Introduction

In the medical industry, product safety and reliability are non-negotiable. From surgical instruments to orthopedic implants, every medical device must meet strict dimensional accuracy, biocompatibility, and regulatory standards. CNC machining has become a cornerstone of medical device manufacturing due to its ability to deliver high precision, repeatability, and compatibility with advanced materials. However, success in this sector requires more than machining skill—it demands compliance with rigorous industry regulations.

Why CNC Machining is Essential in the Medical Industry

CNC machining offers distinct advantages that align with the requirements of the healthcare sector:

- Unparalleled Precision – Tolerances as tight as ±0.002 mm are often required in implants and surgical tools.

- Material Versatility – CNC machining supports biocompatible metals (titanium, stainless steel) and high-performance plastics (PEEK, Ultem).

- Repeatability – Ensures that every part in a batch meets the same exacting standards.

- Surface Quality – Smooth finishes reduce bacterial adhesion and improve patient safety.

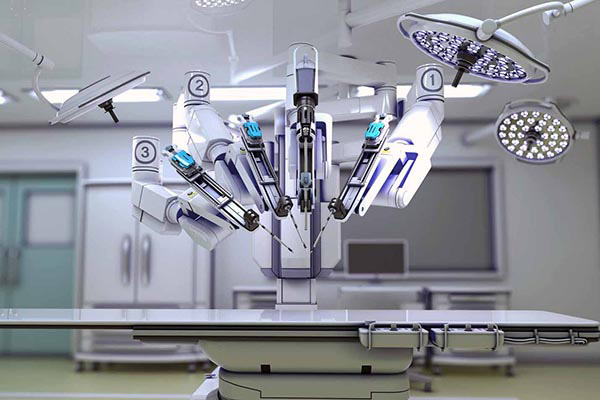

Common CNC-Machined Medical Devices

- Orthopedic implants – hip joints, knee replacements, spinal fixation devices

- Surgical instruments – forceps, clamps, scalpels

- Dental tools and implants – crowns, abutments, orthodontic brackets

- Medical housings – for imaging equipment, diagnostic tools, and wearable medical devices

Regulatory Compliance in CNC Medical Manufacturing

Manufacturers of medical devices must operate within a strict regulatory framework. The following standards are most relevant:

- ISO 13485 – Specifies quality management systems for medical device production.

- FDA 21 CFR Part 11 & 820 – U.S. FDA regulations for quality systems and electronic records.

- EU MDR (Medical Device Regulation) – Governs medical devices in the European Union.

- Biocompatibility Testing (ISO 10993) – Ensures materials are safe for human contact.

- Traceability – Every component must have documentation linking it back to raw materials and production batches.

Materials for CNC-Machined Medical Devices

| Material | Key Properties | Typical Applications | Regulatory Considerations |

|---|---|---|---|

| Titanium (Ti-6Al-4V) | Biocompatible, lightweight, corrosion resistant | Implants, bone screws, dental abutments | Widely approved by FDA and ISO 10993 |

| Stainless Steel (316L) | High strength, corrosion resistant | Surgical instruments, orthopedic tools | Must meet ASTM F138/F139 |

| PEEK (Polyetheretherketone) | Lightweight, radiolucent, biocompatible | Spinal cages, dental implants | ISO 10993 tested, FDA-approved |

| Cobalt-Chromium Alloys | Wear resistance, strength | Joint replacements, dental prosthetics | Requires extensive biocompatibility testing |

| Aluminum Alloys | Lightweight, machinable | Medical housings, diagnostic equipment | Not for implants, but suitable for external devices |

Challenges and Best Practices

- Maintaining Ultra-Tight Tolerances – Requires advanced 5-axis CNC machines and in-process metrology.

- Surface Finishing – Polishing and passivation to achieve smooth, contamination-free surfaces.

- Cleanroom Manufacturing – Especially critical for implants and sterile instruments.

- Traceability Systems – Digital records for each component to meet FDA and ISO requirements.

- Validation and Testing – Dimensional inspection, fatigue testing, and biocompatibility validation before approval.

Conclusion

CNC machining for medical devices is about more than producing precise parts—it’s about ensuring patient safety and regulatory compliance. By combining advanced machining technology with robust quality management systems, manufacturers can deliver reliable, high-performance medical devices that meet international standards.

At Ze-tech Mold, we specialize in precision CNC machining with full regulatory compliance, offering end-to-end solutions from prototyping to large-scale production for the medical sector.