ZE-TECH surface treatment services

Surface Treatment

ZE-TECH offers you a complete service of surface treatments to save your time and cost. There are Painting, Polishing, Anodizing, Electroplating, Passivation, Blackening, Sandblasting, Laser Engraving, Powder Coating, etc.

Finishing thickness: Common oxidation thicknesses are 5µm, 10µm, and 15µm;

Hard anodized film generally requires 25-150µm;

The thickness of the oxide film formed by passivation is generally between 0.1-10 µm;

Galvanizing thickness requirements are usually between 65 µm and 85 µm;

Oil spray, single coating–10~20 µm

Double layer coating–30~40 µm

Rubber oil–50~60 µm.

Service Type

Enhance the functionality and aesthetics of your CNC machined parts with our comprehensive surface finishing services. From anodizing and plating to polishing and coating, we ensure that every component meets the highest standards of quality and durability.

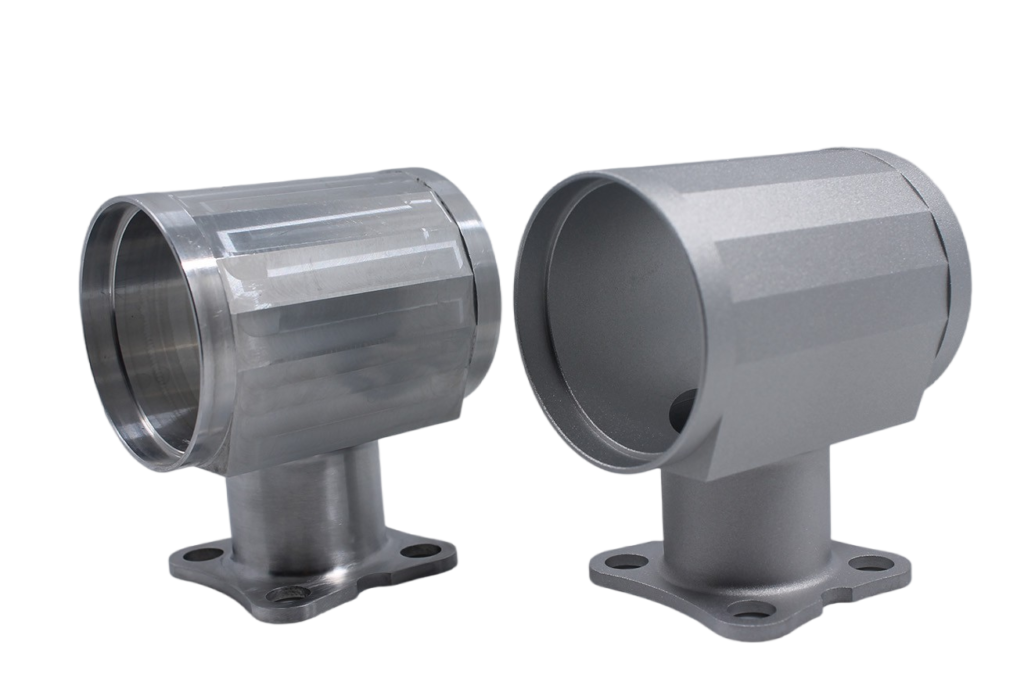

Anodizing

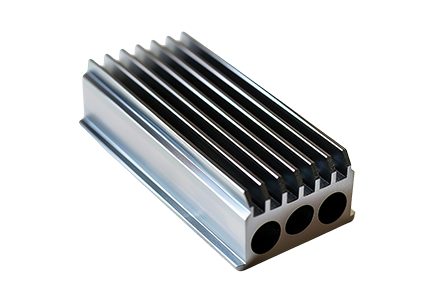

ZE-TECH has its own oxidation plant and is a specialist in anodized aluminium, magnesium and titanium. Anodizing not only provides a beautiful appearance color, but also increases the hardness and durability of the workpiece, and in some cases, it’s a more ideal finish than painting.

