CNC Machining

ZE-TECH is a CNC machining company that provides CNC machining services.

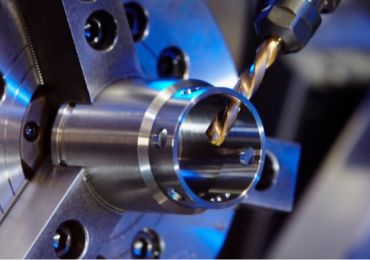

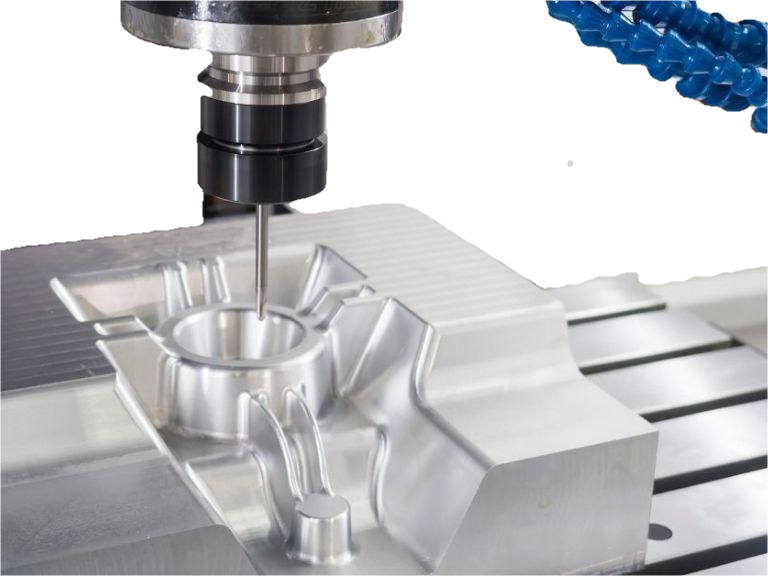

Computer Numerical Control (CNC) Machining is a precision manufacturing process that utilizes computerized controls to operate machine tools such as lathes, mills, routers, and grinders. By converting digital design files (e.g., CAD models) into numerical instructions, CNC systems execute complex cutting, shaping, and finishing operations with micron-level accuracy, ensuring repeatability and minimal human error.

Which service would you like?

Here are six CNC Machining services for you to choose from.

CNC turning is ideal for machining deep holes, machined threads, and all types of cylindrical shapes with excellent surface finish, producing high-precision cylindrical parts, usually cones, disks, or combinations of shapes. It has the characteristics of high precision of processed parts, a short production cycle, and high similarity.

CNC milling is an excellent solution for rapid prototyping and end-use components, allowing your design team to realistically simulate the form, performance, and material properties of the final product and test components for suitability and manufacturability to prove and refine their designs. CNC milling can create complex prismatic shapes and flat surfaces for a variety of commercial and industrial products.

Rapid prototyping is the best solution when you need to quickly manufacture high-quality plastic injection molds or die-casting tools. It is a “fast food” part machining service for small batch production or rapid prototyping.

CNC surface grinding is a common machining method in precision CNC machining services, and surface grinding is the best CNC machining method if your part requires a very flat surface. Special grinding wheels pass over the surface of the workpiece under the CNC program of the digital motor to provide the final surface evenness.

Alternative processing solutions for 3D printing materials. CNC prototyping plastic processing technology is generally used to make conceptual models of accurate functions, or plastic parts, which will come in handy before product development. Compared with other material processing, the price of plastic processing will be relatively affordable, and it can also meet the needs of small batch CNC processing and manufacturing.

Swiss CNC machining is currently the most suitable process for small precision parts in CNC lathes, capable of producing parts with tight tolerances. In this machining, oil is used as a coolant, originally developed for machining machines in the Swiss watchmaking industry. If you need to do precision small parts machining, then Swiss CNC machining is the best choice for you.

Our advantages of 5 Axis Maching

- Top-quality 5-axis machines

Our machinery includes HAAS and JingDiao 5-axis

CNC machines, with an on-site

inspection system to achieve super-tight tolerances

- Experience and expertise

With a decade of experience in the machining

business, and with comprehensive

knowledge of material properties, we know how to

handle even the most complex

parts — no matter the medium.

- Industry compatibility

From automotive parts to high-tech electronic

products, we’ve worked with

companies all across the manufacturing spectrum.

Process Flow of CNC Machined Parts

Send Drawings

We offer custom CNC machining services according to your design/ drawings, in order to protect customer’s privacy, we will sign the NDA with our customers, all our suppliers have to sign NDA as well.

