Introduction

In today’s highly competitive manufacturing landscape, companies are under constant pressure to reduce costs while maintaining product quality and performance. Design for Assembly (DFA) is a systematic design approach that simplifies product assembly by minimizing part count, reducing assembly time, and streamlining manufacturing processes. By integrating DFA principles early in product development, organizations can achieve significant savings in labor, tooling, and overall production costs.

What is Design for Assembly (DFA)?

Design for Assembly (DFA) is a subset of Design for Manufacturing (DFM) methodologies. While DFM focuses on making parts easy to manufacture, DFA emphasizes making those parts easy and cost-effective to assemble.

The primary goals of DFA include:

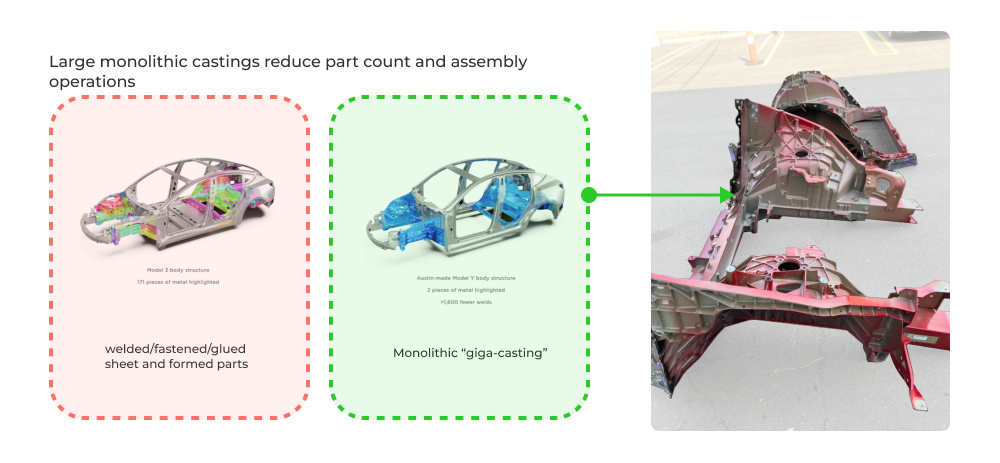

- Minimizing part count

- Simplifying part handling and orientation

- Reducing assembly steps

- Standardizing components

- Improving product reliability through fewer assembly errors

Key Benefits of DFA

- Reduced Assembly Time: Fewer components and simpler assembly steps directly cut labor costs.

- Lower Manufacturing Costs: Simplification reduces tooling needs and error rates.

- Improved Quality: Fewer parts mean fewer opportunities for misalignment or failure.

- Faster Time-to-Market: Simplified assembly accelerates production ramp-up.

- Sustainability: Reduced material and part usage contribute to eco-friendly manufacturing.

DFA in Practice: Examples

| DFA Principle | Traditional Design | DFA-Oriented Design | Impact |

|---|---|---|---|

| Part Count Reduction | 10 fasteners to secure a cover | 2 snap-fit latches integrated into the design | Faster assembly, fewer components |

| Component Standardization | Multiple screw types (M3, M4, M5) | Single screw size used throughout | Simplified inventory & tooling |

| Ease of Handling | Small, fragile washers required during assembly | Washer function integrated into part geometry | Reduced handling time, fewer errors |

| Symmetry in Design | Asymmetric parts requiring orientation | Symmetric, self-locating parts | Faster assembly, reduced training |

| Multi-function Parts | Separate bracket and housing support | Combined bracket-housing component | Lower part cost, improved durability |

DFA and Cost Savings

Studies show that 70–80% of product cost is determined during the design stage. By implementing DFA, manufacturers can achieve cost reductions of up to 30% in assembly labor and 20% in material handling.

For example:

- A consumer electronics company reduced assembly time by 40% by switching from screws to snap-fit joints.

- An automotive supplier saved $1.5 million annually by standardizing fastener sizes and reducing assembly errors.

The Role of Digital Tools in DFA

With advancements in CAD (Computer-Aided Design) and PLM (Product Lifecycle Management) software, DFA analysis can now be conducted digitally before a single prototype is built. Simulation tools allow engineers to:

- Analyze assembly sequence

- Optimize ergonomics and handling

- Detect potential assembly issues

- Calculate cost savings upfront

Conclusion

Design for Assembly (DFA) is not just a cost-cutting technique—it is a strategic approach that improves product quality, reduces complexity, and accelerates time-to-market. In a global economy where efficiency and sustainability are key, integrating DFA early in product development provides manufacturers with a significant competitive edge.

By combining DFA with modern digital tools, companies can deliver simpler, more reliable, and more cost-effective products.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.