Learn how to design ribs in plastic injection moulding to avoid sink marks, warping, and voids. Discover rib design guidelines and how Ze-tech Mold provides professional injection molding services for both low and high-volume production.

Introduction

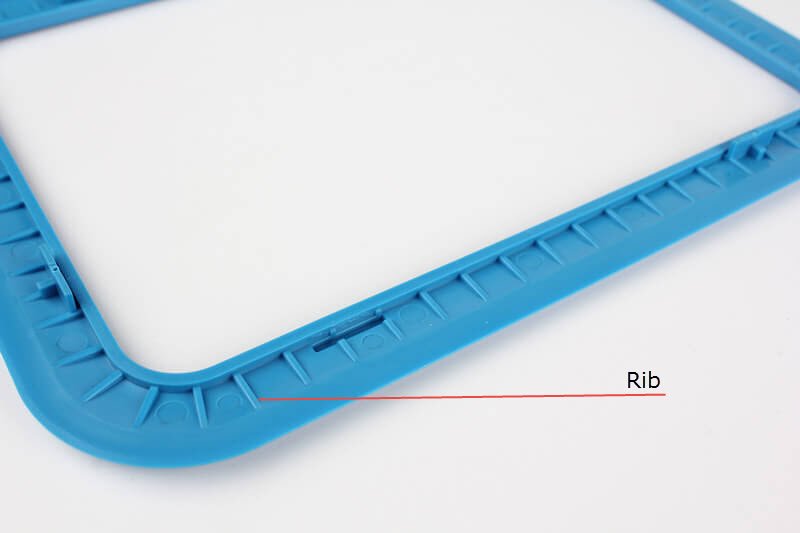

Ribs are thin support structures commonly used in plastic injection moulding designs. They replace thick wall sections to minimize defects like sink marks, voids, and warping, while improving overall part functionality and strength. In addition to structural reinforcement, ribs can also enhance aesthetic appearance when designed correctly.

At Ze-tech Mold, we specialize in injection molding services that integrate rib features seamlessly into part designs. With expertise in CNC machining, rapid injection molding, surface treatments, and PCB assembly (PCBA), we ensure that every project—from prototype to mass production—meets the highest standards of quality and efficiency.

When to Use Rib Features in Injection Moulding

Ribs are particularly effective in the following scenarios:

- Plastic parts requiring maximum strength without increasing wall thickness.

- Parts subjected to pressure, torsion, or bending, where ribs enhance durability.

- Large or complex plastic components, where structural support is critical.

- Lightweight parts that need extra strength without added material usage.

SEO Keyword Focus: injection molding rib design, rib features in plastic parts, plastic injection molding strength

Rib Design Guidelines in Injection Moulding

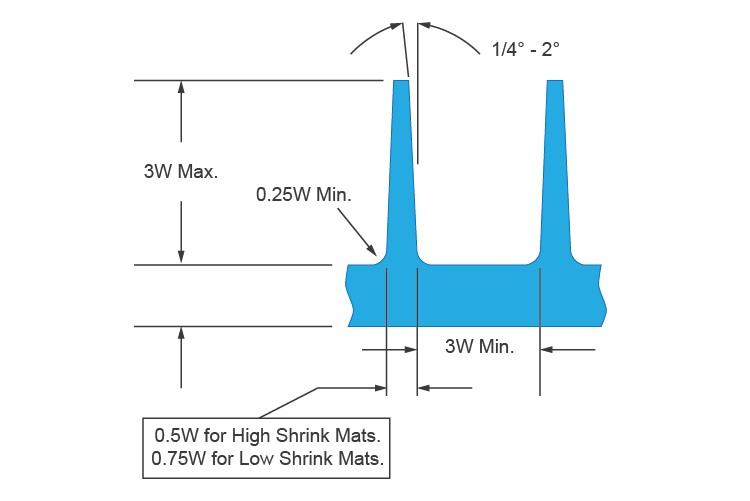

1. Rib Height

- Should not exceed 3× the nominal wall thickness.

- Excessive rib height increases risk of voids, sink marks, and molding difficulty.

- Keep ribs as short as possible while ensuring functionality.

