Introduction

In precision manufacturing, where tolerances can reach the micron level, quality assurance (QA) is not an afterthought—it is the foundation of reliable production. From metrology systems to AI-powered inspection tools, modern QA processes ensure that parts meet functional, safety, and regulatory standards.

As industries like aerospace, medical devices, and electronics demand ever-higher accuracy, the integration of advanced metrology, digitalization, and AI inspection has transformed how manufacturers guarantee quality while optimizing efficiency.

Why Quality Assurance Matters in Precision Manufacturing

- Micron-Level Tolerances: A deviation of just 0.01 mm can compromise the functionality of an aerospace turbine blade or a surgical implant.

- Cost Efficiency: Early defect detection prevents scrap, rework, and production downtime.

- Regulatory Compliance: Standards such as ISO 13485 (medical devices) and AS9100 (aerospace) require documented quality checks.

- Customer Trust: Consistently high-quality parts strengthen brand reputation and long-term partnerships.

Core Methods of Quality Assurance

| Method | Application | Advantages | Limitations |

|---|---|---|---|

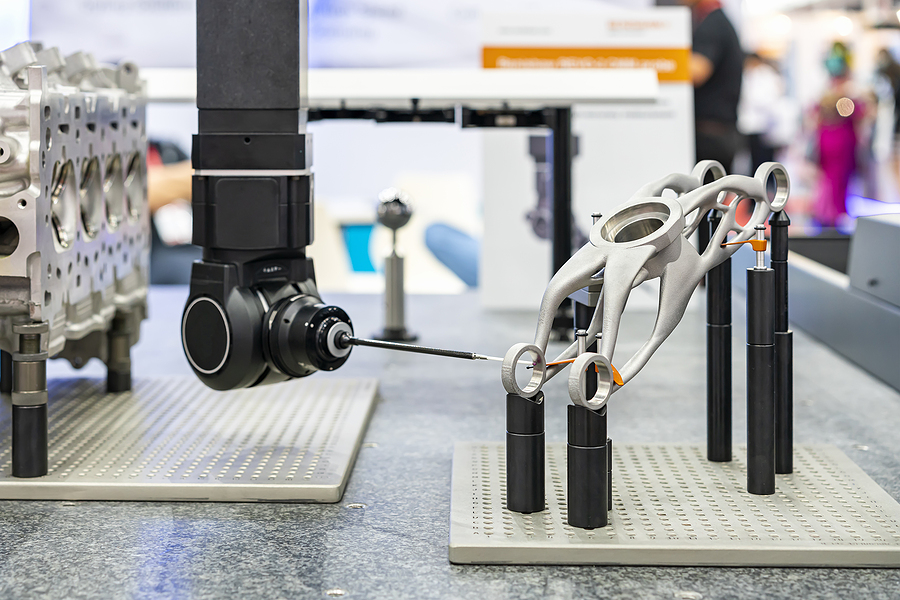

| Metrology (CMM, 3D Scanning) | Measurement of dimensions, surface flatness, and tolerances. | High precision, reliable for complex geometries. | Time-intensive for high-volume production. |

| Non-Destructive Testing (NDT) | Ultrasonic, X-ray, and dye penetrant testing for internal defects. | Detects hidden flaws without damaging the part. | Specialized equipment and expertise required. |

| In-Process Monitoring | Sensors embedded in CNC and molding machines to track tool wear and forces. | Real-time defect prevention, reduces scrap. | Requires integration with machine systems. |

| AI & Machine Vision | Automated image-based defect detection for surface finish and dimensional checks. | High-speed, scalable, adaptive learning. | Requires large data sets for training AI. |

