ZE-TECH Sheetmetal Fabrication services

Sheetmetal fabrication

Processing of sheet metal is called sheet metal fabrication, plastically deforming sheet metal by hand or stamping to the desired shape and size, and can be further welded or machined to form more complex parts. The main processes include bending, stamping, laser cutting, crimping and welding, and the most obvious feature of sheet metal fabrication is the consistent thickness of the part. Sheet metal parts have the characteristics of light weight, high strength, low cost, convenient mass production, etc. Sheet metal processing is widely used in electronic appliances, communications, automotive industry, medical equipment and other fields.

Which service would you like?

Here are three Sheetmetal Fabrication services for you to choose from.

We usually use CNC processing technology to produce high-precision sheet metal parts for you, and this sheet metal workpiece has high consistency.

We provide you with customized sheet metal manufacturing services, you can submit sheet metal drawings to us with confidence, and we will provide you with free quotation services.

We provide you with the production and fabrication of small sheet metal parts in small or large batches. No matter what kind of complex sheet metal is, we can always complete the production tasks of sheet metal parts according to the cycle.

what you want to know

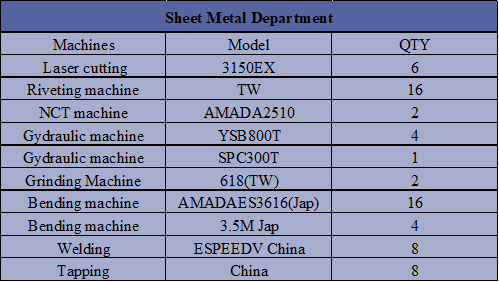

- Services:Riveting,Stamping,Laser cutting,Bending and Welding

- materials:Stainless Steel,Aluminum,Copper,Brass,Galvanized Steel,etc.

- Surface Treatment:Electroplating,Anodizing,Powder Coating,Phosphate Coating,Buff Phosphate Coating,Buff Polishing,Abrasive Blasting

- Tolerance:±0.5mm

- Capability:1-100,000 pieces

- Machine Quantity:67 sets

materials

Stainless steel is a popular choice for sheet metal processing due to its corrosion resistance, strength, and durability. It is often used in applications where hygiene and cleanliness are important, such as in the food and medical industries.

Aluminum is lightweight, strong, and highly resistant to corrosion, making it an ideal material for a wide range of sheet metal applications. It is commonly used in the aerospace and automotive industries, as well as for architectural and decorative purposes.

Copper is a highly conductive metal with excellent corrosion resistance. It is often used in electrical and electronic applications, as well as for decorative purposes.

Brass is an alloy of copper and zinc, and is known for its corrosion resistance and attractive appearance. It is often used in architectural and decorative applications, as well as for musical instruments.

Galvanized steel is coated with a layer of zinc to protect it from corrosion. It is commonly used in outdoor applications, such as for roofing and fencing.

Craft

Bending

Bending is one of the most common sheet metal fabrication methods. The sheet metal is bent into the desired shape by means of a bending machine. When bending, due to certain rebound, the bending angle of the metal is slightly larger than the required angle.

Stamping

Stamping is one of the common sheet metal processing methods. It is an automated and efficient production method to process the metal plate through a die to form holes, bosses, ribs and other structures on the metal plate.

Laser Cutting

Laser cutting is a precision machining method which cuts the material by a high power density laser beam. The material is quickly heated to the vaporization temperature, and evaporates to form a hole. As the beam moves to the material, the hole continuously forms a narrow slit to complete the cutting of the material.

