Introduction

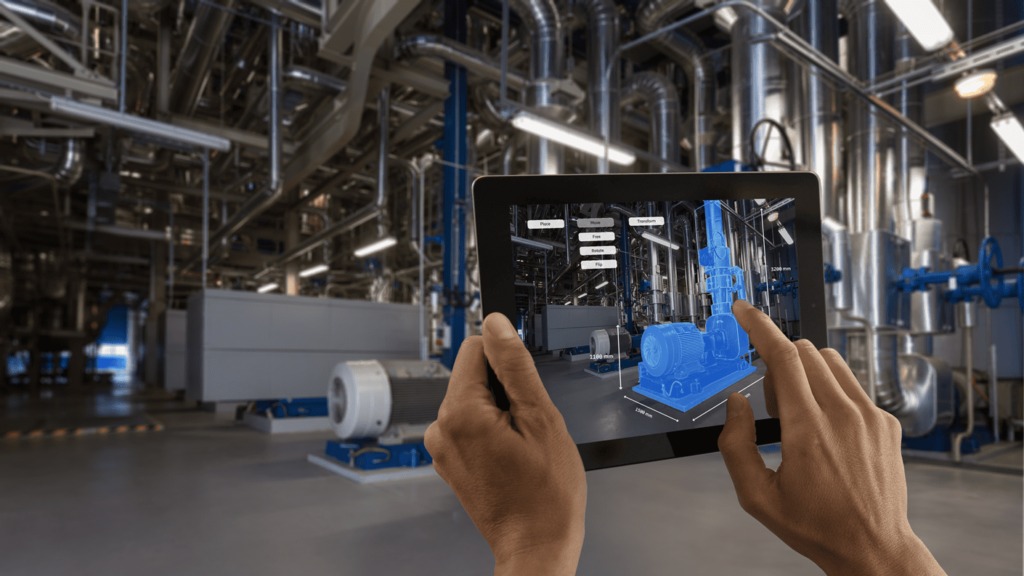

The concept of the digital twin is rapidly becoming a cornerstone of modern manufacturing. A digital twin is a virtual replica of a physical product, process, or production system, continuously updated with real-time data from IoT sensors, simulation platforms, and AI-driven analytics.

By bridging the physical and digital worlds, manufacturers gain powerful insights into design, production, quality assurance, and maintenance, enabling them to innovate faster, reduce waste, and increase operational efficiency.

This article explores the key applications of digital twins in manufacturing, the technologies driving adoption, and how companies can leverage this approach for sustainable, cost-effective production.

What Is a Digital Twin in Manufacturing?

A digital twin in manufacturing is not just a 3D model—it is a dynamic, data-driven environment that evolves alongside its physical counterpart. It integrates:

- IoT sensors capturing real-time machine and product data

- Simulation models predicting performance and failures

- AI & machine learning for optimization and decision-making

- Cloud platforms enabling remote collaboration and scalability

Together, these elements create a closed-loop feedback system that enhances every stage of manufacturing.

Key Applications of Digital Twins in Manufacturing

| Application | Benefits | Example Use Cases |

|---|---|---|

| Product Design & Prototyping | Reduce development time and cost by testing designs virtually. | Automotive crash simulations, aerospace aerodynamics testing. |

| Production Optimization | Simulate workflows and optimize resource allocation. | Smart factories running “what-if” production scenarios. |

| Predictive Maintenance | Forecast machine failures to reduce downtime. | CNC machines monitored for spindle wear. |

| Quality Assurance | Detect defects earlier through real-time inspection. | AI-enhanced inspection in semiconductor or medical device production. |

| Supply Chain Management | Enhance visibility and resilience by simulating logistics. | Virtual models of global supply networks for risk analysis. |

Technologies Enabling Digital Twins

- IoT (Internet of Things): Provides live data from machines, tools, and products.

- Artificial Intelligence & Machine Learning: Powers predictive modeling, optimization, and anomaly detection.

- Cloud Computing: Ensures scalable storage, high-speed processing, and global collaboration.

- AR/VR Visualization: Allows engineers and operators to interact with digital twins intuitively.

- Edge Computing: Enables faster decision-making by processing data closer to machines.

Real-World Examples

- Siemens uses digital twins to optimize factory layouts and monitor robotic assembly.

- GE Aviation applies digital twins to track jet engine health and predict maintenance needs.

- BMW Group develops “virtual factories” to optimize assembly lines before physical rollout.

Challenges to Implementation

While powerful, digital twins come with challenges:

- High Initial Investment – Significant costs for IoT infrastructure, sensors, and cloud integration.

- Data Security – Sensitive production data requires strong cybersecurity frameworks.

- Data Quality & Accuracy – Poor sensor calibration or incomplete data reduces model reliability.

- Integration Complexity – Aligning IT and OT (operational technology) systems remains a hurdle.

Conclusion

Digital twin technology is reshaping how products are designed, manufactured, and maintained. From virtual prototyping to predictive maintenance and supply chain resilience, digital twins enable manufacturers to stay ahead in a competitive landscape.

As Industry 4.0 continues to advance, digital twins will become the foundation of smart manufacturing, enabling faster innovation, sustainable operations, and reduced costs.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.