Material Inspection

All materials will be inspected with professional equipment to ensure the material quality is as good as expected.

Programing

Our experienced engineering team will program your design drawings that can be CNC machined through professional software, and find out the deficiencies in time.

CNC Machining

CNC machining is generally divided into roughing and finishing. Roughing cuts a large amount of raw materials to process the approximate outline of the product. Finishing cuts a tiny amount of material each time to ensure that the error of each dimension of the product is within the allowable range, our tolerance accuracy can reach 0.005mm.

Inspection

The processed products need to undergo a comprehensive inspection to ensure that the product dimensional deviation is within the allowable range of the design drawings. And the surface of the product will be carefully polished to remove burrs. If you have special surface treatment requirements, we have our own surface treatment workshop to provide you with anodizing, powder……

Packaging

After the QC of all products is completed, they will be packaged. The inner packaging is made of anti-collision foam and filled with gaps, so as to avoid damage to the product due to shaking and impact during transportation. The outside is packed in very durable carton boxes for secondary protection.

Online CNC Machining Services

CNC machining, also known as numerical control machining, refers to the computer numerical control system issuing instructions to make tools (such as drills, lathes, milling machines, grinding machines, milling machines, 3D printers, etc.) perform various movements that meet the processing requirements.

This is a subtractive manufacturing process. Its working principle is to use a computer-controlled machine tool to remove the material layer on the raw material (alias: blank) to form a specially designed part handicraft. Generally refers to the process of forming parts from prototype materials on CNC machine tools.

Unlike additive manufacturing processes such as 3D printing and formable manufacturing processes such as liquid injection molding. The process is suitable for a wide variety of materials such as common metals, glass, plastics, wood, composites, and foams.

CNC machine tools are machine tools controlled by computers, and the computers used to control machine tools are collectively referred to as CNC systems. The movement and auxiliary actions of CNC machine tools are controlled by commands issued by the CNC system. Our commonly used CNC lathes, such as CNC grinding machines, lathes, milling machines, etc., all belong to CNC machine tools…

Features of CNC machining

The biggest feature of online machining is the use of perforated belts (or magnetic tapes) to control machine tools for automatic machining. It is the key way to solve the difficulties of ordinary machining methods. The ability to perform high-precision machining of a wide variety of metal parts with complex contours makes it a popular choice for applications in many industries, including aerospace, automotive, medical devices, and more. Common such as aircraft parts, automobile engine parts, bicycle parts, and so on.

CNC Machining Application Scenes

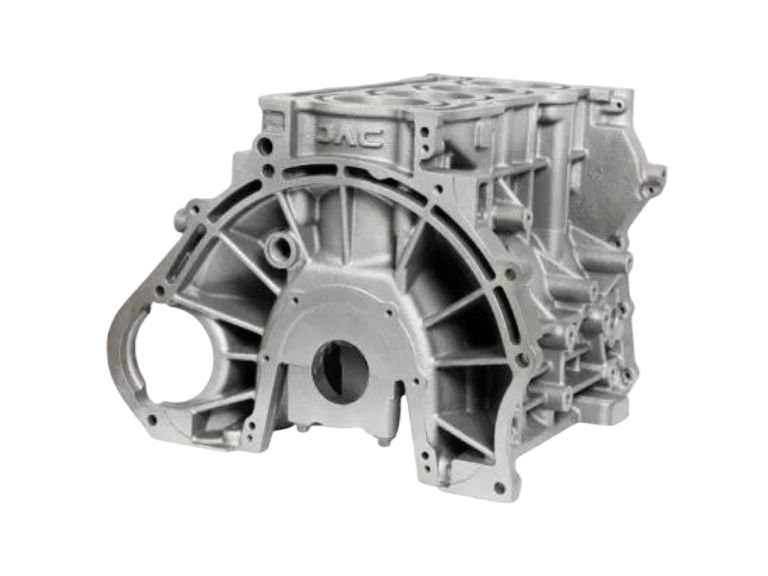

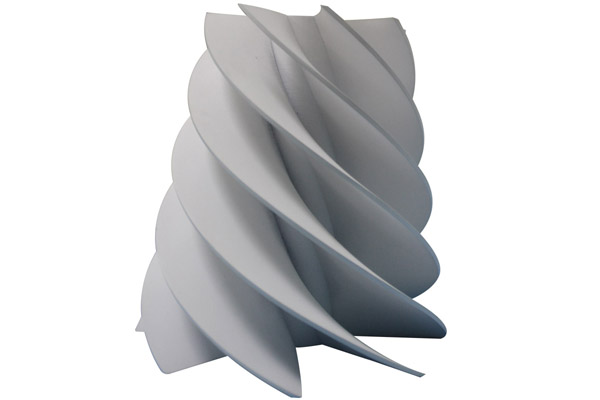

CNC machining is common in aircraft component manufacturing. In addition, it is used in defense production. For example; weapons, turbines, wing assemblies, engine parts, cabin parts, ammunition, and other similar items.

