Introduction

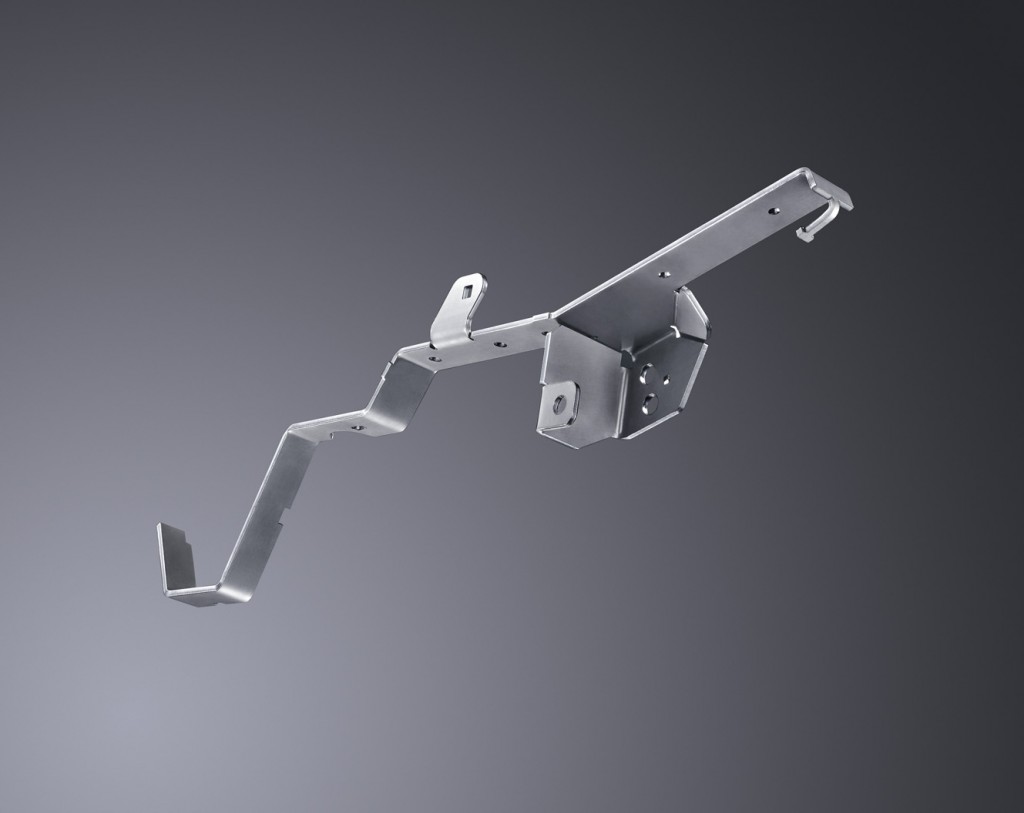

Sheet metal brackets are essential structural components across robotics, consumer electronics, automotive systems, industrial machinery, and smart devices. Their purpose is simple—support, positioning, and fixation—but their production involves precise engineering, strict tolerances, and optimized manufacturing processes.

This guide explains the materials, design principles, fabrication processes, and quality control methods commonly used in sheet metal bracket manufacturing.

1. Common Materials for Sheet Metal Brackets

| Material | Features | Application Scenarios |

|---|---|---|

| SPCC (Cold-Rolled Steel) | Smooth surface, easy stamping, low cost | Electronics housing, industrial brackets |

| Stainless Steel (SS304 / SS316) | Corrosion resistance, strength, good durability | Outdoor brackets, medical devices |

| Aluminum (AL5052 / AL6061) | Lightweight, corrosion resistance, easy to bend | Robotics, drones, lightweight equipment |

| Galvanized Steel (SGCC) | Anti-rust coating, economical | Electrical cabinets, mounting brackets |

| Copper / Brass | Conductive, heat-resistant | Electrical brackets, heat dissipation components |

Material Selection Tips

- For outdoor or corrosive environments → Use stainless steel (304/316)

- For robotics or lightweight structures → Use aluminum 5052/6061

- For mass production & low cost → SPCC or galvanized steel

2. Key Design Considerations

2.1 Thickness & Load Requirements

- Most brackets use 1.0–3.0 mm sheet thickness.

- Heavy-duty industrial brackets may require ≥4 mm sheets or reinforced ribs.

2.2 Structural Optimization

- Add bending ribs to improve rigidity.

- Avoid 90° sharp corners; use R2–R4 for stable bending.

- Ensure hole-to-edge distance ≥ 1.5 × sheet thickness to prevent tearing.

2.3 Assembly & Mounting

- Provide enough space for screws, rivets, or inserts.