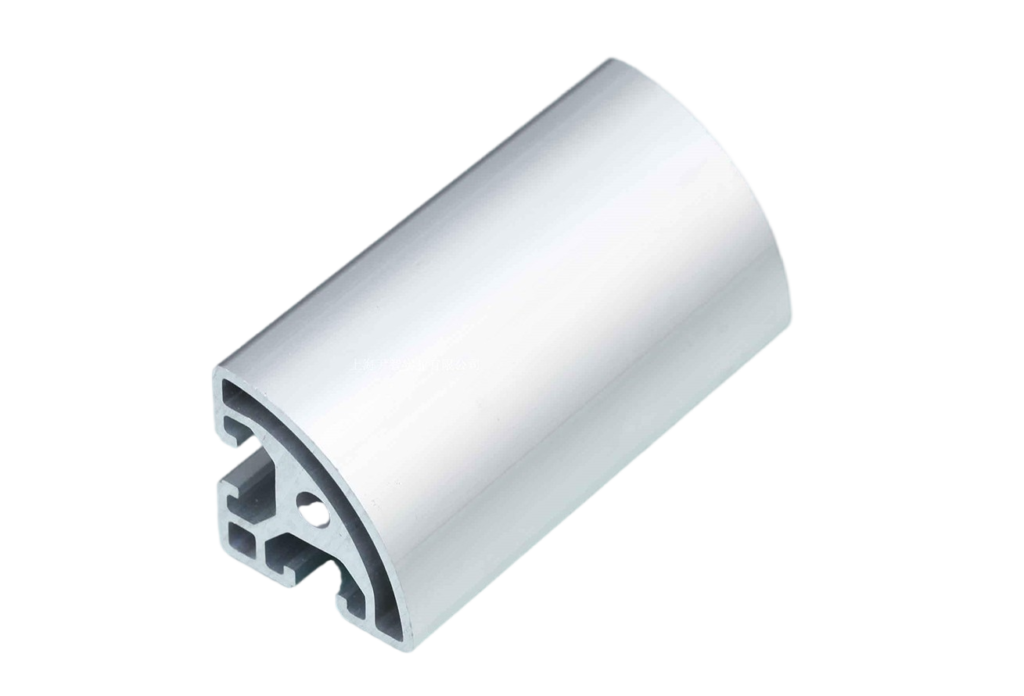

Sandblasting

Sandblasting sprays fine sand to the workpiece through high-pressure airflow, which can form a unique texture while removing burrs and stains on the surface of the workpiece. Sandblasting can be used as a final treatment, or be prepared for subsequent surface treatment to increase the bond strength between the workpiece and the coating/plating. it’s a more ideal finish than painting.

Painting

ZE-TECH has specific painting equipment, which can spray the product from any direction. Thousands of colors can be prepared by experienced sprayers, and the surface effect can be selected from matte, semi-gloss and full-gloss finishes, ensuring that the spraying quality can satisfy customers’ requirements.