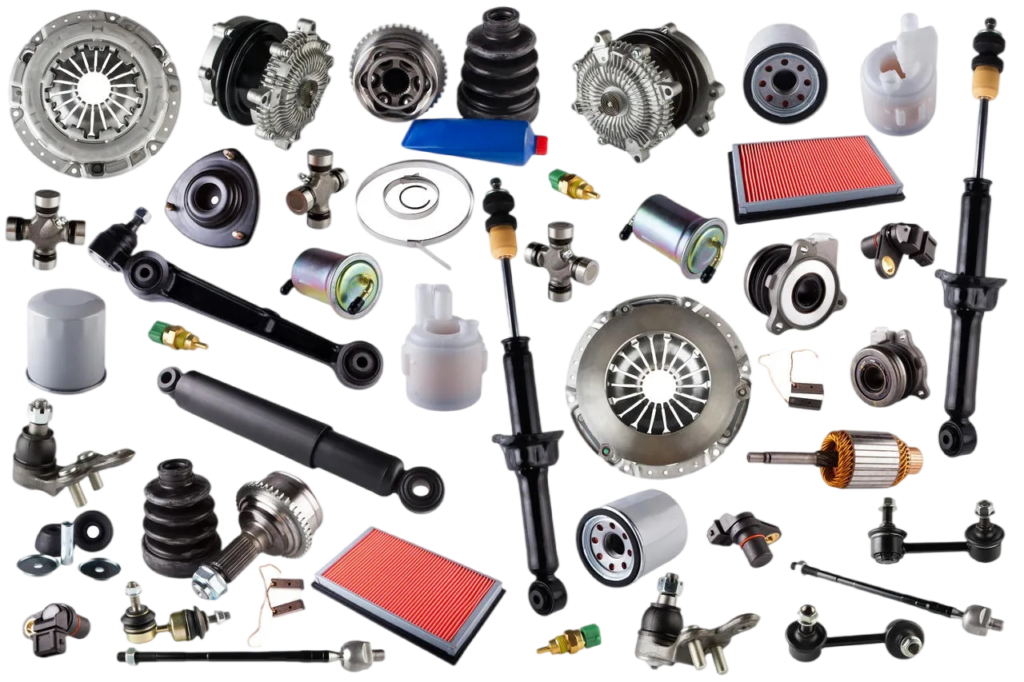

CNC machine tools produce various car and truck parts. Some examples include engine components, transmission components, suspension components,connecting rods, crankshafts, bushings, valve cores, valve guide rods, transmission shafts, brake discs, cylinder heads, hubs, engine internal parts, etc..

CNC machining is also important for the manufacture of parts and equipment in the medical field, such as surgical equipment, orthopedics, dental equipment, surgical instruments, and other precision components.

CNC machines can produce a wide variety of consumer goods. Such as circuit boards, computer casings, chassis, and other common household items.

CNC machining is commonly used to produce components for a variety of machinery and equipment. Some examples include pumps, valves, and gears.

CNC machining is mostly used to produce prototypes and test parts for R&D purposes. Compared with traditional production methods, the production speed is at least 15 times that of traditional processing methods. It can reduce the cost of product development to a certain extent, shorten the time to market, and occupy the market earlier than competitors.

Intricate jewelry requires the precision and repeatability that only CNC machining can ensure. The Swiss CNC machining services mentioned above are dedicated to high-precision, complex-shaped, multi-variety, and small-batch production. It can meet the growing demand of the market, and the production speed is fast, not as slow as handmade. That’s why it’s so popular in this field.