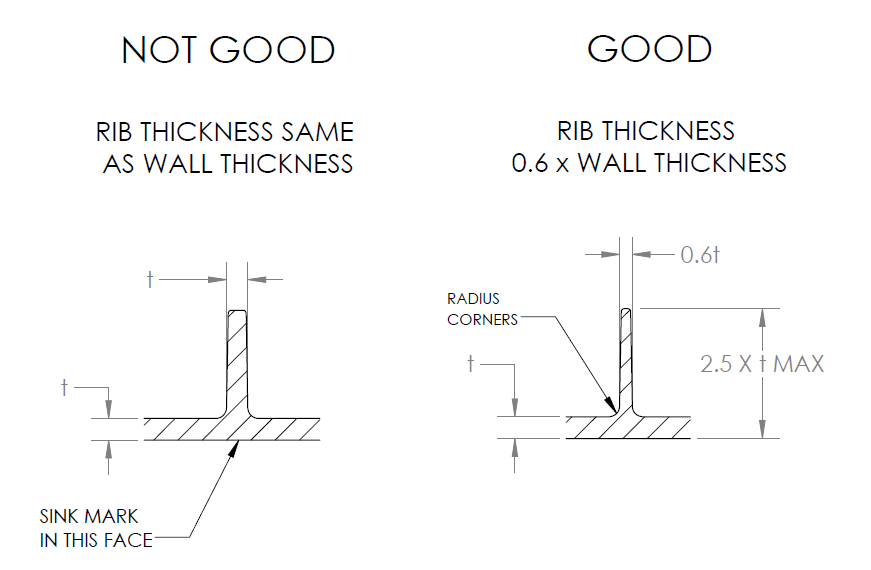

2. Rib Thickness

- General rule: ribs should be ≤60% of the nominal wall thickness.

- Thick ribs can lead to air bubbles, shrinkage patterns, and stress concentrations.

- Optimized rib-to-wall ratio ensures structural balance and better molding results.

3. Rib Radii

- Always add rounded bases with radii to reduce stress concentration.

- Radius should be 0.5–1× wall thickness.

- Rounded ribs improve both strength and moldability.

4. Rib Spacing

- Maintain 2–3× nominal wall thickness between ribs.

- Too-close spacing causes cooling issues, longer cycle times, and increased sink risk.

5. Rib Draft Angle

- Apply at least 0.5° draft per side for easy ejection.

- Only crush ribs should be designed without draft.

Best Practices for Injection Moulding Rib Design

Avoid Excessive Ribbing

Overusing ribs can:

- Prolong cycle times.

- Cause ejection difficulties.

- Increase material waste.

Instead, strategically place ribs where they add the most value.

Ensure Adequate Venting

- Poor venting around ribs may cause short shots, burn marks, sink, and splay.

- Proper vent design reduces injection pressure and ensures consistent quality.

Maintain Uniform Wall Thickness

- Variations in wall thickness create uneven cooling, warping, and dimensional inaccuracies.

- Uniform walls promote better flow, shorter cycle times, and improved part quality.

Avoid Abrupt Transitions

- Sudden thin-to-thick transitions cause sink marks, voids, and stress points.

- Gradual transitions help maintain smooth material flow.

Follow Rib Guidelines Strictly

- Factors like height, spacing, thickness, radii, and draft must be considered together.

- Following guidelines improves mechanical properties and reduces defects.

Summary of Rib Design Guidelines

| Rib Feature | Best Practice Guideline |

|---|---|

| Rib Height | ≤ 3× nominal wall thickness |

| Rib Thickness | ≤ 60% of wall thickness |

| Rib Radii | 0.5–1× wall thickness |

| Rib Spacing | 2–3× nominal wall thickness |

| Rib Draft | ≥ 0.5° per side |

Why Choose Ze-tech Mold for Injection Moulding?

At Ze-tech Mold, we don’t just follow rib design guidelines—we integrate them into every stage of your project to ensure optimal results. Our services include:

- Rapid Injection Molding – From prototype to high-volume production.

- CNC Machining & Turning – High-precision parts with tight tolerances.

- 3D Printing Prototypes – Fast design validation before mass production.

- Sheet Metal Fabrication & Silicone Vacuum Casting – Supporting diverse product needs.

- Surface Treatments – Enhance appearance, durability, and performance.

- PCB & PCBA Services – Complete electronic manufacturing solutions.

Whether you need low-volume prototypes or mass production, Ze-tech Mold provides cost-effective, high-quality injection molding solutions that help you bring products to market faster.

👉 Contact Ze-tech Mold today to discuss your next project.