Introduction

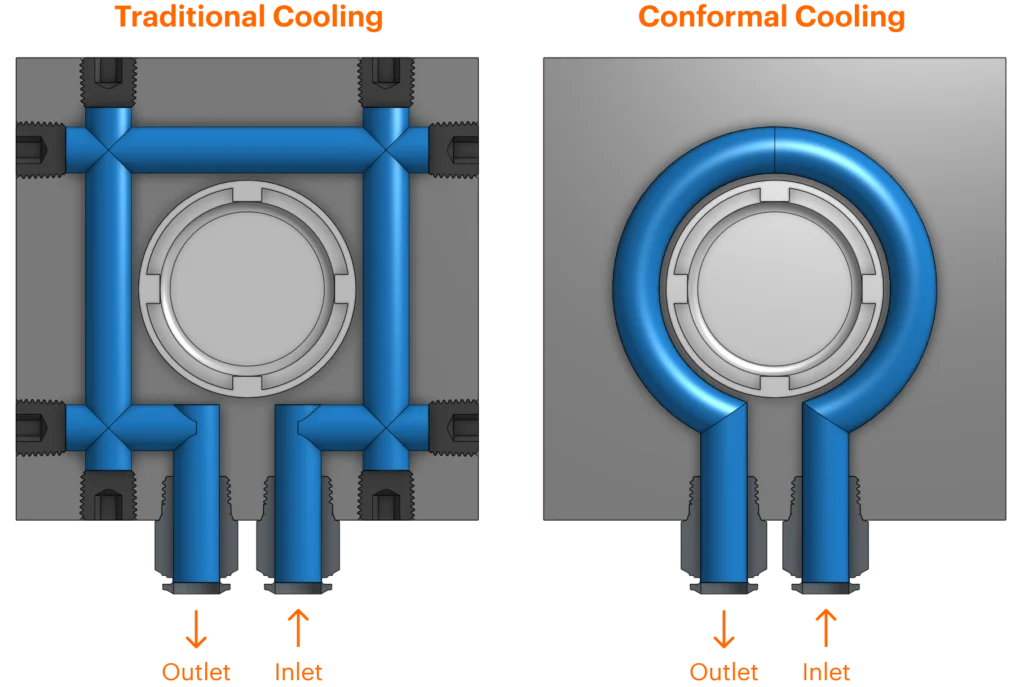

In injection molding, cooling is the longest phase of the cycle—often accounting for 60–70% of the total cycle time. Traditional straight-drilled cooling channels have limitations in reaching complex geometries, leading to uneven cooling, warpage, and longer cycle times.

Conformal cooling, enabled by additive manufacturing (AM) and advanced tooling methods, addresses these challenges by designing cooling channels that follow the contour of the molded part. This innovation allows for faster cycles, improved part quality, and reduced manufacturing costs.

What Is Conformal Cooling?

Conformal cooling refers to cooling channels that match the geometry of the part rather than following straight lines. Unlike conventional cooling systems, conformal channels can curve, spiral, or follow complex contours, ensuring:

- Uniform cooling across the part surface

- Reduced cycle times

- Better dimensional stability

- Lower defect rates (sink marks, warpage, residual stress)

Advantages of Conformal Cooling in Injection Molding

| Advantage | Traditional Cooling (Straight Channels) | Conformal Cooling (3D Printed Tooling) |

|---|---|---|

| Cooling Efficiency | Limited contact, hot spots remain | Uniform cooling, heat removed effectively |

| Cycle Time | Longer due to inefficient heat transfer | Shorter by up to 20–40% |

| Part Quality | Risk of warpage, sink marks, uneven shrinkage | Higher dimensional accuracy, fewer defects |

| Tooling Complexity | Easy to manufacture with drilling | Requires additive manufacturing (metal 3D printing) |

| Cost Efficiency | Lower upfront cost but higher long-term scrap rate | Higher initial tooling cost, but better long-term productivity |

Real-World Applications

- Automotive Components – Bumpers, housings, and under-hood parts benefit from reduced cycle times and lower energy use.

- Medical Devices – Small, high-precision parts where dimensional accuracy is critical.

- Consumer Electronics – Casings and connectors that require aesthetic quality and tight tolerances.

- Packaging Industry – High-volume thin-walled products where seconds saved per cycle add up to major cost savings.