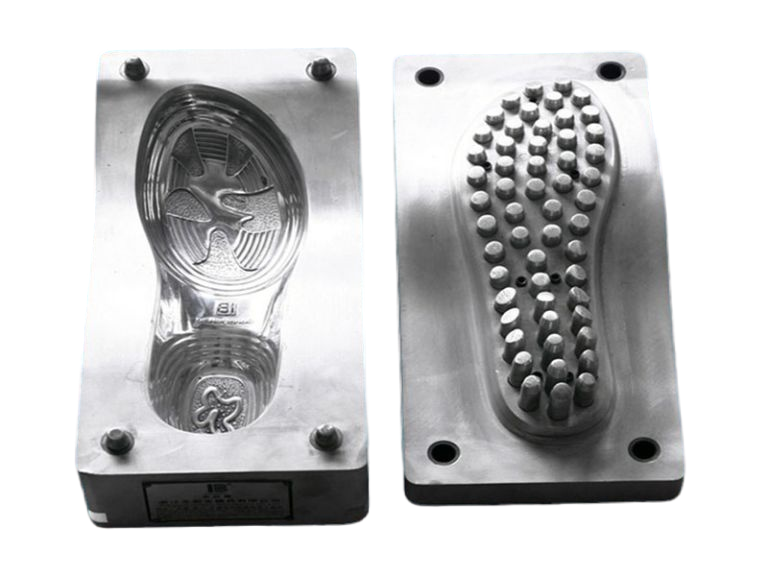

CNC machining of molds for the production of plastic and metal products. Compared with ordinary mechanical processing technology, the precision of molds produced by CNC processing technology is higher, because CNC processing has diversified characteristics, and a variety of different processing schemes can be formulated for the same processing task.

CNC machining is common in the production of metal components in a variety of industries including construction, agriculture, and mining.

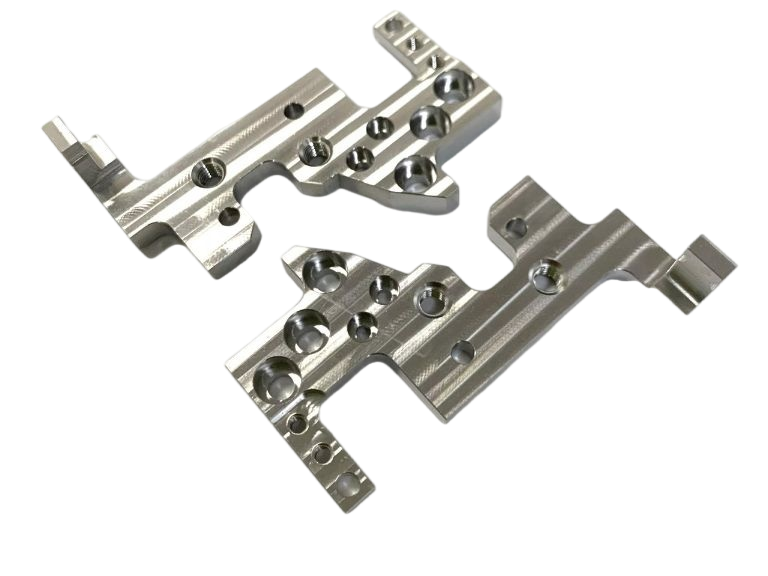

CNC products Cases

ZE-TECH CNC Machining Service Frequently Asked Questions

We know that you may have some questions about CNC machining services. We have compiled the answers to the following common CNC machining project questions, hoping to help you.

Is CNC machining hard?

ZE-TECH is a large CNC machining company with multi-axis CNC machining machines, which can do 3-axis CNC machining, 4-axis CNC machining, and 5-axis CNC machining, so for us, CNC machining is not difficult.

How much is your CNC machining service cost?

The cost of CNC machining items is not fixed, because it depends on the CNC machining items, such as design and tolerance. Materials used in the project and processing time can also affect this pricing. For example, the pricing of aerospace CNC machining projects differs from that of ordinary automotive CNC machining products.

What is the tolerance of the machined parts?

For metal CNC machining, the tolerance of our machined parts is about ±0.008mm. Note that the higher the tolerance required, the higher the cost.

Do you accept cheap CNC machining projects?

Of course, we have no minimum order quantity. As long as you have needs for CNC machining parts,ZE-TECH will provide you with corresponding CNC machining service solutions, and you don’t need to worry about expensive CNC machining costs.

What is your CNC machining capacity?

We can provide tens of thousands of different orders for CNC machining projects every month, whether it is small batch CNC machining or high precision CNC machining. We have multiple CNC machine tools and many experienced technical experts to provide you with technical support.

What is your CNC service process like?

There are 3 steps in total.

1. First upload your CNC processing drawings (CAD files), our professional engineers analyze the images, confirm the specifications, choose the delivery time that suits your schedule, and then give you a quotation.

2. Production, when you confirm the order, we will start production immediately.

3. Quality inspection and control, when the parts are produced, we will carry out the quality inspection to ensure that your parts are manufactured according to our standards before delivery.