In manufacturing, surface finishing is more than just making a product look good—it plays a critical role in functionality, durability, and performance. From improving wear resistance to enhancing electrical conductivity, surface finishing processes are essential for industries ranging from automotive to aerospace and medical devices.

This article explores the importance of surface finishing, common techniques, and how manufacturers choose the right finishing method for each application.

Why Surface Finishing Matters

Surface finishing improves both form and function of manufactured parts. Its impact can be categorized into two main areas:

- Aesthetics

- Enhances visual appeal with smooth textures and uniform colors.

- Provides branding value in consumer-facing products.

- Functionality

- Reduces friction, improves corrosion resistance, and increases fatigue strength.

- Ensures components meet regulatory and performance standards, especially in critical industries.

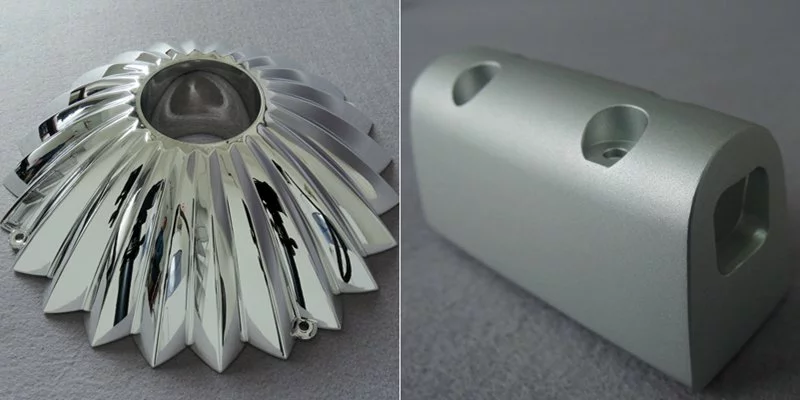

Common Surface Finishing Techniques

| Technique | Description | Applications | Key Benefits |

|---|---|---|---|

| Anodizing | Electrochemical process forming an oxide layer on aluminum. | Aerospace, electronics housings | Corrosion resistance, improved adhesion, color |

| Electroplating | Coating metal surface with thin layer of another metal. | Automotive parts, consumer electronics | Enhanced appearance, wear resistance, conductivity |

| Powder Coating | Dry powder applied and cured under heat to form a protective finish. | Appliances, automotive components | Durable, eco-friendly, wide color options |

| Polishing & Buffing | Mechanical processes to smooth and shine a surface. | Medical devices, decorative parts | Aesthetic appeal, reduced surface roughness |

| Passivation | Chemical treatment for stainless steel to remove impurities. | Medical implants, food processing equipment | Improved corrosion resistance, longer lifespan |

| Shot Peening | Bombarding surface with small spherical media to induce compressive stress. | Aerospace, automotive critical parts | Increases fatigue resistance, strengthens surface |

Choosing the Right Surface Finish

Selecting the right surface finish depends on several factors:

- Material type: Aluminum, steel, plastics, and composites each require different processes.

- Functionality: Whether the priority is corrosion resistance, conductivity, or strength.

- Industry compliance: Medical, aerospace, and defense sectors demand finishes that meet strict standards.

- Cost and scalability: Balancing performance benefits with production efficiency.

Industry Applications

- Aerospace: Shot peening and anodizing for fatigue resistance and lightweight protection.

- Medical Devices: Polishing and passivation ensure biocompatibility and hygiene.

- Electronics: Electroplating enhances conductivity for connectors and circuit parts.

- Automotive: Powder coating and electroplating for durability and visual appeal.

Conclusion

Surface finishing in manufacturing is not just about aesthetics—it is a performance-critical step that enhances part durability, compliance, and end-user satisfaction. By combining the right technique with the right material, manufacturers can achieve both functional excellence and long-lasting products.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.