At Ze-tech Mold, we’re experts in CNC machining, injection molding, and rapid prototyping, but we also recognize casting as a foundational manufacturing process for creating complex metal and plastic parts at scale. Whether you’re launching a new product or optimizing production, understanding casting can help you choose the right method for cost, speed, and performance. In this guide, we’ll cover what casting is, how it works, major types, and real-world applications — with insights from our 15+ years in precision manufacturing.

What Is Casting?

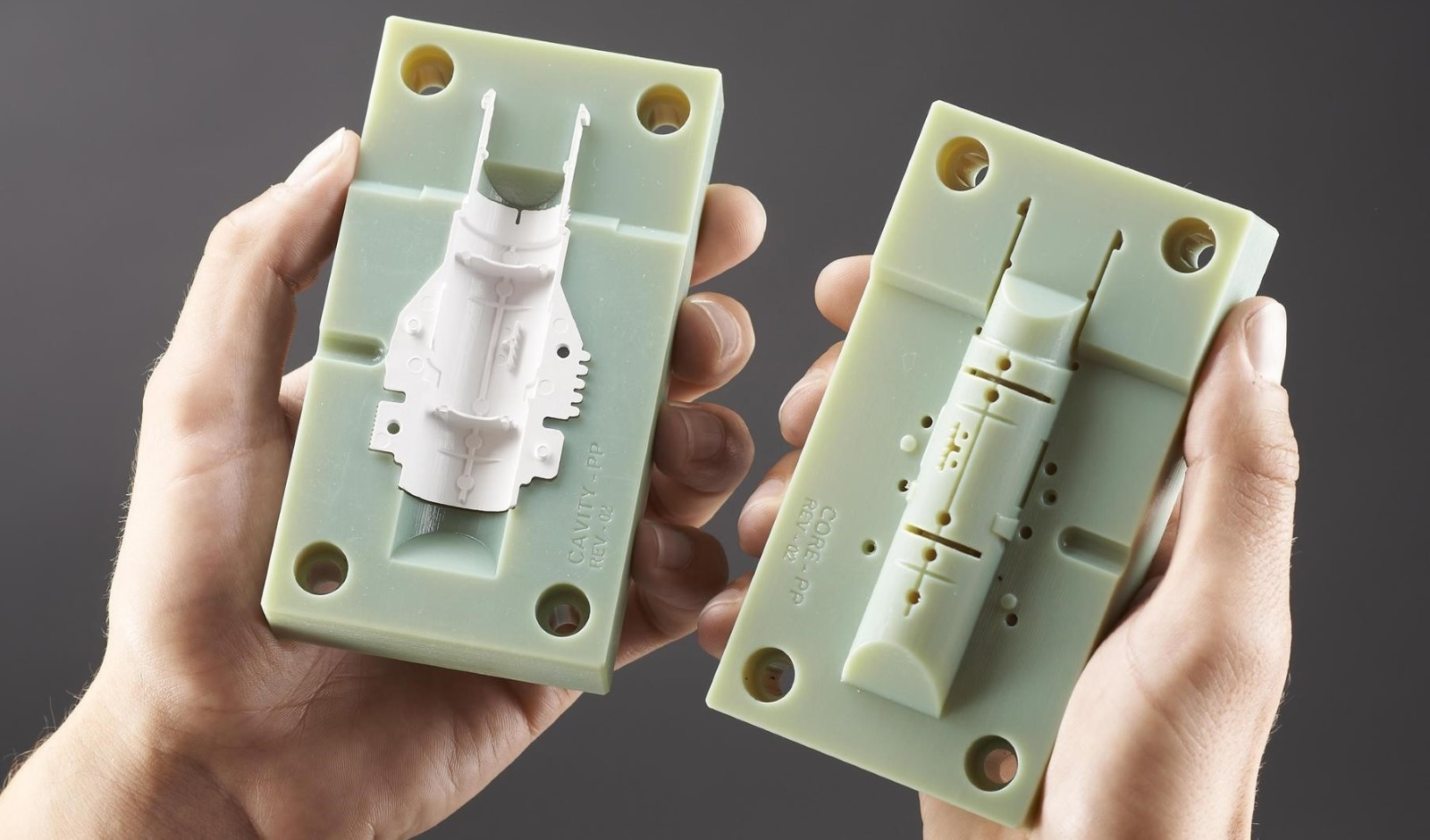

Casting is a manufacturing process where molten material (metal, plastic, or ceramic) is poured into a mold cavity shaped like the desired part. Once cooled and solidified, the part is ejected or broken out of the mold.