Key Technologies Enabling Conformal Cooling

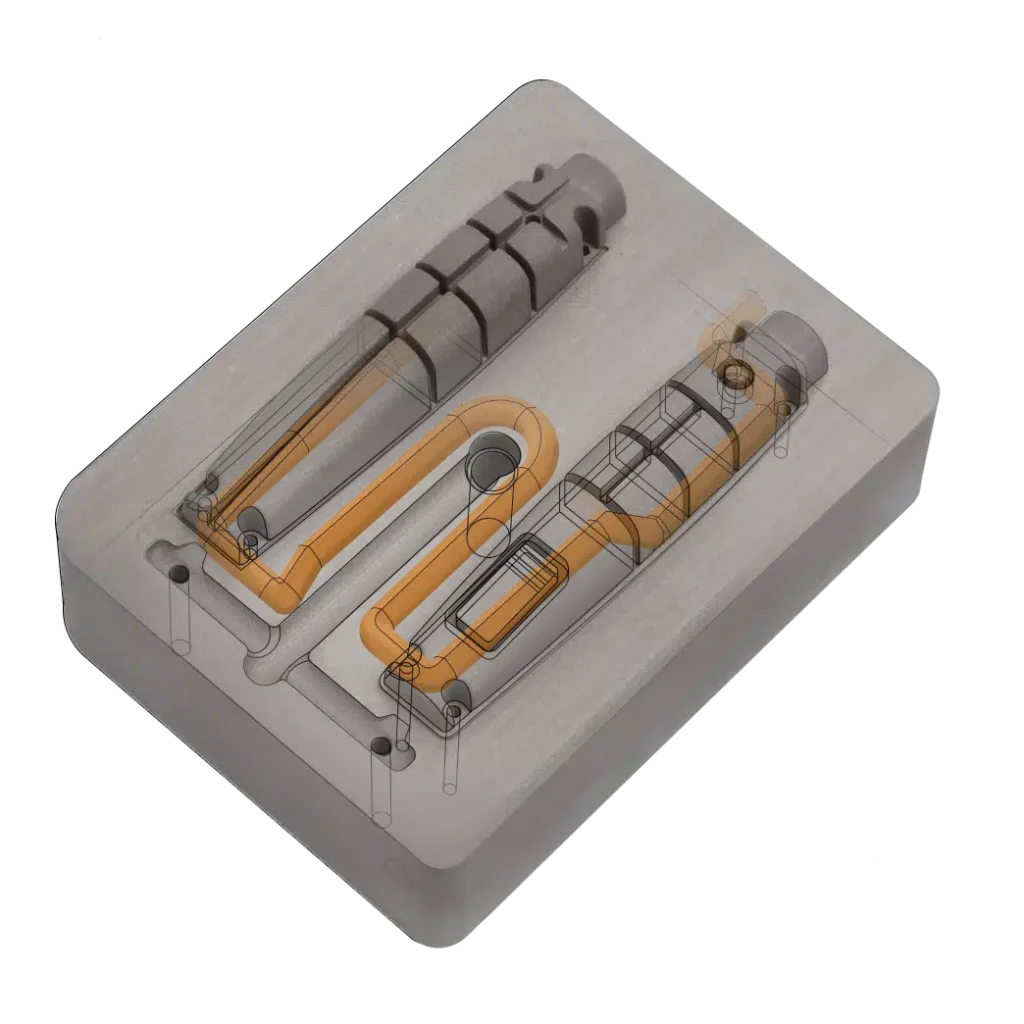

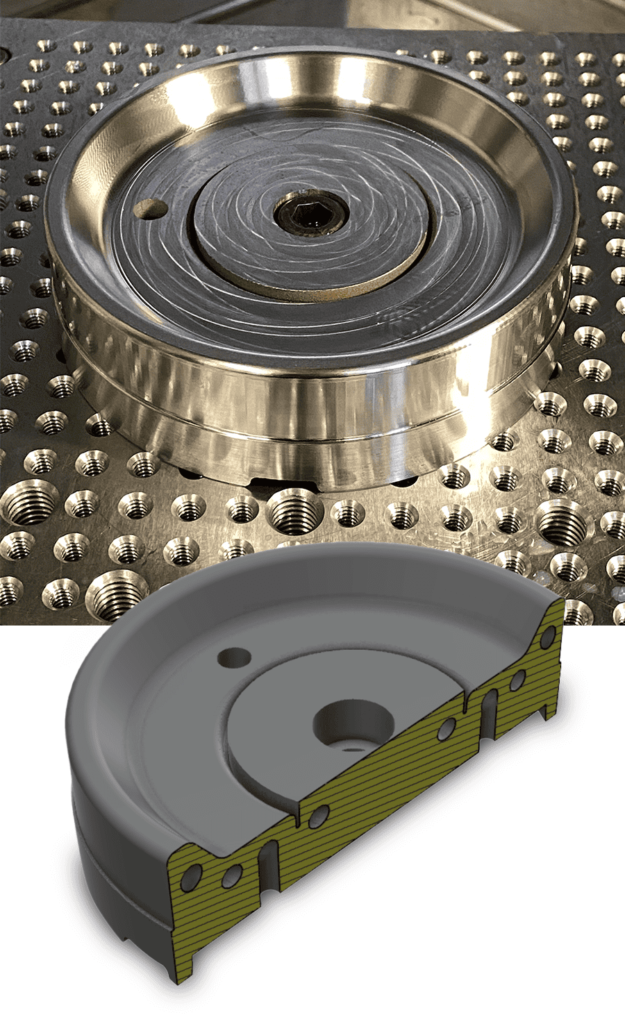

- Metal Additive Manufacturing (SLM, DMLS): Creates complex internal channels impossible to drill conventionally.

- Thermal Simulation Software: Optimizes channel design for maximum efficiency.

- Hybrid Tooling: Combination of conventional machining and AM for cost-effective molds.

Challenges and Considerations

While conformal cooling offers clear advantages, manufacturers must consider:

- Higher Tooling Cost: Metal 3D printing increases initial investment.

- Design Expertise: Requires advanced CAD, simulation, and DfAM (Design for Additive Manufacturing) knowledge.

- Maintenance: Complex channels may be harder to clean and maintain.

Conclusion

Conformal cooling represents a paradigm shift in injection molding, leveraging additive manufacturing to overcome the limitations of traditional cooling systems.

By ensuring faster cycle times, improved quality, and reduced scrap, conformal cooling helps manufacturers achieve greater efficiency and competitiveness—especially in industries demanding high precision and high volume.

As AM technology costs decrease and simulation tools advance, conformal cooling will become a standard practice in modern injection molding, reshaping both productivity and part performance.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.