At Ze-tech Mold, Teflon® (PTFE) is our go-to engineering plastic for low-friction, chemically inert, and thermally stable components in medical, aerospace, semiconductor, and food processing industries. Discovered accidentally in 1938, this “wonder polymer” continues to revolutionize precision manufacturing. In this in-depth guide, we explore what Teflon is, its unique properties, grades, CNC machining tips, and high-performance applications.

What Is Teflon (PTFE)?

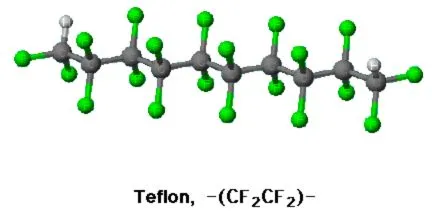

Teflon® is the DuPont brand name for Polytetrafluoroethylene (PTFE) — a synthetic fluoropolymer made by polymerizing tetrafluoroethylene (TFE) gas.

Chemical Formula: (C₂F₄)ₙ

Nicknamed: “The Slipperiest Substance on Earth”

Unlike typical plastics, PTFE has no melting point — it transitions from solid to gel at 327°C (620°F).

Remarkable Properties of PTFE

| Property | Value / Advantage |

|---|---|

| Coefficient of Friction | 0.05–0.10 (lowest of any solid) |

| Chemical Resistance | Inert to all solvents, acids, bases (except molten alkali metals) |

| Temperature Range | -200°C to +260°C (-328°F to +500°F) |

| Dielectric Strength | 60–170 kV/mm → ideal insulator |

| Non-Stick Surface | Nothing adheres (even super glue releases) |

| FDA & USP Class VI Approved | Safe for food & medical contact |

| UV & Weather Resistance | Zero degradation outdoors |

Teflon Grades & Fillers

| Grade | Composition | Best For |

|---|---|---|

| Virgin PTFE | 100% pure PTFE | Food, medical, electrical |

| Glass-Filled (15–25%) | PTFE + glass fibers | Wear resistance, creep reduction |

| Carbon-Filled (25%) | PTFE + carbon/graphite | High load, anti-static |

| Bronze-Filled (40–60%) | PTFE + bronze powder | Heavy-duty bearings, high pressure |

| PEEK-Filled | PTFE + PEEK | High-temp, high-strength seals |

CNC Machining Teflon: Expert Techniques

PTFE is notorious for machining challenges — but we’ve mastered it:

| Challenge | Ze-tech Mold Solution |

|---|---|

| Soft & gummy | Sharp polished carbide, no coatings |

| Thermal expansion (2x steel) | Climb milling, light cuts (0.1–0.3 mm) |

| Chip wrapping | High-volume air blast, no coolant |

| Dimensional creep | Stress-relieve blanks at 120°C pre-machining |

| Burr formation | Zero rake angle tools, final pass at 0.05 mm |

Our Parameters (Virgin PTFE):

- Turning: 300–500 m/min, 0.1 mm/rev

- Milling: 400 m/min, Ap 0.5 mm, Ae 50%

- Tolerance: ±0.02 mm achievable

High-Performance Applications

| Industry | Teflon Components |

|---|---|

| Medical | Catheter linings, syringe plungers, surgical guides |

| Aerospace | Cryogenic seals, wire insulation, thrust washers |

| Semiconductor | Wafer handling tools, O-rings, valve seats |

| Food Processing | Conveyor bearings, mixer seals, non-stick molds |

| Automotive | Transmission thrust washers, fuel line insulators |

Teflon vs. Other Engineering Plastics

| Material | Friction | Temp (°C) | Chemical Resistance | Cost |

|---|---|---|---|---|

| PTFE | ★★★★★ | -200 to +260 | ★★★★★ | $$ $ |

| PEEK | ★★★★ | -60 to +250 | ★★★★ | $$$$ $ |

| Nylon | ★★★ | -40 to +120 | ★★ | $ |

| UHMWPE | ★★★★ | -200 to +80 | ★★★ | $$ |

Why Choose Ze-tech Mold for Teflon Parts?

- Dedicated PTFE CNC Stations (cleanroom-ready)

- Full Material Traceability (DuPont, Chemours, Daikin)

- In-House Annealing Ovens → zero post-machining distortion

- Surface Treatments: Etching for bonding, laser marking

- 10,000+ Projects | 98% On-Time Delivery

Ready to Harness the Power of Teflon?

From life-critical medical seals to space-grade insulators, Teflon delivers unmatched reliability. Let Ze-tech Mold precision-machine your PTFE components — with zero stick, zero failure.

📞 Contact Michelle Tang: 0086 18025337983