Commonly Used Sheet Metal Bracket Production Guide

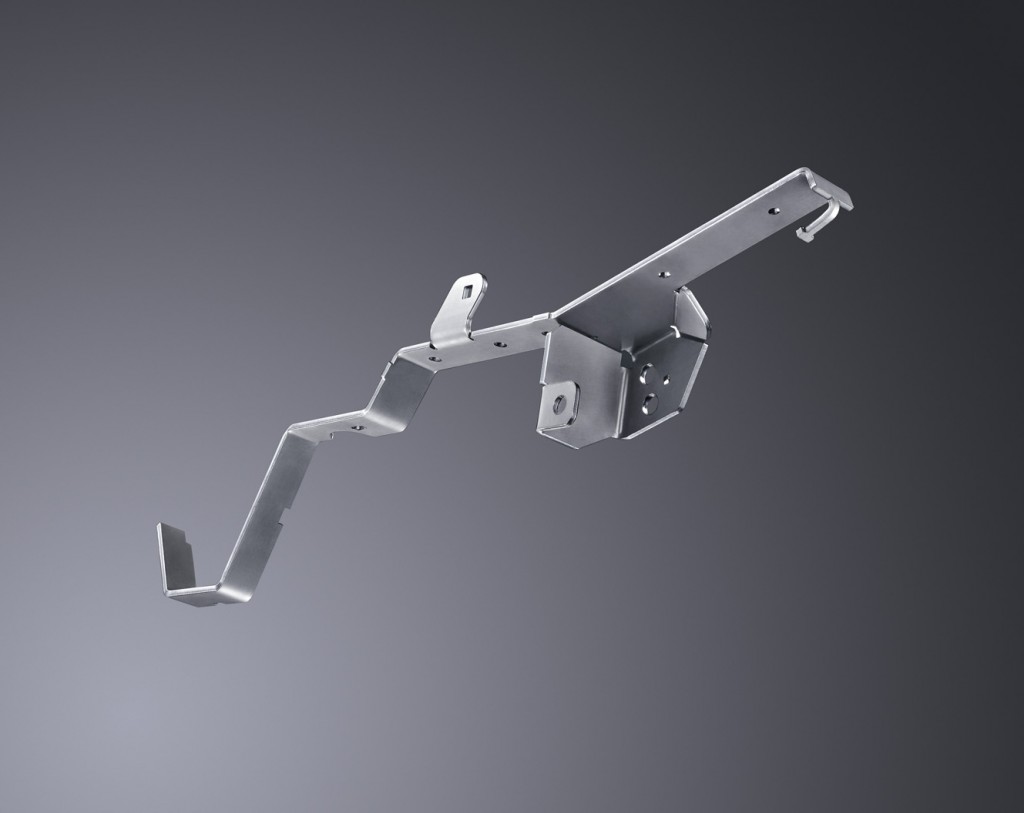

Introduction Sheet metal brackets are essential structural components across robotics, consumer electronics, automotive systems, industrial machinery, and smart devices. Their purpose is simple—support, positioning, and fixation—but their production involves precise engineering, strict tolerances, and optimized manufacturing processes.This guide explains the materials, design principles, fabrication processes, and quality control methods commonly used in sheet metal bracket […]

Commonly Used Sheet Metal Bracket Production Guide Read More »