Material selection is one of the most critical steps in product design and manufacturing, affecting performance, durability, cost, and aesthetics. Among hundreds of options, ABS, PA (Nylon), PP, POM (Acetal), PC (Polycarbonate), PMMA (Acrylic), and Aluminum are the most widely used.

This article explains their key properties, processing techniques, and common finishing methods, helping designers and engineers make informed decisions.

1. ABS – The Versatile Engineering Plastic

Key Properties

- Excellent toughness and impact resistance

- Good dimensional stability

- Lightweight, easy to mold

- Moderate heat resistance

- Cost-effective

Common Processing Methods

- Injection molding

- CNC machining

- FDM 3D printing

Finishing Options

- Painting, sanding, polishing

- Vapor smoothing (for 3D-printed parts)

- Electroplating for metallic look

- Laser marking or silk printing

Applications: electronics housings, toys, automotive interiors, enclosures

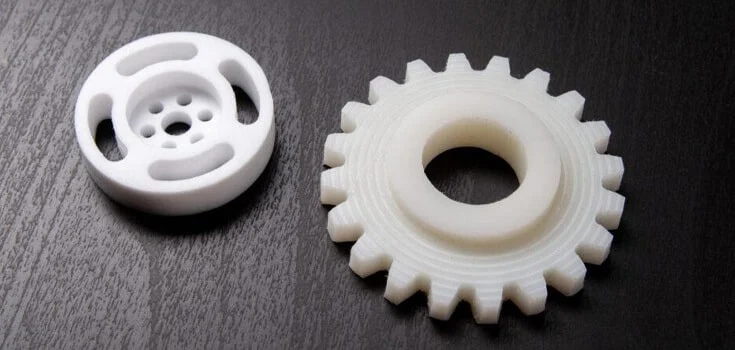

2. PA (Nylon) – Strong and Wear-Resistant

Key Properties

- High tensile strength

- Excellent wear and friction resistance

- Good chemical resistance

- Slight moisture absorption

Common Processing Methods

- Injection molding

- CNC machining

- SLS 3D printing

Finishing Options

- Dyeing, polishing, heat treatment

- Painting (with primer if needed)

Applications: gears, bearings, mechanical components, automotive parts

3. PP – Lightweight and Chemically Resistant

Key Properties

- Extremely light and flexible

- Excellent chemical resistance

- Durable with fatigue resistance

- Cost-effective

Common Processing Methods

- Injection molding

- Blow molding

- Extrusion

Finishing Options

- Surface coating or painting

- Printing or labeling

- Heat welding for joining

Applications: food containers, chemical tanks, automotive ducts, household products

4. POM (Acetal) – Precision Engineering Plastic

Key Properties

- High mechanical strength and rigidity

- Excellent wear and low friction

- Very stable dimensions, low water absorption

- Good chemical resistance

Common Processing Methods

- Injection molding

- CNC machining

Finishing Options

- Polishing and tumbling

- Dyeing or coating for aesthetics

- Chemical smoothing (for 3D-printed parts)