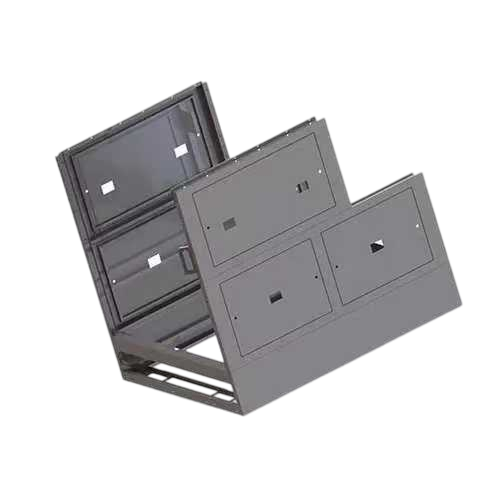

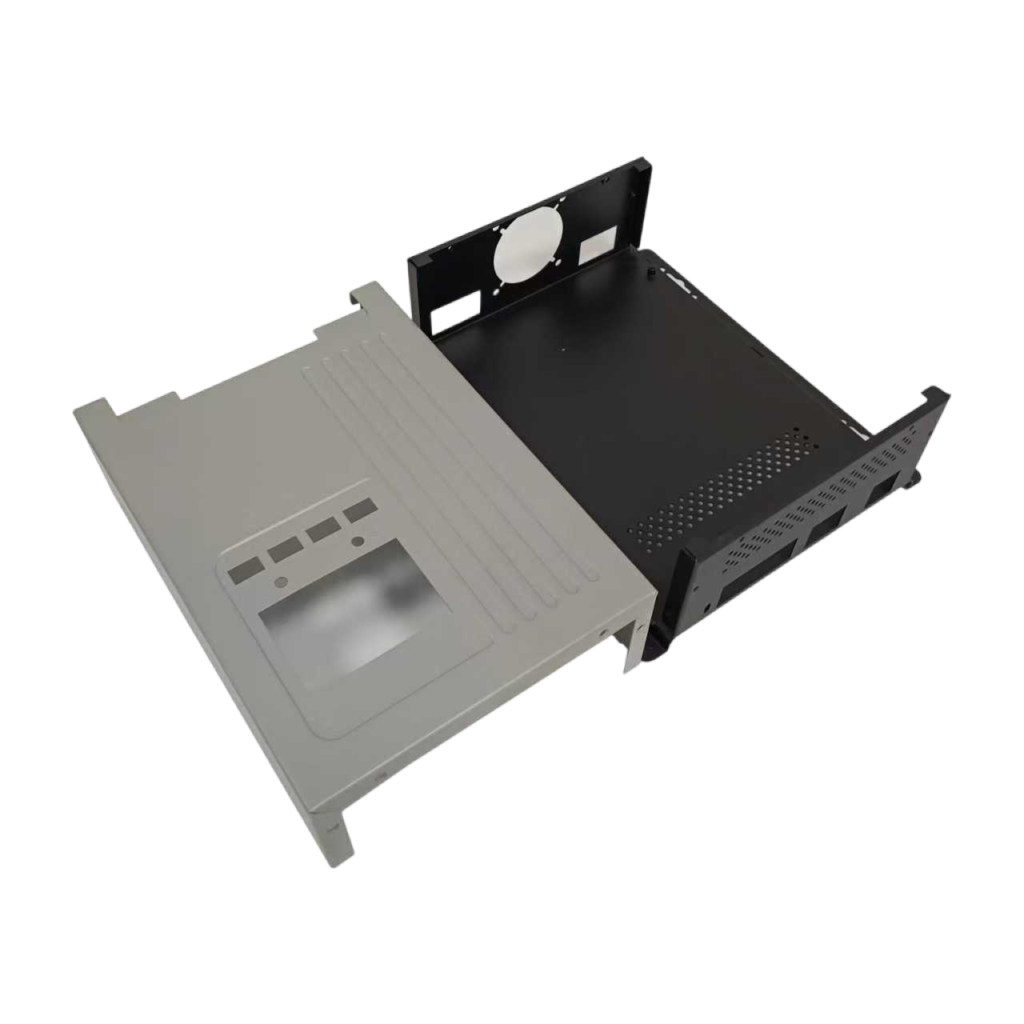

sheetmetal fabrication cases

ZE-TECH Sheetmetal Fabrication Service Frequently Asked Questions

We know that you may have some questions about Sheetmetal Fabrication services. We have compiled the answers to the following common Sheetmetal Fabrication project questions, hoping to help you.

What Kind of Technology Use on Your Sheet Metal Processing Orders?

Normally, there are a lot of kinds of technology used on sheet metal processing parts: welding, cutting, bending, punching, forming, rolling, joining, and more. But do not worry, ZE-TECH will make your custom sheet metal processing parts according to your CAD files and 2D files. We will choose the right and economical way for your sheet metal processing parts.

How Many Surface Treatment We Can Make On Your Sheet Metal Processing Projects?

ZE-TECH can make different kinds of surface treatments on your sheet metal processing orders. It includes passivation, zinc plated, powder coated, painting, nickel plated, color plating, copper plated, black coated, etc.

If you have more questions about sheet metal processing surface treatment, just let us know.

What Are the Shapes Of Sheet Metals?

Usually, you can find two shapes of sheet metals available. One is a flat sheet that is the rectangular shape of a metal sheet that is flat and uniformly thicken. Whereas another shape is coiled sheet metal. A flat sheet is typical, while the coiled sheet metal is formed through roller slitters.

What Products Can You Make from Sheet Metal?

It is really hard to find out any industry that is not consuming sheet metal. A significant example is the automobile industry that needs sheet metal for car frame formation. Also, trucks, buses, aeroplane bodies are manufactured using these sheet metals.

Another big example that you can find is the body of various computers, laptops, printers, photocopiers, cellular phones, all made of sheet metal. The electrical industry is also dependent on sheet metals. For example, transformers body, main switch bodies, connections, terminals, carriers, etc., are made of sheet metals.

The food industry also uses sheet metal to form food container tins. You can also notice many products like furniture, fences, signs, lamps, vessels all made of sheet metal.

Why Do You Achieve Edge Rounding of Metals in Sheet Metal Processing?

You reduce the sharpness of the edge with edge rounding. This is important to make sheet metals useful and reliable to make them safe for industrial and other usages in homes. The food and chemical sector also requires edge rounding for lacquering and coating their products.

What Are the Differences Between Cold and Hot Forming in Sheet Metal Fabrication?

As you can comprehend by the name, cold forming requires less temperature, whereas hot forming is done at high temperatures. Both have their own advantages and disadvantages.

In hot forming, you apply specific techniques under high temperatures to achieve better formability. You might experience poor dimensional tolerances as well as scored surfaces in the hot forming process, which are probably its major disadvantages.

Whereas you can get precise dimensional tolerances through the cold-forming process. You do not have to heat the material, which results in increased strength. But this cold-formed workpiece could only be welded if you soft annealed, thus minimizing stress.