ZE-TECH silicone vaccum casting services

silicone vaccum casting

If you are looking for a manufacturing way to create low-volume plastic parts, vacuum casting may be one of the most popular and cost-effective ones. The vacuum casting prototypes are often applied to test your unique design. Here are the details about tolerance that we offer you:

- As for the tolerance of silicone mold, it can reach around±0.1MM. After checking and assembling, we vacuum casting services will continue making more silicone molds to create more prototypes.

- The tolerance on finished parts can reach +-0.15MM.

- If the size of vacuum casting parts is more than 1000MM, the tolerance on the parts can reach +-0.2MM.

Which service would you like?

Here are six silicone vacuum casting services for you to choose from.

It has been a popular manufacturing method to create car components like grilles. It helps a lot to verify the feasibility of your design.

The transparent materials we used on car light are PMMA and clear PC.

Carbon fiber is one of the common materials for plastic vacuum casting project.

Rubber shore is one type of samples we made. You can send any requirements to us and we will create the casting parts accordingly.

ABS is the most common material used for vacuum casting.

We usually apply vacuum casting to create front and rear bumpers with the maximum size of 2 meters.

What you want to know?

- Production:Suitable for small batch production,up to 25 per mold for typical quantities

- Tolerance:±0.15mm

- Advantage:Low cost,short production cycle,Ability to reproduce complex geometry and details

- Material:Rubber,ABS,PE/PP,ect.

- Minimum wall thickness :0.75mm at least 1.5mm at best

- Maximum Dimensions:1900*900*750mm

8 Steps to Create Custom Vacuum casting Parts

Here are 8 steps that we take to create custom vacuum casting parts below:

Create a master pattern

The first step is to create a master pattern or prototype of the custom part using 3D printing, CNC machining, or other prototyping methods.

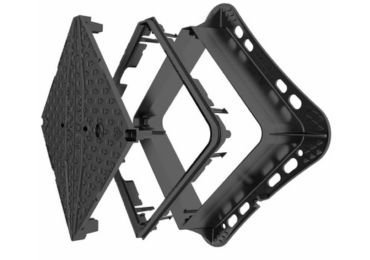

Build a silicone mold

A silicone mold is created by pouring silicone rubber around the master pattern. This mold will be used to create the actual parts.

Prepare the casting material

The casting material is prepared by mixing a two-part polyurethane resin or other casting material according to the manufacturer’s instructions. The resin is then poured into a mixing container.

Vacuum the casting material

The mixing container is placed inside a vacuum chamber and the air is removed from the resin mixture. This process ensures that there are no air bubbles in the final part.

Pour the casting material

Once the resin mixture is fully vacuumed, it is poured into the silicone mold through a small opening.

Cure the casting material

The casting material is left to cure for the recommended amount of time, which is usually several hours.

Remove the part from the mold

Once the casting material is fully cured, the part is removed from the silicone mold. The mold can be reused to create additional parts.

Finish the part

The part may need to be trimmed or sanded to remove any excess material or imperfections.

Repeat the process

The process can be repeated to create additional parts as needed. At the same time, we can only reuse the silicone mold from 20 to 25 times. Or else, its accuracy will be greatly influenced.

silicon vaccum casting cases

ZE-TECH Silicone Vaccum Casting Service Frequently Asked Questions

We know that you may have some questions about Silicon Vaccum Casting services. We have compiled the answers to the following common Silicon Vaccum Casting project questions, hoping to help you.

What Kinds of Material Can Be Used For Vacuum Casting?

ZE-TECH have many kinds of material for vacuum casting including rubber, similar ABS/PP/PC/PE. And the color is customizable. We will mix up the color according to your requirements.

If you are wondering how vacuum casting was developed? Well, this method was first used in the 1960s in the German lab by using silicone molds. It is considered the most cost-effective way of prototyping in which you have to maintain a correct optimum temperature while you are curing the materials.

It is a reliable method because we get high quality and fine detail finished products through this process. As it is a super-fast method, this makes it best when you have to catch your deadlines quickly.

What Is Vacuum Casting?

The process in which we use a vacuum to mold a molten material is termed vacuum casting. This process is used when the material is fiber, or wire-reinforced.

In this process, a small series of functional plastics parts are produced. Polyurethanes and silicone molds are two essential components are used in this process. People tend to apply it for high-quality prototypes or end-use products.

Are There More Types and Other Ways of Vacuum Casting?

The method in which you wait for the liquid metal to cool and solidify to obtain the part is called metal liquid casting.

Here, we have short-listed a few casting method types for you.

- Vacuum die casting

- Sand Casting

- Centrifugal casting

- Investment casting

- Low-pressure casting

- Gravity die casting

- Die casting

- Lost foam casting

- Squeezing die casting

- Continual casting

Why Is A High-Quality Master Model Important In Vacuum Casting?

A first-class master model requires for the process of vacuum casting. Additionally, you can create your master model using stereolithography, or the master model can be a part of the industry.

You should make sure about one thing that the master model should be of correct dimensions and look. When we use the acceptable quality master model, we have the warranty that we can get the product without any flows.

How Does The Cure Process Work In Vacuum Casting?

Resin for the master replica is encapsulated in a silicone mold. After this, silicon mold closely strengthens by high temperature and makes the silicon more durable.

After the curing process, mold is cut at the middle to reveal the hollows. The hollow space in the center has the exact dimensions like the master model. When the mold is divide into two, it becomes ready to go into the chamber. Then the required product is produced by filling up the mold.

Why Is Resin Used In Vacuum Casting?

Now at this stage, fill the mold with the selected material. The resin possesses the same properties as any industrial substance. You can easily get all kinds of functional or mechanical properties with the resin.

When the cast is filled with resin, we have put it in the chamber so that no bubbles or spaces are left out in the mold. It ensures that the product will be flawless and will not be damaged or ruined.