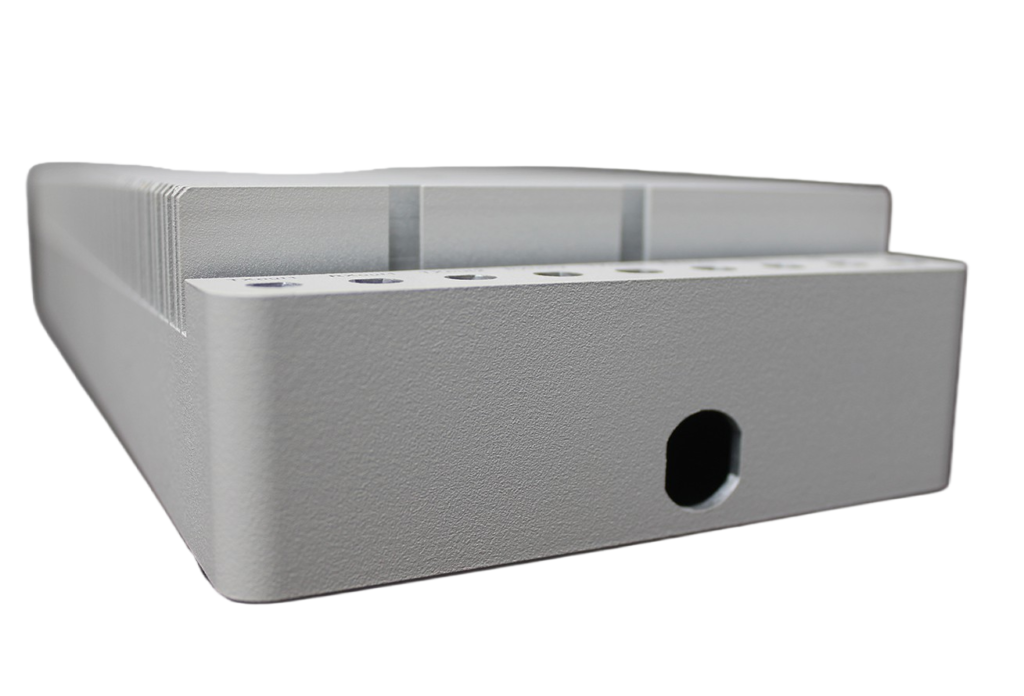

Powder Coating

Use professional equipment to spray electrostatic powder on the surface of the workpiece to form a uniform coating with different effects. ZE-TECH always insists on protecting the ecological environment, and carries out environmentally friendly production on powder coating, so that the entire production process can reach a pollution-free state.

PVD

PVD is an environmentally friendly process. The plated film has the characteristics of high hardness, wear resistance, corrosion resistance, high chemical stability and long life. It can be plated with various film colors and finishes, which greatly improves the appearance of the workpiece.

Electrophoresis

This process can obtain a uniform and smooth paint film on the inner layer, depression, welding seam and other parts of each component, which solves the problem of painting complex-shaped workpieces by other painting methods, and the product has a long-lasting bright color and works well on corrosion resistance.

Electroplating

Electroplating includes vacuum electroplating, UV electroplating, plastic electroplating, and metal electroplating; its technology is widely used, suitable for mass production, and is easier to mechanize and automate production.

