Introduction

In modern manufacturing, speed, flexibility, and cost efficiency are critical for meeting market demands. For prototypes, pre-series runs, or niche products, traditional injection molding may be too costly and time-consuming due to expensive tooling and long setup times. This is where silicone vacuum casting becomes a valuable solution.

Silicone vacuum casting enables manufacturers to produce high-quality plastic or elastomer components in low volumes—bridging the gap between prototyping and full-scale production. This process delivers precision, repeatability, and functional parts without the high capital investment required for hard tooling.

What is Silicone Vacuum Casting?

Silicone vacuum casting (also called urethane casting) is a process in which a silicone mold, created from a master pattern, is used to replicate parts under vacuum conditions. Typically, polyurethane resins are poured into the mold to produce detailed replicas.

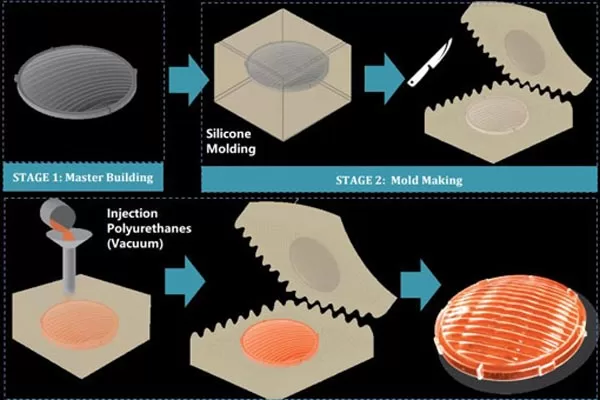

Key steps include:

- Master Model Creation – Often CNC machined or 3D printed.

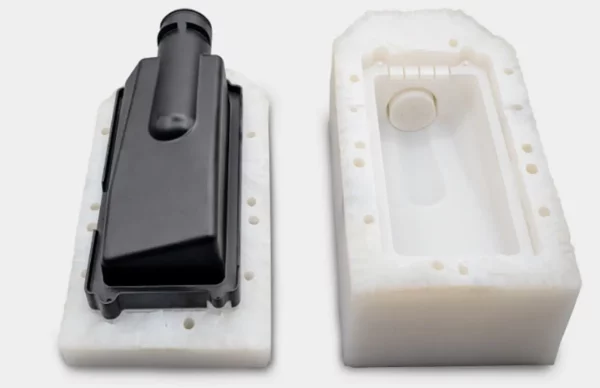

- Silicone Mold Making – The master is encapsulated in silicone to form the mold.

- Vacuum Casting Process – Resin is poured into the mold under vacuum to avoid bubbles and ensure detail accuracy.

- Curing and Finishing – The parts are cured, demolded, and finished as required.

Advantages of Silicone Vacuum Casting in Low-Volume Production

- Cost-effective – Lower mold-making cost compared to steel/aluminum tooling.

- Speed – Mold preparation and casting can be completed in days, not weeks.

- Material Versatility – Wide choice of polyurethane resins mimicking ABS, PP, or even elastomers.

- High-Quality Finish – Excellent surface finish, often suitable for end-use parts.

- Design Flexibility – Supports undercuts, complex geometries, and transparent or colored materials.

Comparison: Silicone Vacuum Casting vs. Injection Molding

| Criteria | Silicone Vacuum Casting | Injection Molding |

|---|---|---|

| Setup Cost | Low – silicone molds are inexpensive | High – requires costly steel/aluminum tooling |

| Lead Time | Short (days to 1–2 weeks) | Long (4–8 weeks or more) |

| Volume Suitability | Low to medium (10–100 parts) | High (thousands to millions of parts) |

| Material Options | Polyurethane resins (ABS-like, PP-like, elastomer-like, transparent) | Engineering thermoplastics, high-performance resins |

| Surface Quality | Excellent, smooth, near-injection quality | Excellent, highly consistent |

| Durability of Mold | Limited (typically 20–25 shots per mold) | Long-lasting (up to hundreds of thousands) |

Applications of Silicone Vacuum Casting

- Prototype Validation – Producing realistic prototypes with end-use properties.

- Pre-Series Runs – Testing products before committing to mass production.

- Consumer Products – Low-volume production of customized goods.

- Medical Devices – Functional models and small batches of housings.

- Automotive & Aerospace – Interior components, small functional parts, and design validation.

Conclusion

Silicone vacuum casting is an ideal solution for low-volume production where speed, flexibility, and cost are priorities. It bridges the gap between rapid prototyping and injection molding, enabling companies to bring products to market faster while minimizing investment risk.

For manufacturers navigating today’s competitive environment, integrating silicone vacuum casting into the product development cycle offers both technical and economic advantages.

What We Offer at Ze-tech Mold

At Ze-tech Mold, we provide end-to-end manufacturing services, including:

- CNC Machining & Turning

- 3D printing prototype

- sheet metal fabrication

- silicone vacuum casting

- Rapid Injection molding

- surface treatments

- PCB & PCBA

Whether you’re looking for precision CNC parts or custom prototypes, we provide tailored solutions for both low-volume and large-scale production. Get in touch with us today to discuss your project and see how we can bring your ideas to life.