In modern CNC machining, achieving the desired balance between efficiency and precision requires a clear understanding of rough machining and finishing machining. These two stages are fundamental in the manufacturing process, but they serve very different purposes. In this article, we will explore what each process involves, their advantages, and how they compare.

What Is Rough Machining?

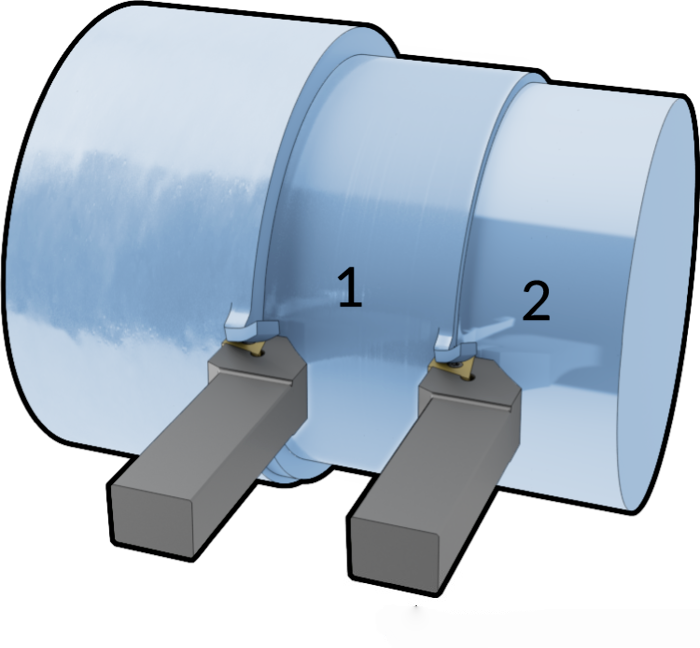

Rough machining is the initial stage of material removal in CNC machining. The goal is to quickly cut away excess stock and shape the workpiece close to the final dimensions.

- Cutting Depth: Large

- Feed Rate: High

- Surface Finish: Rough (Ra typically 3.2–12.5 µm)

- Tolerance: Loose, usually ±0.5 mm or more

This stage prepares the part for precision operations without focusing on surface quality.

What Is Finishing in Machining?

Finishing machining (also called fine machining) is the final step in which the focus shifts to accuracy, smooth surface quality, and dimensional precision.

- Cutting Depth: Small

- Feed Rate: Low

- Surface Finish: Smooth (Ra as low as 0.2–0.8 µm)

- Tolerance: Tight, often within ±0.01–0.05 mm

This ensures the part meets design requirements and is suitable for assembly or end-use applications.

Benefits of Rough Machining

- Efficiency: Rapidly removes bulk material, saving production time.

- Tool Utilization: Uses robust cutting tools designed to withstand heavy loads.

- Preparation: Creates a near-net shape that allows finishing tools to operate efficiently.

- Cost Reduction: Reduces wear on finishing tools by removing unnecessary stock first.

Benefits of Finishing Machining

- High Precision: Achieves tight tolerances required for functional parts.

- Excellent Surface Quality: Provides smooth finishes for better performance and aesthetics.

- Assembly Fit: Ensures components fit correctly without additional rework.

- Improved Performance: Reduces friction and wear in mechanical assemblies.

Rough Machining vs. Finishing Machining: A Comparison

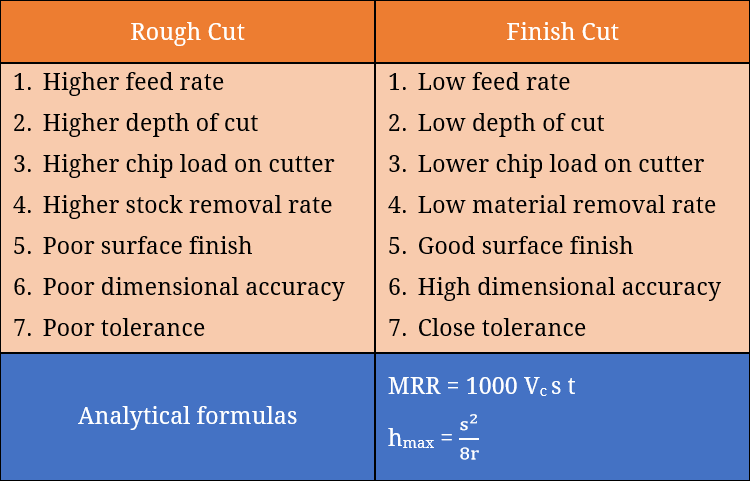

| Factor | Rough Machining | Finishing Machining |

|---|---|---|

| Purpose | Remove bulk material | Achieve final accuracy & finish |

| Feed & Speed | High feed, high cutting speed | Low feed, controlled cutting speed |

| Tolerance | ±0.5 mm or more | ±0.01–0.05 mm |

| Surface Finish | Rough, Ra 3.2–12.5 µm | Smooth, Ra 0.2–0.8 µm |

| Tool Wear | High stress, but short cycle time | Less stress, requires sharp tools |

| Cycle Time | Shorter | Longer |

| Cost | Lower per cycle | Higher, but essential for quality |

When to Use Rough and Finishing Machining Together

In most CNC machining projects, both stages are necessary. Rough machining establishes the geometry efficiently, while finishing machining ensures accuracy and surface quality. For example:

- Automotive Industry: Rough machining engine blocks, followed by finishing for precise cylinder bores.

- Aerospace: Rough shaping of titanium parts, then finishing for critical tolerance control.

- Medical Devices: Rough cutting implants, finishing ensures biocompatible smooth surfaces.

Conclusion

Both rough machining and finishing machining play indispensable roles in modern manufacturing. Rough machining provides efficiency and cost savings, while finishing machining ensures precision, quality, and performance. Choosing the right balance between the two processes depends on material type, part function, and required tolerances.

For industries like automotive, aerospace, and medical devices, combining both stages effectively guarantees high-quality and cost-effective production.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.