Passivation

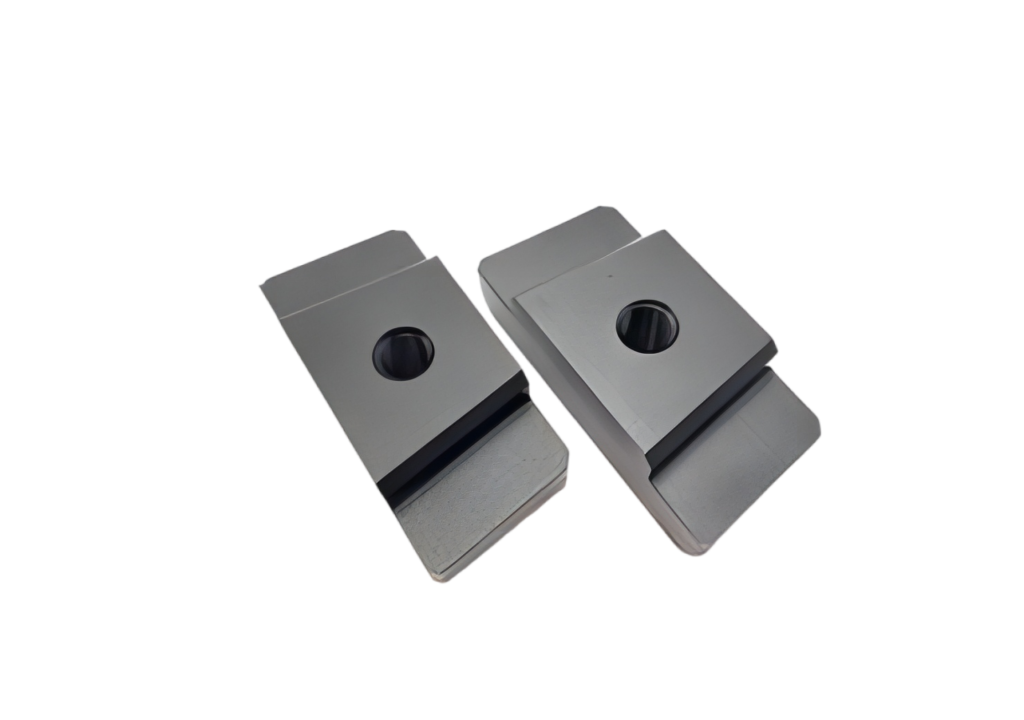

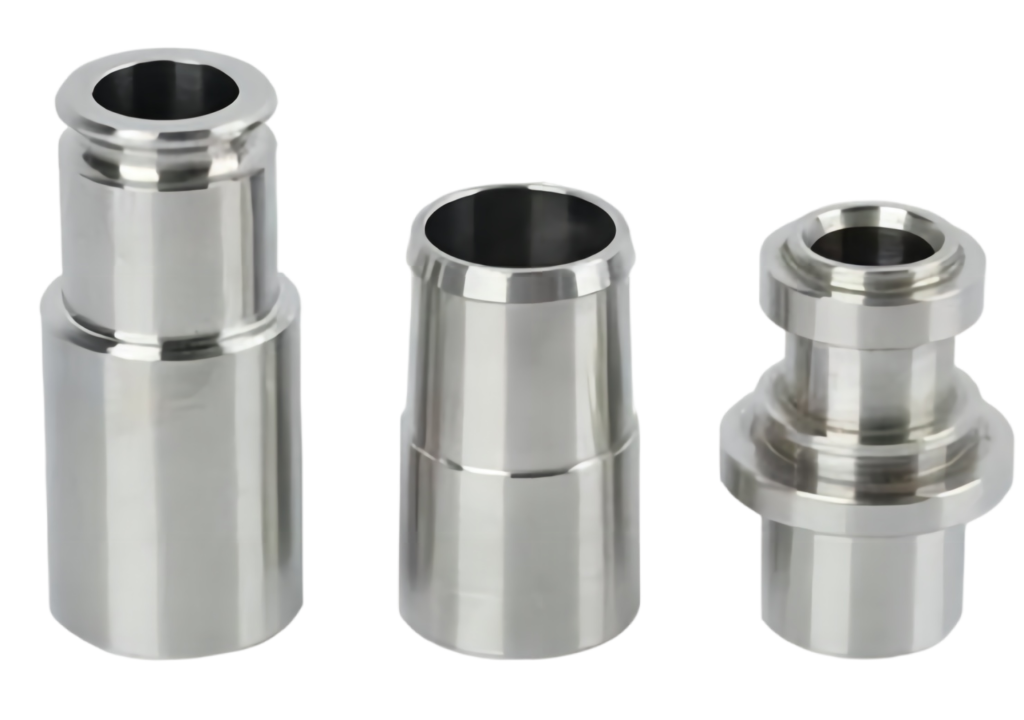

Passivation has the characteristics of not increasing the thickness of the workpiece and changing the color, improving the precision of the product and the anti-corrosion ability of the metal, and also maintaining the characteristics of the metal surface and increasing its added value.