Why Casting?

- Produces complex geometries in one piece

- Ideal for high-volume production

- Reduces material waste and assembly steps

Unlike CNC machining (subtractive), casting is additive by mold — perfect for hollow, thin-walled, or intricate designs.

How Casting Works: Step-by-Step

- Pattern/Mold Creation – A reusable pattern or disposable mold is made.

- Material Melting – Metal or resin is heated to liquid state.

- Pouring – Molten material fills the mold under gravity or pressure.

- Cooling & Solidification – Material hardens into shape.

- Ejection & Finishing – Part is removed; gates/risers trimmed; surface finished (if needed).

Major Types of Casting

| Type | Material | Best For | Tolerances | Volume |

|---|---|---|---|---|

| Sand Casting | Aluminum, iron, brass | Large parts, low-volume prototypes | ±0.5–2 mm | 1–1,000 pcs |

| Die Casting | Aluminum, zinc, magnesium | High-precision, thin walls | ±0.05–0.1 mm | 1,000–1M+ pcs |

| Investment Casting | Steel, titanium, superalloys | Turbine blades, jewelry, medical implants | ±0.1–0.3 mm | 100–50,000 pcs |

| Permanent Mold Casting | Aluminum, magnesium | Medium runs, better surface finish | ±0.2–0.5 mm | 500–100,000 pcs |

| Centrifugal Casting | Iron, steel, copper | Pipes, rings, symmetrical parts | ±0.3–1 mm | 100–10,000 pcs |

Pro Tip: Use die casting for EV battery housings; investment casting for surgical tools.

Casting vs. CNC Machining vs. Injection Molding

| Process | Material | Complexity | Lead Time | Cost per Part |

|---|---|---|---|---|

| Casting | Metals (mainly) | High | Medium | Low (high volume) |

| CNC Machining | Metals, plastics | Very High | Fast (proto) | High (low volume) |

| Injection Molding | Thermoplastics | High | Slow (tooling) | Very Low (mass) |

Hybrid Approach: Many Ze-tech Mold clients cast a near-net-shape part, then CNC machine critical features for precision.

Industry Applications of Casting

| Industry | Common Cast Parts |

|---|---|

| Automotive | Engine blocks, gearbox housings, wheels |

| Aerospace | Turbine blades, structural brackets |

| Medical | Orthopedic implants, dental tools |

| Consumer Goods | Cookware, lighting fixtures, hardware |

| Industrial | Pump housings, valve bodies, machine bases |

Success Story: A medical device OEM used investment casting + CNC finishing at Ze-tech Mold to produce titanium bone plates with 100% biocompatibility and ±0.02mm tolerance.

Advantages & Limitations

| Pros 🔹 | Cons 🔸 |

|---|---|

| Complex shapes in one step | High initial tooling cost (die) |

| Excellent for mass production | Porosity risk in some alloys |

| Wide material compatibility | Slower for prototypes |

Ze-tech Mold: Your Casting + CNC Partner

While we specialize in CNC machining and injection molding, we partner with ISO-certified foundries to offer end-to-end casting solutions:

- Design for Casting (DFC) Analysis – Free with every quote

- Material Selection Guidance – Aluminum A356, Zinc Zamak, Stainless Steel

- Post-Casting CNC Machining – Drill, tap, mill to final tolerance

- Surface Finishing – Powder coating, anodizing, plating

- Rapid Prototyping Alternative – 3D printed sand molds for 1–10 pcs

Ready to Cast Your Next Part?

From prototype validation to mass production, casting delivers strength, complexity, and scalability. Let Ze-tech Mold guide you from concept to finished part.

📞 Contact Michelle Tang: 0086 18025337983