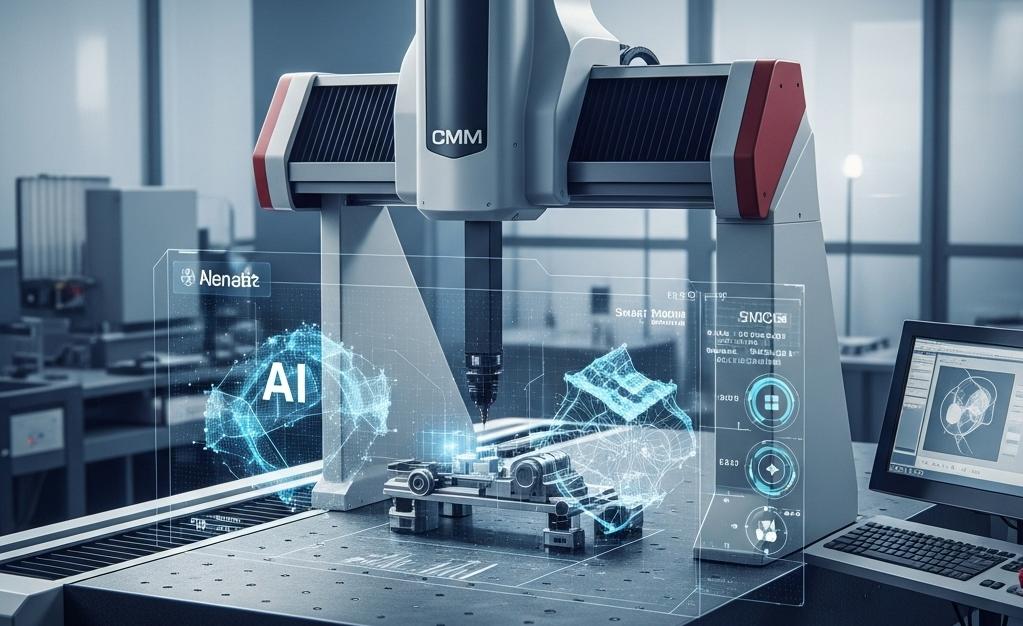

The Shift from Traditional Metrology to AI Inspection

Traditional coordinate measuring machines (CMMs) and calipers are still widely used, but they are being complemented by:

- 3D Optical Scanners – Capture millions of data points for faster full-part validation.

- Inline AI Inspection Systems – Cameras with deep learning detect scratches, warping, or dimensional deviations instantly.

- Predictive Analytics – Machine learning predicts when quality drift may occur, enabling proactive corrections.

This evolution allows manufacturers to balance speed with precision while reducing manual labor.

Industry Applications

- Aerospace – QA ensures turbine blades meet aerodynamic tolerances and composites are free from microcracks.

- Medical Devices – Metrology validates implant geometry, while AI detects microscopic surface imperfections.

- Electronics – Automated vision systems check PCB soldering, alignment, and micro-component placement.

- Automotive – AI inspection validates welds, castings, and machined parts at high throughput.

Challenges in Quality Assurance

- Data Overload: Advanced inspection systems generate terabytes of data requiring efficient storage and analysis.

- High Initial Cost: Investment in CMMs, scanners, and AI inspection systems can be significant.

- Standardization Gaps: AI inspection models lack global standardization, making cross-industry adoption challenging.

Future of Quality Assurance in Precision Manufacturing

- Digital Twins + QA – Simulating inspection outcomes before physical testing.

- AI-Powered Predictive QA – Systems that anticipate failures before they happen.

- Cloud-Based QA Platforms – Collaborative inspection data sharing across supply chains.

- Autonomous QA Labs – Fully automated inspection cells powered by robotics and AI.

Conclusion

From traditional metrology tools to AI-driven inspections, quality assurance in precision manufacturing has evolved into a strategic enabler for efficiency, compliance, and innovation. Companies that embrace these technologies not only improve part quality but also reduce waste, optimize costs, and accelerate time-to-market.

As the industry shifts toward Industry 4.0 and smart factories, AI inspection, digital twins, and in-process monitoring will redefine how precision manufacturing maintains quality at scale.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.