ZE-TECH rapid injection molding services

Custom Plastic Injection Molding Service

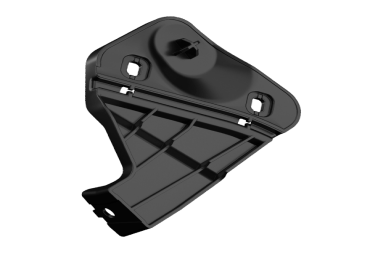

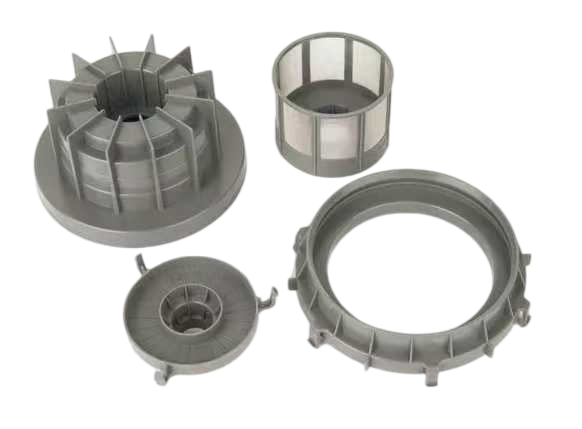

Being one of the professional injection molding manufacturers in China, we are confident to customize your project. Through overmolding and insert molding, we create quality molding parts of different materials and complexity.

There are more than 30+ kinds of materials you can choose from at ZE-TECH to assist your molding project. If you want to create plastic parts of various textures, you can send us the requirements directly.

We can also offer you engineering advice so that you can choose the best processing way and surface finish. ZE-TECH helps you through the entire process of manufacturing your injection molding prototypes and prompt fast deliveries.

Which service would you like?

Here are six Rapid Injection molding services for you to choose from.

We are a well-known injection molding manufacturers in China. Thus, we can render great prototype services by making the best home appliances for you.

We can help you make your investment in the medical products worthwhile by manufacturing the best quality and standard medical prototypes for you using the injection molding method.。

We can also make super flexible and stable rubber products with injection molding for you.

If you’re looking for light-weight and strong resistive plastic parts through injection molding, we can surely help you get the best ABS Plastic Parts.

Electronic products are highly in demand and injection molding is a great process to manufacture them. Ruitai can use this method to provide you super-useful electronic products.

We can help you manufacture sturdy and reliable automotive prototypes all according to your requirements, using the injection molding technique.

What you want to know?

- Services:Rubber Injection Molding,Plastic Injection Molding,Rapid Injection Molding,ect.

- Main Material:PE,PP,PS,PVC,ect.

- Mold Material:Solidified metal,Pre-Hardened steel,Aluminum,Beryllium-Copper ingredient.

- Advantages:Multiple material selection,recyclable materials,high prescision,high-efficiency mass production.

- Tolerance:0.02mm-0.05mm

- Capability:10-100,000 pieces

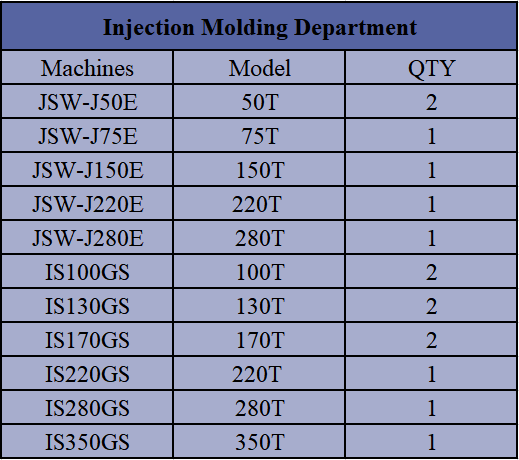

- Machines:15 sets

rapid tooling VS Conventional tooling

rapid tooling

- Mold core customization

- Low cost

- Service Life:50,000

- Lead Time:15-20 days

- Material:Soft steel(p20) Aluminum(7050 T6)

Conventional tooling

- Whole mold customization

- High cost

- Service Life:300,000+

- Lead Time:25-30 days

- Material:steel(P20,S136,718)

mold processing

- Requirement Analyse : DFM Analyse clients needs to ensure smooth production

- Mold Making : Mold making based on clients requirement and communication

- Sample Feedback : TO,T1 sample will sent to client to test and approve

- Production Optimization : Fine-tune manufacturing process for efficiency and quality

- QC and Delivery : 6 times QC and safe package according to the schedule

plastic injection cases

ZE-TECH Rapid Injection Molding Service Frequently Asked Questions

We know that you may have some questions about Rapid Injection Molding services. We have compiled the answers to the following common Rapid Injection Molding project questions, hoping to help you.

