Introduction

In today’s competitive global market, sustainable manufacturing has moved from a buzzword to a strategic necessity. Companies across automotive, aerospace, medical devices, and consumer products are under pressure to reduce their carbon footprint, minimize waste, and adopt more circular economy practices.

One of the most impactful approaches is the recycling and re-use of materials, coupled with designing products and processes that support closed-loop manufacturing. By implementing these practices, manufacturers can achieve cost savings, resource efficiency, and compliance with global sustainability regulations.

What Is Sustainable Manufacturing?

Sustainable manufacturing refers to the creation of manufactured products through economically sound processes that:

- Minimize negative environmental impacts

- Conserve energy and natural resources

- Enhance employee and community safety

- Maintain economic competitiveness

It integrates lean manufacturing, energy efficiency, material recycling, and circular economy principles into one cohesive system.

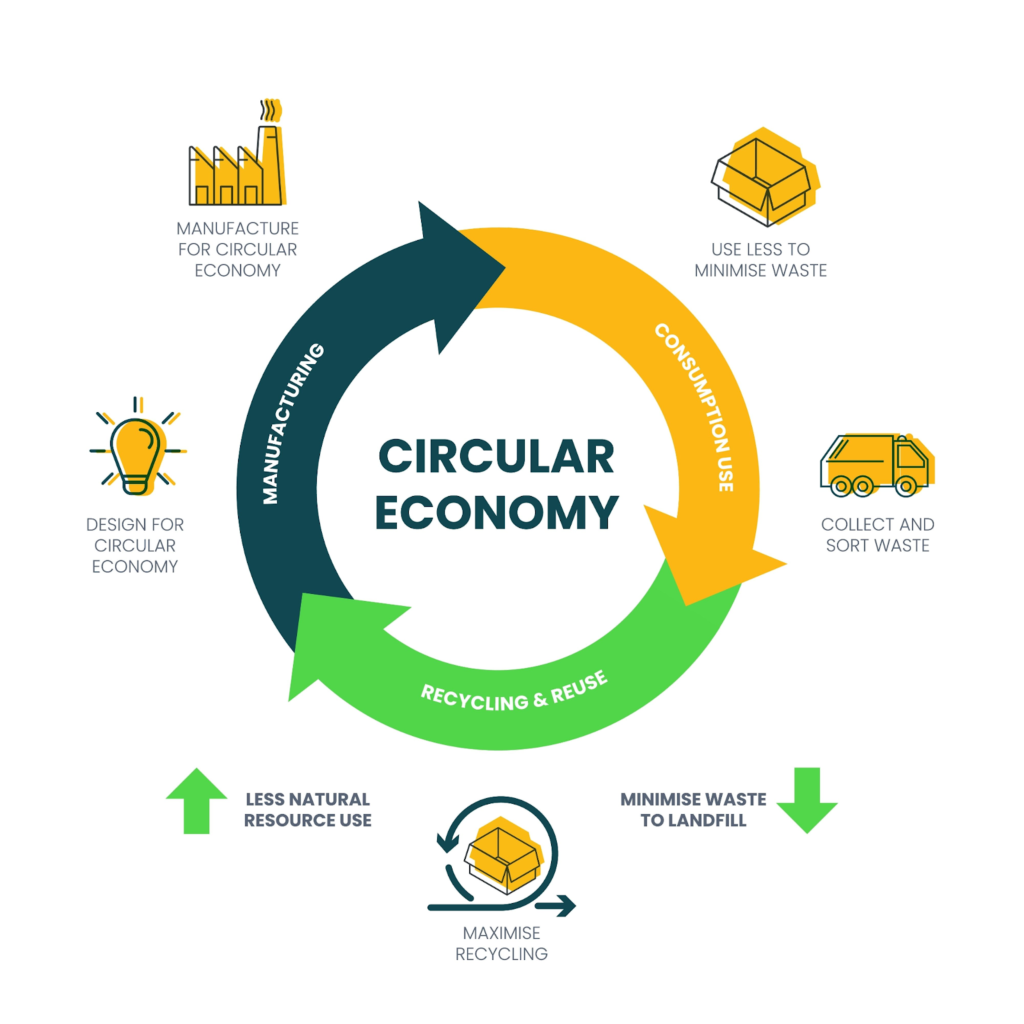

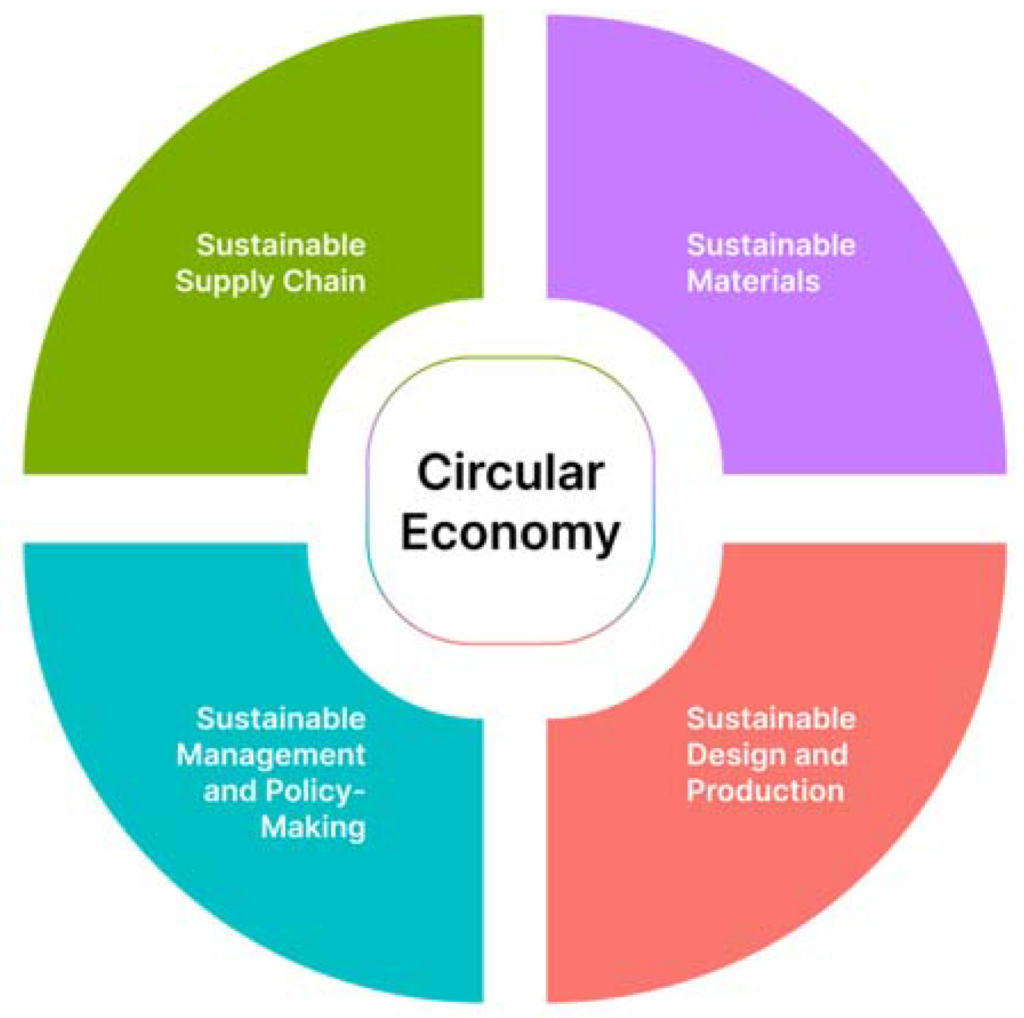

Circular Economy in Manufacturing

Unlike the traditional “take-make-dispose” linear economy, the circular economy seeks to close the loop by designing products and processes that keep materials in use for as long as possible.

Key principles include:

- Design for durability and recyclability

- Material recovery at end-of-life (EoL)

- Closed-loop supply chains that reintroduce recycled materials into production

- Sharing, remanufacturing, and repair strategies to extend product life

Benefits of Recycling in Sustainable Manufacturing

| Benefit | Example in Manufacturing | Impact on Business & Environment |

|---|---|---|

| Waste Reduction | Reusing scrap metals in CNC machining | Lowers disposal costs and reduces landfill usage |

| Cost Savings | Recycling plastics from injection molding sprues and runners | Decreases raw material purchases |

| Energy Efficiency | Producing aluminum from recycled material uses ~95% less energy than virgin | Significant energy and CO₂ savings |

| Supply Chain Resilience | Using recycled alloys to mitigate raw material shortages | Increases independence from volatile commodity markets |

