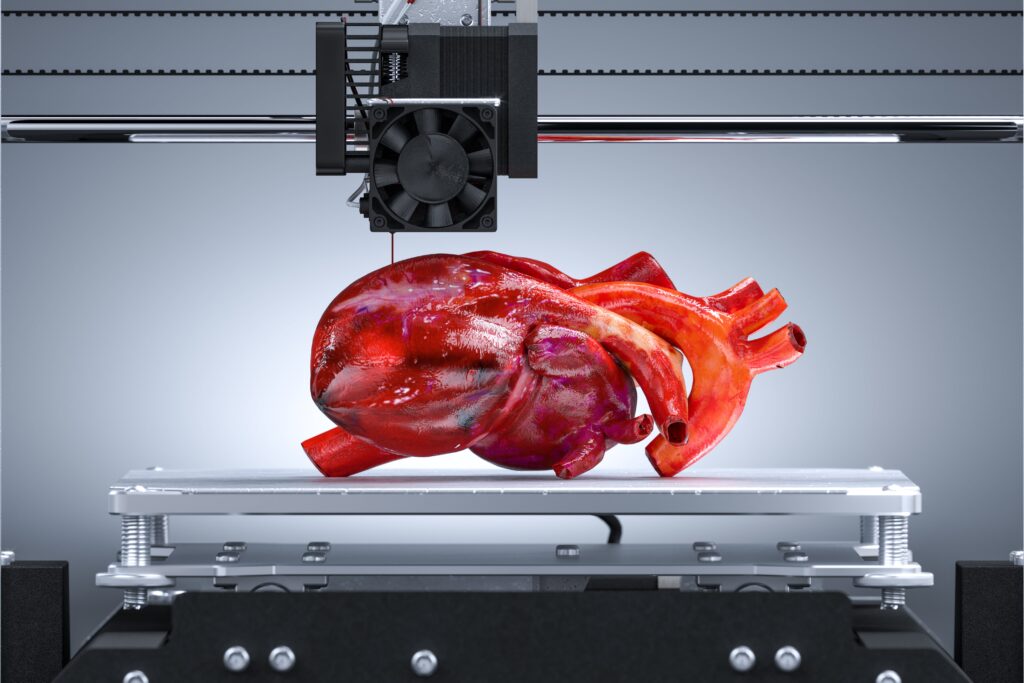

In the highly competitive field of medical device development, accelerating product development cycles is critical. Traditional manufacturing methods often involve lengthy tooling and assembly processes, delaying time-to-market. 3D printing has emerged as a transformative solution, enabling rapid prototyping and significantly shortening development timelines for medical devices.

Accelerating Prototyping with 3D Printing

3D printing allows engineers to create prototypes directly from digital models, eliminating the need for expensive molds and complex tooling. This capability enables the production of functional prototypes within days, facilitating rapid design iterations and early-stage testing. Speed is especially crucial in the medical field, where timely development can have direct impacts on patient care and outcomes.

Companies that integrate in-house 3D printing solutions report reductions in prototyping costs by up to 70% and significantly faster development cycles. Detailed prototypes also improve collaboration with healthcare professionals by allowing more effective evaluation and feedback.

Customization and Patient-Specific Solutions

One of the most significant advantages of 3D printing in medical device development is the ability to produce patient-specific devices. Custom implants, surgical guides, and prosthetics can be tailored to individual anatomical structures, improving patient outcomes and enhancing the efficacy of medical treatments. Patient-specific prototyping supports both clinical precision and regulatory compliance during early-stage product development.

Cost Efficiency and Waste Reduction

Traditional manufacturing often generates substantial material waste due to subtractive processes. In contrast, 3D printing is an additive process, constructing objects layer by layer, which minimizes waste. The elimination of tooling costs and the ability to produce small batches without large setup expenses make 3D printing a cost-effective choice for medical device prototyping.

Real-World Applications

Several medical device companies have successfully adopted 3D printing in their prototyping workflows. For example, Arbutus Medical used 3D printing to develop a surgical tool more quickly and cost-effectively than conventional methods. Similarly, the Bristol 3D Medical Centre in the UK produces custom prosthetic body parts, enhancing patient rehabilitation and comfort.

3D printing is also being applied in complex surgical planning, with anatomical models allowing surgeons to rehearse procedures before operating on patients, thus improving accuracy and reducing risk.

Conclusion

Integrating 3D printing into medical device prototyping is reshaping the industry. By accelerating development cycles, reducing costs, and enabling personalized solutions, 3D printing not only streamlines manufacturing but also improves patient care. As 3D printing technology advances, its applications in the medical field will expand, offering innovative solutions to emerging healthcare challenges.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.