Introduction

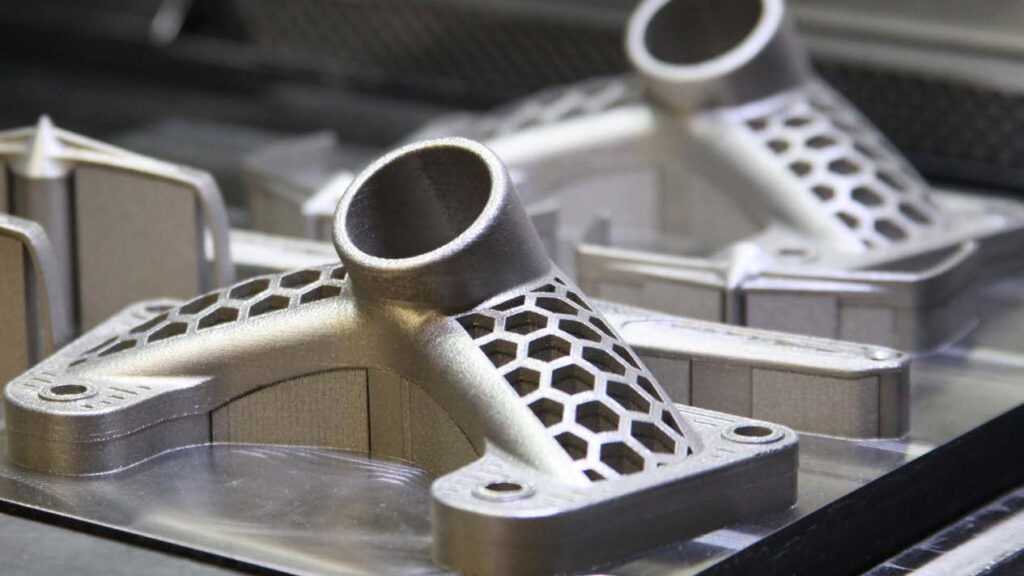

The world of manufacturing is evolving rapidly, and metal 3D printing has become a game-changer in this transformation. Among various metal additive manufacturing technologies, Direct Metal Laser Sintering (DMLS) stands out for its ability to produce complex, high-precision components directly from digital models.

At ZE-TECH MOLD, we combine DMLS technology with advanced CNC machining and mold manufacturing, offering our clients efficient solutions for prototype development, low-volume production, and complex metal parts that conventional methods struggle to achieve.

What Is DMLS?

DMLS (Direct Metal Laser Sintering) is an additive manufacturing process that uses a high-powered laser to fuse fine metal powder layer by layer, forming solid metal parts directly from a CAD model.

Unlike traditional subtractive processes such as CNC machining, DMLS adds material instead of removing it, enabling the creation of intricate geometries, lightweight lattice structures, and internal channels impossible to mill or cast.

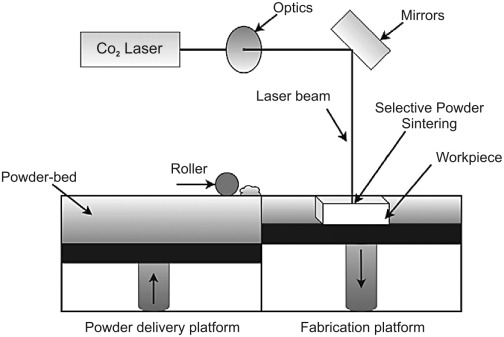

How the DMLS Process Works

- 3D Model Preparation

A CAD design is sliced into ultra-thin digital layers. Each layer guides the laser path during the build. - Powder Bed Fusion

A thin layer of metal powder (e.g., aluminum, titanium, stainless steel, Inconel) is spread over the build platform. - Laser Sintering

A high-energy laser selectively melts the powder based on the sliced model data. Once fused, it forms a solid cross-section. - Layer Repetition

The build platform lowers slightly, and a new powder layer is spread. The process repeats until the entire part is complete. - Post-Processing

After printing, parts often undergo heat treatment, CNC finishing, or surface polishing to enhance strength and appearance.

Materials Used in DMLS

DMLS supports a wide range of engineering-grade metal powders, including:

- Aluminum alloys (AlSi10Mg) – lightweight and durable

- Stainless steel (316L, 17-4PH) – corrosion-resistant and strong

- Titanium (Ti6Al4V) – biocompatible and high strength-to-weight ratio

- Inconel 625 / 718 – heat-resistant for aerospace applications

- Tool steels (H13, maraging steel) – ideal for molds and dies

Advantages of DMLS Technology

✅ Design Freedom – Create complex geometries, internal channels, and organic shapes.

✅ Material Efficiency – Minimal waste compared to subtractive machining.

✅ Fast Prototyping – Rapidly test and iterate designs without costly tooling.

✅ High Strength & Density – DMLS parts often match or exceed wrought material properties.

✅ Customization – Perfect for one-off or low-volume production runs.

Limitations to Consider

While powerful, DMLS does have some constraints:

- Higher equipment cost compared to traditional machines

- Surface finish may require post-processing for precision or aesthetic use

- Build size limitations depending on machine capacity

That’s why ZE-TECH MOLD often combines DMLS with CNC finishing — ensuring tight tolerances and a smooth, production-ready surface.

DMLS vs CNC Machining

| Aspect | DMLS | CNC Machining |

|---|---|---|

| Material Usage | Additive (less waste) | Subtractive (more waste) |

| Geometry | Excellent for complex parts | Limited by tool access |

| Speed | Faster for small batches | Faster for mass production |

| Surface Finish | Requires post-processing | High precision directly |

| Cost | High initial setup | Lower entry cost |

➡️ Best Practice: Many manufacturers integrate both — DMLS for complex inner geometries, CNC for precision finishing — just like ZE-TECH MOLD does for mold inserts and prototypes.

Industrial Applications of DMLS

DMLS is revolutionizing industries such as:

- Aerospace – lightweight structural components

- Automotive – performance engine parts and prototypes

- Medical – custom implants and surgical tools

- Tooling – conformal cooling channels in molds

- Electronics – heat sinks and precision connectors

At ZE-TECH MOLD, we apply DMLS in mold inserts, precision tooling, and prototype validation, delivering faster lead times and better performance.

Why Choose ZE-TECH MOLD

With years of experience in CNC machining, mold fabrication, and additive manufacturing, ZE-TECH MOLD provides complete solutions — from design to finished product.

Our hybrid production approach ensures:

- Consistent quality control

- Short lead times

- Cost-effective production

- Tailored engineering support for every client

Conclusion

Metal 3D printing through DMLS technology is no longer just a trend — it’s a critical tool in modern precision manufacturing.

By integrating DMLS with CNC machining, ZE-TECH MOLD helps clients achieve the perfect balance of innovation, accuracy, and efficiency in every project.