Introduction

Automation and robotics are transforming CNC machining, driving higher precision, faster cycle times, and consistent quality. As the demand for smart production surges, integrating robotics into CNC processes has become a critical differentiator for innovative manufacturers. This article explores the evolution, benefits, challenges, and future of automation and robotics in CNC machining, offering insights into how these technologies are shaping the future of manufacturing.

Why Automation Matters in CNC Machining

With the rise of Industry 4.0, automation and robotics enable manufacturers to optimize workflows, reduce costs, and stay competitive. By adopting these technologies, companies can achieve unparalleled efficiency and precision in CNC manufacturing.

The Evolution of Automation in CNC Machining

CNC machining has evolved from manual operations to fully automated, smart systems. This transformation, driven by advancements in robotics and Industry 4.0 technologies, has redefined production workflows.

| Stage | Description | Technology Used |

|---|---|---|

| Manual CNC Operation | Human operators manage material loading, monitoring, and inspection. | Basic CNC machines |

| Semi-Automation | Automated loading/unloading and tool changers reduce manual effort. | PLC systems, robotic arms |

| Smart Automation | Fully integrated robotic cells with AI-driven optimization. | Collaborative robots (cobots), IoT sensors |

Automation eliminates human error, ensures repeatability, and enables 24/7 production, significantly boosting CNC machining efficiency.

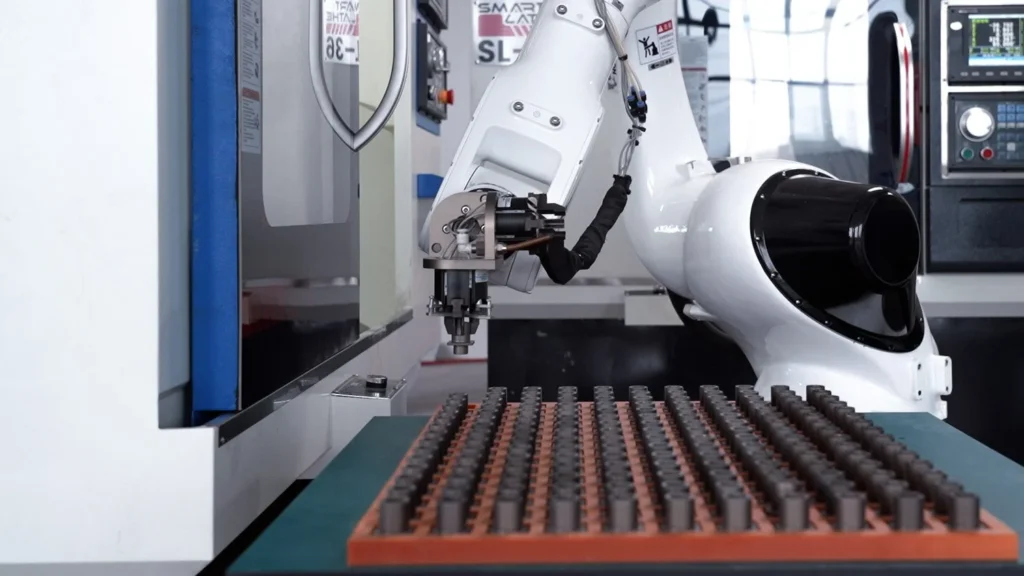

The Role of Robotics in CNC Operations

Robots are revolutionizing CNC machining by automating repetitive and hazardous tasks, including:

- Material Handling: Loading raw materials and unloading finished parts with precision.

- Tool Management: Automatic tool changing and calibration for seamless operations.

- Quality Inspection: Robots with vision systems ensure real-time quality assurance.

- Post-Processing: Polishing, deburring, or cleaning parts post-machining.

Collaborative robots (cobots) work alongside human operators, blending precision with flexibility. This hybrid approach enhances productivity while preserving the expertise of skilled CNC technicians.

Benefits of Automation in CNC Machining

Automation delivers measurable advantages over traditional manual CNC processes, making it a game-changer for manufacturers.

| Aspect | Manual CNC | Automated CNC |

|---|---|---|

| Productivity | Limited by operator shifts | 24/7 continuous operation |

| Consistency | Subject to human variation | Highly repeatable and precise |

| Labor Cost | High | Reduced with ROI in 1–2 years |

| Safety | Operator exposure to hazards | Robots handle dangerous tasks |

Automation minimizes downtime, optimizes tool paths, and reduces material waste, contributing to sustainable manufacturing and cost savings.

Challenges and Solutions in CNC Automation

While automation offers significant benefits, manufacturers face challenges during implementation. Here’s how to address them:

- High Initial Investment: Conduct ROI analysis and adopt automation in phases to manage costs effectively.

- Integration Complexity: Choose modular systems for scalability and seamless integration with existing CNC setups.

- Skilled Labor Demand: Upskill CNC technicians in robotic programming to bridge the skill gap.

Partnering with experienced automation solution providers allows manufacturers to design customized CNC robotic cells tailored to specific production goals and part requirements.

The Future of Smart CNC Production

The next frontier in CNC machining lies in integrating AI, IoT, and machine learning for fully smart manufacturing. Key advancements include:

- Predictive Maintenance: AI-driven systems predict tool wear and machine failures, reducing downtime.

- Self-Optimizing Toolpaths: Real-time adjustments to cutting parameters for maximum efficiency.

- Autonomous Robotic Scheduling: Robots prioritize tasks based on production demands.

In the near future, CNC machining will evolve beyond cutting parts—it will analyze, adapt, and improve processes in real time, setting a new standard for smart production.

Conclusion

Automation and robotics are no longer optional in CNC machining—they are the cornerstone of next-generation smart production. By embracing these technologies, manufacturers can achieve higher efficiency, unmatched precision, and a competitive edge in a digital-driven world. Start exploring CNC automation solutions today to transform your manufacturing processes and stay ahead in the industry.