Applications: gears, bearings, mechanical components, industrial machinery

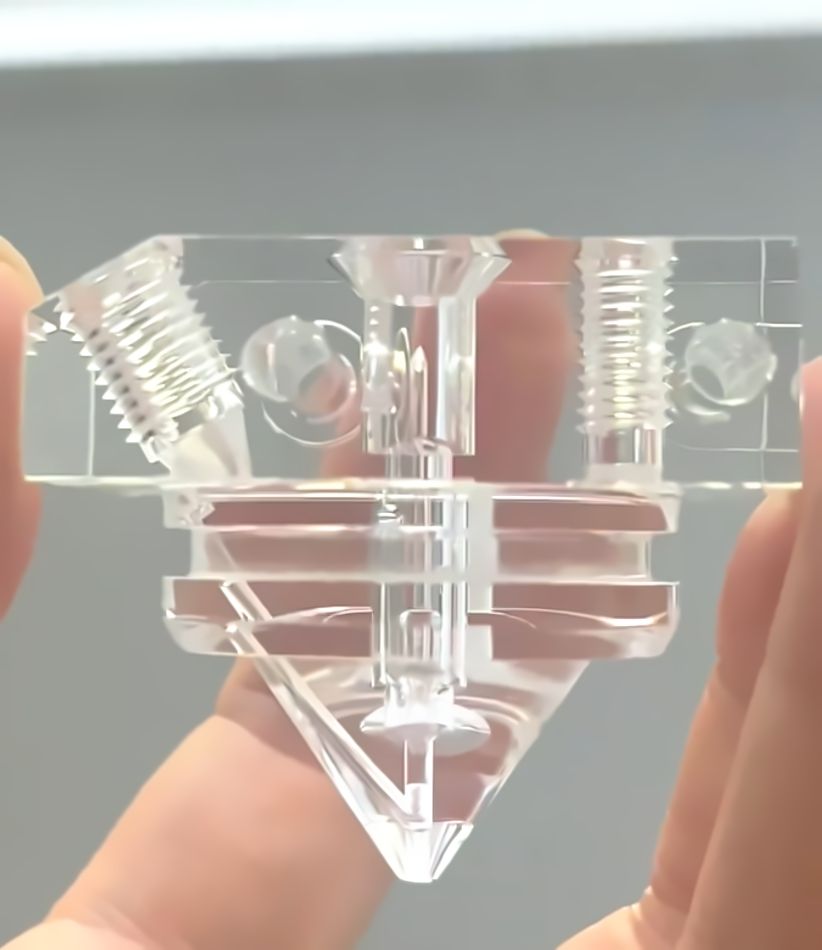

5. PC – High-Impact Transparent Plastic

Key Properties

- Exceptional impact resistance

- High transparency (up to 90%)

- Good heat resistance (~120°C)

- Electrical insulation properties

Common Processing Methods

- Injection molding

- CNC machining

- Extrusion

Finishing Options

- Polishing or flame polishing

- Hard coating to prevent scratches

- Laser marking or silk printing

Applications: headlight covers, electronic housings, protective shields, lighting components

6. PMMA (Acrylic) – Crystal-Clear Plastic

Key Properties

- Ultra-high transparency (~92%)

- High gloss, aesthetically pleasing

- Good UV and weather resistance

- Easy to machine and polish

Common Processing Methods

- CNC machining

- Laser cutting

- Thermoforming / bending

Finishing Options

- Polishing (mechanical or flame)

- Painting for colored parts

- Printing (silk screen, UV printing)

Applications: display boxes, lighting covers, signage, aquarium panels, decorative panels

7. Aluminum – Lightweight Metal for Structural Parts

Key Properties

- High strength-to-weight ratio

- Excellent corrosion resistance

- Can be anodized for colors and protection

- Recyclable, eco-friendly

- Good machinability

Common Processing Methods

- CNC machining

- Die casting

- Extrusion

- Sheet metal forming

Finishing Options

- Anodizing

- Powder coating, painting

- Sandblasting, polishing, brushing

- Laser engraving

Applications: aerospace components, smart devices, automotive parts, industrial equipment

Comparison Table: Key Features

| Material | Strength | Weight | Machinability | Heat Resistance | Wear Resistance | Transparency | Applications |

|---|---|---|---|---|---|---|---|

| ABS | Medium | Light | Excellent | Moderate | Medium | Opaque | Housings, toys, enclosures |

| PA | High | Light | Good | Moderate | Excellent | Opaque | Gears, bearings, mechanical parts |

| PP | Medium | Very light | Good | Moderate | Medium | Opaque | Containers, ducts, tanks |

| POM | High | Light | Good | Moderate | Excellent | Opaque | Gears, bearings, industrial parts |

| PC | High | Light | Excellent | High | Medium | Transparent | Housings, protective shields |

| PMMA | Medium | Light | Excellent | Moderate | Medium | Highly Transparent | Displays, lighting, signage |

| Aluminum | High | Light-to-Medium | Excellent | High | Medium | Opaque / metallic | Structural parts, devices |

Conclusion

These seven materials cover most modern prototyping and production needs:

- ABS: versatile, cost-effective, ideal for housings and prototypes

- PA: durable and wear-resistant, perfect for mechanical components

- PP: lightweight and chemically resistant, great for containers and ducts

- POM: precision, low-friction, excellent for functional parts

- PC: high-impact transparent plastic, suitable for protective parts

- PMMA: crystal-clear and UV-stable, ideal for aesthetic & display parts

- Aluminum: strong, lightweight, perfect for structural and premium components

Why Choose ZE-TECH MOLD?

At ZE-TECH MOLD, we provide one-stop manufacturing solutions for ABS, PA, PP, POM, PC, PMMA, Aluminum, and more:

- Material selection guidance

- CNC machining, 3D printing, injection molding, extrusion

- Finishing: anodizing, painting, polishing, electroplating

- Fast lead times, high-quality standards, global delivery

➡ Contact ZE-TECH MOLD today and bring your design ideas to life!