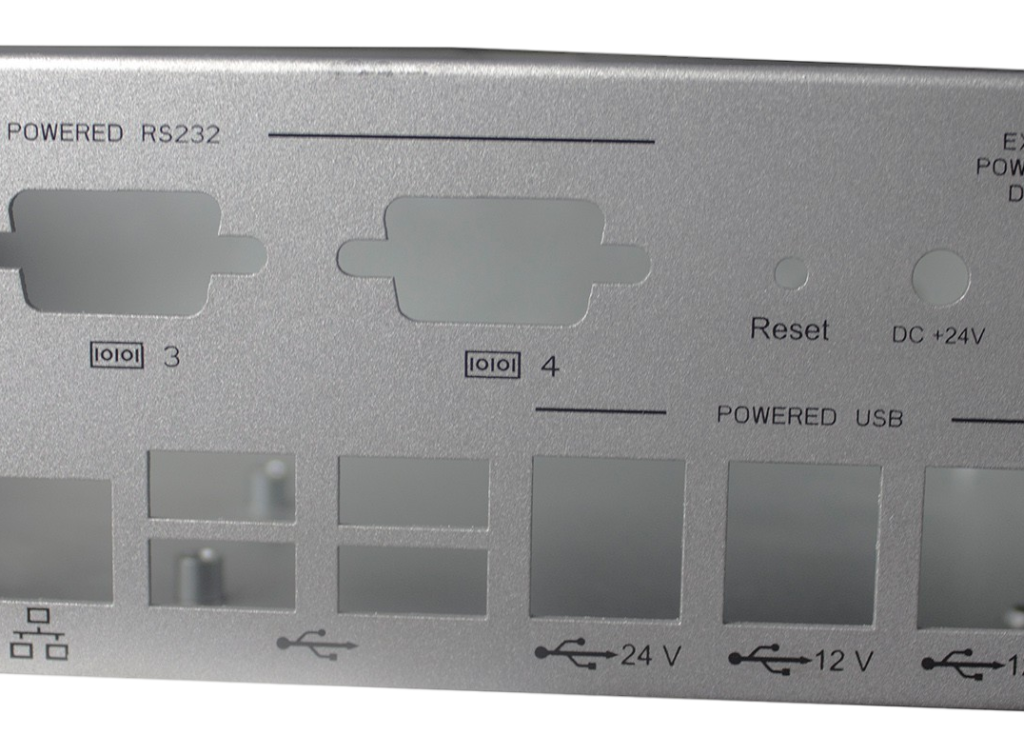

Laser Engraving

Electroplating includes vacuum electroplating, UV electroplating, plastic electroplating, and metal electroplating; its technology is widely used, suitable for mass production, and is easier to mechanize and automate production.

Silkscreen Printing

ZE-TECH’s silkscreen printing can be freely adjusted with various inks and coatings, so that the silk printing pattern can achieve a colorful, bright and strong three-dimensional effect. And the printing method can be used in various materials and shapes.

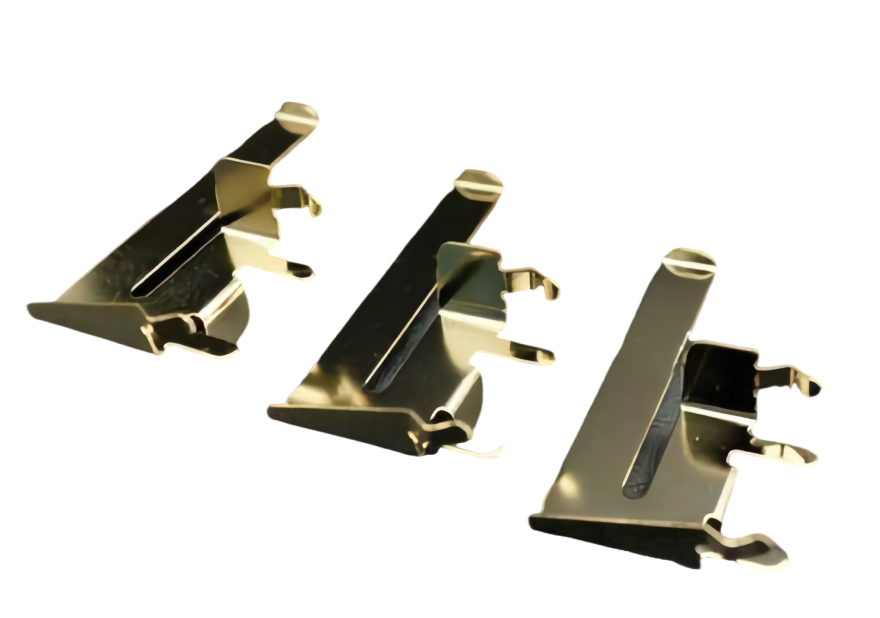

surface treatment cases