- Use slot holes when adjustable positioning is needed.

- For robotics, ensure tolerance chains match motor/gearbox interface requirements.

3. Sheet Metal Bracket Production Process

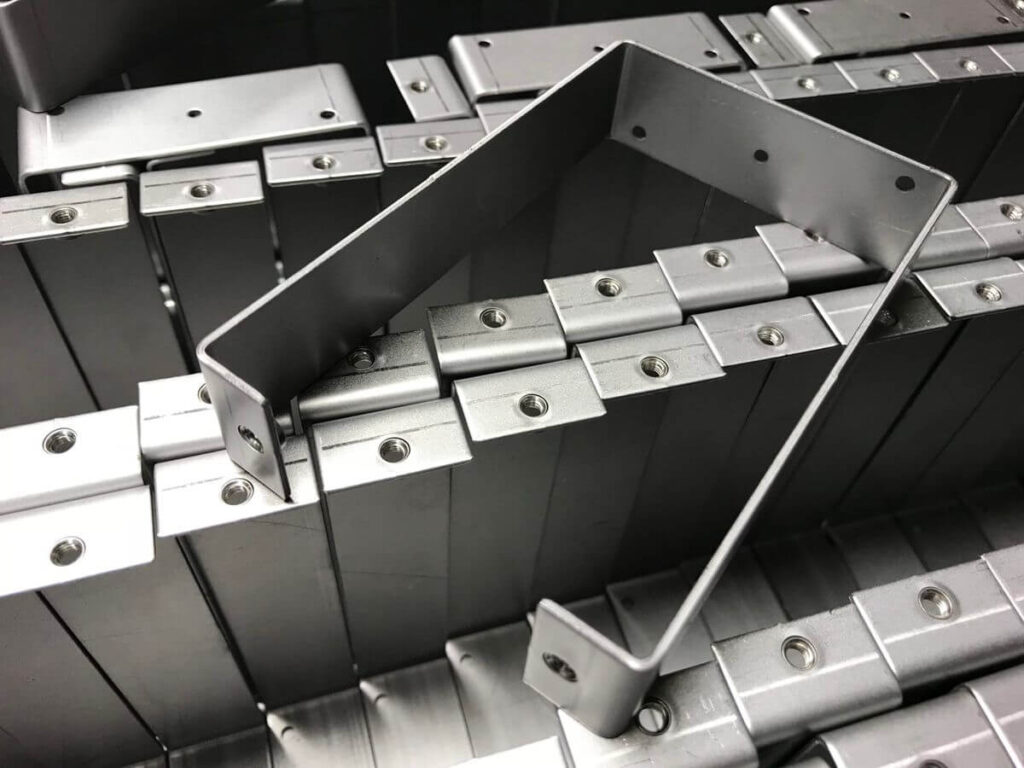

3.1 Laser Cutting or CNC Punching

- Laser cutting applies to small batches or complex shapes.

- CNC turret punching is efficient for large batches and repeated patterns.

- Tolerance typically: ±0.1–0.15 mm

3.2 Bending

- Performed using a CNC press brake.

- Bend angle tolerance: ±1°

- Important: consider bend compensation based on material and thickness.

3.3 Welding (Optional)

- MIG/TIG welding for stainless steel or steel brackets.

- Spot welding for thin-sheet assemblies.

- Post-processing may include polishing weld seams.

3.4 Surface Finishing

Common finishes include:

| Finish Type | Benefits |

|---|---|

| Powder coating | Durability, color options, corrosion protection |

| Anodizing (Aluminum) | Hard surface, anti-corrosion, aesthetic |

| Electroplating / Zinc plating | Low cost, anti-rust |

| Brushing | Aesthetic texture |

4. Quality Control Checklist

| QC Item | Standard |

|---|---|

| Dimensions | Check width, height, hole diameters, ±0.1 mm |

| Flatness | Warpage < 0.5 mm |

| Bend Angle | ±1° |

| Surface Treatment | Uniform coating, no peeling |

| Load Test | Confirm bracket rigidity meets specification |

5. Applications of Sheet Metal Brackets

- Robotics:sensor mounts, motor brackets, structural support plates

- Automotive:mounting brackets, cable brackets

- Electronics:PCB brackets, internal module mounts

- Industrial machinery:machine frame support, fixture components

- Building hardware:HVAC, cabinets, shelving systems

Conclusion

Producing sheet metal brackets involves well-planned material selection, optimized design parameters, precision manufacturing steps, and strict quality control. Whether the bracket is for robotics, industrial equipment, or consumer products, manufacturers must balance strength, weight, tolerances, and cost-effectiveness.

A reliable sheet metal production process ensures stable performance and long-term durability of the end product.