| Brand & Compliance Advantage | Meeting EU Green Deal, ISO 14001, and customer sustainability demands | Enhances reputation and ensures regulatory compliance |

Real-World Applications

- Automotive Industry – Car manufacturers recycle aluminum, steel, and plastics to meet lightweighting and emission reduction goals.

- Aerospace – Composite materials are reclaimed and reprocessed for secondary applications, reducing costly waste.

- Electronics – Circular economy strategies recover rare earth elements from discarded circuit boards.

- Medical Devices – Hospitals and device manufacturers explore single-use device reprocessing, reducing waste streams.

Key Technologies Driving Sustainable Manufacturing

- Advanced Sorting and Separation – AI-powered systems identify and sort recyclable materials efficiently.

- Additive Manufacturing (3D Printing) – Reduces material waste by using only what is needed in a build.

- Closed-Loop Recycling Systems – Captures waste directly on the shop floor and reintegrates it into production.

- Blockchain for Traceability – Tracks recycled material use across the supply chain for transparency.

Challenges and Considerations

While sustainable manufacturing brings immense opportunities, manufacturers must address:

- Material Quality Degradation – Some recycled materials lose mechanical properties after multiple cycles.

- Infrastructure Gaps – Recycling facilities and logistics vary greatly across regions.

- Economic Trade-Offs – Initial investments in recycling systems may be high.

- Regulatory Compliance – Ensuring recycled materials meet standards (e.g., FDA for medical, FAA for aerospace).

Conclusion

Sustainable manufacturing, powered by circular economy models and material recycling, is redefining how industries design, produce, and manage products. Companies that embrace closed-loop supply chains not only reduce waste and energy consumption but also future-proof themselves against resource shortages, regulatory changes, and consumer expectations.

As manufacturing continues to evolve, the winners will be those who transform sustainability from a compliance exercise into a competitive advantage.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.