In precision manufacturing, CNC machining tolerances define the difference between a component that functions seamlessly and one that fails in real-world applications. From aerospace engines to medical implants, tolerances determine not only fit and performance but also cost efficiency and long-term reliability.

At Ze-tech Mold, we understand that tolerances are more than just numbers on a technical drawing—they are the foundation of product quality. This article explores what CNC machining tolerances are, why they matter, the standards that guide them, and how to balance performance with cost.

What Are CNC Machining Tolerances?

A tolerance specifies the permissible deviation from a target dimension. No machining process can achieve absolute perfection, and tolerances establish the acceptable range within which a part is considered accurate.

📊 CNC Machining Tolerances Chart (Reference)

| Tolerance Level | Range (Typical) | Applications |

|---|---|---|

| Tight Tolerances | ±0.01 mm or better | Aerospace, medical, optical devices |

| Standard Tolerances | ±0.05 mm – ±0.1 mm | Automotive, industrial machinery |

| General Tolerances | ±0.1 mm – ±0.5 mm | Prototypes, rough machining, non-critical parts |

Many industries follow ISO 2768 for general tolerances and GD&T (Geometric Dimensioning & Tolerancing) for defining form, orientation, and positional accuracy.

Why CNC Machining Tolerances Matter

- Fit and Assembly

Precision ensures parts integrate smoothly. For example, shafts, bearings, and housings require tolerances within microns to function without excessive wear. - Performance and Safety

In sectors like aerospace and healthcare, even a 0.02 mm deviation can compromise safety. Tight tolerances ensure reliability in critical environments. - Cost Efficiency

While tighter tolerances improve accuracy, they also increase machining time, tool wear, and inspection requirements. Choosing the right tolerance level is a balance between functionality and budget. - Compliance with Global Standards

Using ISO and GD&T standards allows parts manufactured across different facilities worldwide to remain fully interchangeable.

Factors Influencing Machining Tolerances

- Material Properties → Metals such as aluminum and steel allow for tighter tolerances than plastics, which expand or deform.

- Machining Process → Rough machining achieves looser tolerances, while finishing operations (grinding, honing, polishing) deliver high accuracy.

- Tool Wear → Dull tools create dimensional drift over time, making preventive maintenance essential.

- Thermal Expansion → Temperature fluctuations during machining or inspection can alter measurements.

Best Practices for Achieving Optimal Tolerances

- Differentiate Critical vs. Non-Critical Dimensions → Tight tolerances should only apply where they add functional value.

- Use GD&T for Clear Communication → Prevents misinterpretation between designers, engineers, and machinists.

- Apply Multi-Step Machining → Use roughing for material removal and finishing for precision.

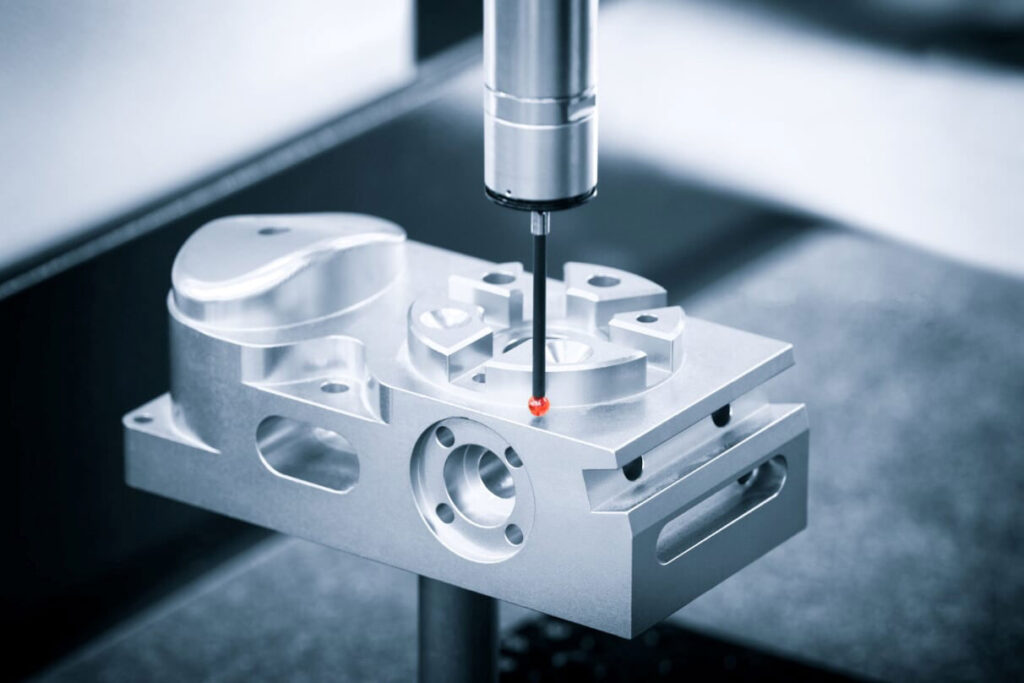

- Implement Rigorous Quality Control → CMM (Coordinate Measuring Machine) inspections, surface roughness testing, and first-article inspections ensure compliance.

- Collaborate with an Experienced Partner → Manufacturers with advanced equipment and engineering support can optimize both accuracy and cost.

Ze-tech Mold’s Expertise in CNC Machining Tolerances

At Ze-tech Mold, we specialize in:

- Achieving tolerances as tight as ±0.01 mm across metals and plastics

- Utilizing advanced 5-axis CNC machining centers and CMM inspection systems

- Offering both prototype machining and mass production solutions

- Supporting industries including aerospace, automotive, medical devices, and electronics

With expertise in CNC machining, rapid injection molding, sheet metal fabrication, 3D printing prototypes, and surface finishing, we ensure every project meets the highest standards of accuracy and reliability.

Conclusion

CNC machining tolerances are not simply technical specifications—they are the language of precision. By defining acceptable deviation, tolerances impact fit, safety, cost, and global compatibility.

The right strategy balances design requirements with manufacturability, ensuring that each part performs as intended while controlling production costs.

At Ze-tech Mold, our commitment to tight tolerance machining and quality assurance ensures your components meet the strictest industry demands. Whether for prototypes or large-scale production, we deliver precision, reliability, and cost efficiency every time.