What Exactly is Synthetic Injection Molding?

Plastic infusion creating is definitely an cycle that is assembling components are created by infusing liquid plastic sap in to a shape pit. The speed and pressing element at which the product is infused can influence the design that is perfect.

Infusion shaping may be the method toward utilizing plastic to produce a range that is wide of and things. Even though the cycle had been concocted as right on time once the century that is nineteenth it remains possibly the best approach to create complex parts while monitoring expenses.

The infusion device that is forming uniquely crafted molds to round them out as per details, making indistinguishable duplicates that may be modified within an assortment of methods.

Also, infusion forming is an discussion that is incredibly adaptable considering an extensive scope of various materials and completions, which makes it a mainstream choice in incalculable enterprises with completely different objectives and prerequisites.

As a result of this adaptability, the infusion machine that is shaping is even utilized for the most requesting producing projects on earth, delivering parts in aviation, medical areas, and the auto company.

Whether or not you are hoping to supply few parts for screening or require a strategy that is solid producing large numbers of components in a rush, infusion trim is an perfect choice, particularly if working with plastic materials.

Also, the cycle that is novel assembling part with an infusion forming machine also suggests that you are able to produce complex components with multifaceted plans, that isn’t a thing that may be stated pretty much all assembling alternatives online.

The capacity to fabricate enormous amounts of components at a expense that is moderate helps it be undeniably right for the creation of different wares.

How Exactly Does Injection Molding Works?

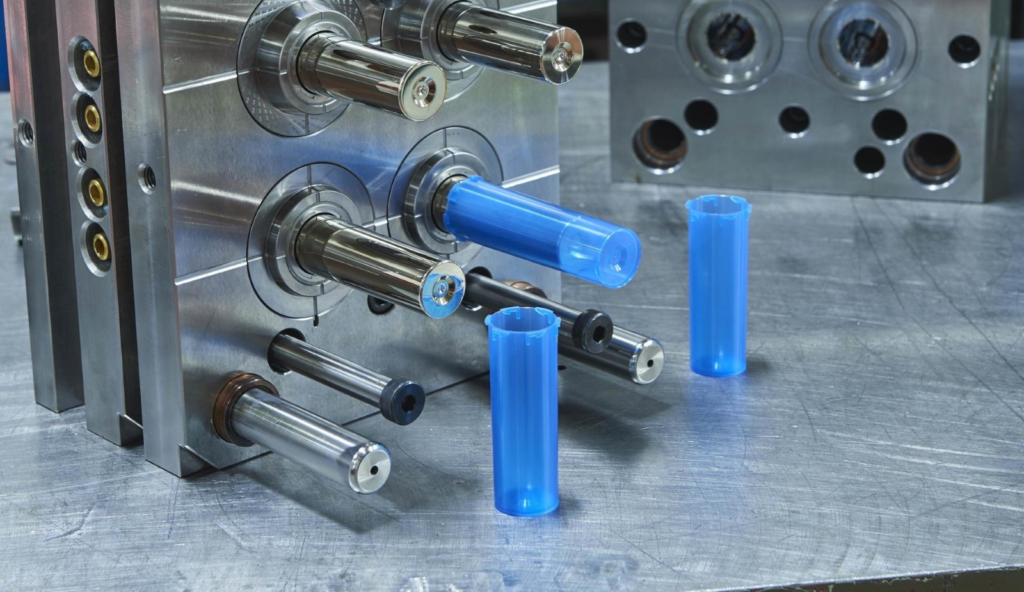

Before any infusion embellishment can start, a form, otherwise known as an device, should be developed. Instruments are planned synthetic that is considering shaping and so are accurately machined out of one or the other steel or aluminum towards the specific detail of the part. Then, the device is embedded to the infusion device that is forming begins the period of infusion shaping.

