent built-up edges and maintain dimensional stability.

1.2 Stainless Steel

- Features: High strength, corrosion resistance, and durability.

- Applications: Joints, shafts, and parts exposed to wear or chemicals.

- Example Grade: 304, 316, 17-4PH.

- Machining Tip: Requires lower cutting speeds; coolant must be used to avoid heat-induced deformation.

1.3 Titanium Alloys

- Features: Excellent mechanical strength and fatigue resistance with low density.

- Applications: Lightweight high-load joints, aerospace or surgical robots.

- Machining Tip: Use rigid setups and coated carbide tools to handle titanium’s low thermal conductivity.

1.4 Engineering Plastics

- Materials: POM (Delrin), PA66, PEEK, and ABS.

- Applications: Gears, covers, insulation parts, and lightweight joints.

- Benefits: Reduce friction, noise, and weight while offering electrical insulation.

1.5 Copper and Brass

- Features: Excellent electrical and thermal conductivity.

- Applications: Connectors, sensors, and actuator components.

- Machining Tip: Control feed rate to prevent burring and maintain dimensional precision.

2. Machining Considerations for Robotic Components

The performance and reliability of a robot depend heavily on machining accuracy and surface quality.

Below are key technical factors ZE-TECH MOLD emphasizes during production:

| Machining Aspect | Key Consideration | Purpose |

|---|---|---|

| Tolerance Control | ±0.01–0.02 mm for precision assemblies | Ensures smooth joint motion and stable alignment |

| Surface Finish | Ra ≤ 0.8 µm for sliding parts | Reduces friction and improves motion efficiency |

| Tool Path Optimization | 5-axis CNC machining | Enables complex geometry and multi-angle processing |

| Thermal Stability | Proper cutting fluids and cooling strategy | Prevents warping or deformation during machining |

| Fixture Design | Customized clamping systems | Maintains accuracy and repeatability in multi-part production |

3. The Importance of Weight and Rigidity Balance

For robots — especially collaborative (cobots) and mobile platforms — weight directly affects energy efficiency and motion control.

- Using aluminum or carbon-fiber composites reduces inertia, improving dynamic response.

- High-rigidity materials such as steel or titanium are preferred for load-bearing parts to prevent vibration.

At ZE-TECH MOLD, engineers balance these two demands through multi-material integration and precision machining, ensuring every component meets functional and structural goals.

4. Post-Processing and Assembly Precision

After machining, robotic components often require surface treatments and dimensional verification:

- Anodizing & Sandblasting – for corrosion resistance and clean appearance

- Polishing & Passivation – to reduce friction in moving parts

- Coordinate Measuring Machine (CMM) inspection – ensures dimensional accuracy across assemblies

Our in-house CNC finishing and inspection capabilities allow us to deliver ready-to-assemble parts with consistent performance and minimal deviation.

5. ZE-TECH MOLD’s Expertise in Robotic Component Manufacturing

At ZE-TECH MOLD, we combine:

- 5-axis CNC machining

- Precision EDM & milling

- Rapid prototyping & mold fabrication

to meet the demanding standards of robotic component production.

Our process ensures:

- Fast delivery times for prototype and small batch runs

- High accuracy for moving and structural parts

- Strong material integrity after machining and post-treatment

Conclusion

Robot manufacturing demands not only innovation in design but also deep expertise in materials and machining processes.

By integrating knowledge of aluminum, stainless steel, titanium, and engineering plastics with state-of-the-art CNC machining, ZE-TECH MOLD provides reliable manufacturing solutions for robotic systems across various industries.