Thermoplastic tar pellets associated with ideal sap kind have filled a container that protects into the infusion machine that is developing.

Within the wake of chilling off, the gum modifications into a synthetic that is strong and also by, framing the part. At final, the component is launched out of the machine and it is relocated on the stage that is following of. This period is effectively repeatable for creation runs going from hundreds to millions of parts.

Elaborate The Working of Injection Molding?

Although the infusion measure that is forming confounded, it can be sectioned off into a few fundamental improvements that help see how it works and exactly why it is therefore effective.

The infusion developing device is made up of three fundamental sections, that are the feed container, the screw, while the barrel that is warmed.

During the point as soon as the feed container gets the synthetic granules, it at that time uses the activity that is frictional of screw in order to make temperature. If the synthetic arrives at the right temperature, it is then infused in to the cavity that is formed where it eventually cools and takes the shape as indicated by the proper execution plan.

The rehashed infusion may be used in order to make components out of various materials if vital, progressed infusion shaping methods, for example. It is likewise conceivable to use embed trim to add parts which are plastic existing parts made out of various materials.

The fundamental criteria behind the infusion shaping interaction may seem to be easy, yet as a general rule, it’s an extremely confounded cycle that will require the appropriate gear as well as the mastery that’s true. Be that it’s performed efficiently, infusion trim can reliably produce great results the point is, for the most difficult assembling projects as it may, whenever.

How Exactly To Design For Injection Molding?

When planning parts for infusion forming there are explicit models to continue to efficiently produce results being perfect. Divider depth is assessed to make sure that it fits the measures as material component and decision structure should really be figured in. Tightened sides, referred to as draft, are evaluated too. These make the component better to discharge from the infusion machine that is forming permitting atmosphere into the form. Radii are assessed to check whether it might be gainful for the part to own modified corners possibly making the discussion smoother that is trim. Coring away is utilized as being a process to save costs by eliminating material that is additional a section and rendering it empty, while at exactly the same time presenting ribs for proceeded with energy. Coring out likewise lessens sink and stresses through the infusion cycle that is shaping.

Parts is likely to be examined for a policy for manufacturability, or DFM, by infusion disintegrates before heading to the infusion interaction that is shaping. In some instances, a Moldflow reproduction is utilized to dissect and anticipate modifications linked to components within the infusion connection that is shaping. Reproductions give information that permits creators to improve resiliences for parts quickly and decisively before tooling starts.

What Exactly Is Form-Making/Tooling in Injection Molding?

Shape tooling could be the interest that is biggest in the plastic infusion forming measure because of its fundamental work for making the component. Devices are often manufactured from the claim to popularity tooling prepares, but, aluminum can be employed, contingent upon the infusion method that is forming, to create straight down costs within the model phase. Much more at the time of late, 3D printed molds are also just starting to be utilized for early models and shaping that is low-pressure. Before molds are formulated, the parts must certanly be settled, with all the plan frozen, it has been made because it is expensive to improve tooling whenever. Decays and tool developers should work to ensure that the unit configuration satisfies the necessities for the component.

Each type should integrate callouts for breaking up lines, entryways, and ejector markings. Splitting lines would be the relative type of partition in the part between the two shape parts. Doorways are openings in the form where the liquid thermoplastic enters the shape pit from.

What Amount of Time Does It Require For The Manufacturing of Injection Molding?

Making an infusion form needs someplace into the array of 5 and 12 months. The creation period regarding the form for thermoplastic infusion relies upon the intricacy associated with type. The form is created out of two parts, a hard and fast component, and a component that is going. On the chance that is off the mathematics associated with parts is intricate, it will be important to incorporate developments (demolding of undermines) to eradicate the component from the type. Ribs may likewise be embedded to give support that is technical. The ribs increment the intricacy of the infusion creation and kind time. It is feasible to reduce the assembling time by focusing on the program of the type by injection molding manufacturers.

What’re more, different boundaries impact the creation period of thermoplastic infusion form:

The number of impressions (multi-impression shape or otherwise not)

The kind of metal used: hard steel takes additional time to machine. Aluminum, which is gentler, is quicker to machine than steel for instance.

Any area medications.

The completing associated with the right parts(reflect cleaning, and so on)