At Ze-tech Mold, titanium is one of our most in-demand materials for medical, aerospace, automotive, and robotic components. Known as the “space-age metal,” titanium combines extreme strength, featherweight density, and unmatched corrosion resistance. In this ultimate guide, we explore what titanium is, its unique properties, geological origins, commercial grades, and precision applications — all backed by our 15+ years of ISO 9001:2015-certified CNC machining expertise.

What Is Titanium?

Titanium (Ti) is a lustrous transition metal (atomic number 22) discovered in 1791 by William Gregor and named after the Titans of Greek mythology. It’s the 9th most abundant element in Earth’s crust and the 4th most abundant structural metal after aluminum, iron, and magnesium.

Key Fact: Pure titanium is as strong as steel but 45% lighter, and twice as strong as aluminum but only 60% heavier.

Core Material Properties of Titanium

| Property | Value / Advantage |

|---|---|

| Density | 4.51 g/cm³ (60% of steel) |

| Tensile Strength | 240–1,400 MPa (grade-dependent) |

| Corrosion Resistance | Forms self-healing TiO₂ passivation layer |

| Biocompatibility | No allergic reactions; osseointegration |

| Thermal Conductivity | Low (21.9 W/m·K) → excellent heat insulation |

| Operating Temperature | Up to 600°C (1,100°F) without creep |

| Modulus of Elasticity | ~110 GPa (half of steel → spring-like) |

Geological Origins & Extraction

Titanium never occurs pure in nature. It’s extracted from minerals:

| Mineral | Location | % of Global Supply |

|---|---|---|

| Ilmenite (FeTiO₃) | Australia, South Africa, China | ~90% |

| Rutile (TiO₂) | Sierra Leone, India | ~8% |

Extraction Process (Kroll Process):

- TiO₂ → TiCl₄ (chlorination)

- TiCl₄ + Mg → Ti sponge + MgCl₂

- Vacuum arc remelting (VAR) → ingots

Commercial Titanium Grades

| Grade | Type | Composition | Best For |

|---|---|---|---|

| Grade 1–4 | Commercially Pure (CP) | 99.5%+ Ti | Chemical tanks, marine |

| Grade 5 (Ti-6Al-4V) | Alpha-Beta Alloy | 6% Al, 4% V | Aerospace, medical, automotive |

| Grade 9 (Ti-3Al-2.5V) | Near-Alpha | 3% Al, 2.5% V | Hydraulic tubing, sports |

| Grade 23 (Ti-6Al-4V ELI) | Extra Low Interstitial | Medical-grade Grade 5 | Implants, surgical tools |

Machining Titanium: Challenges & Ze-tech Mold Solutions

| Challenge | Solution |

|---|---|

| Low thermal conductivity → heat buildup | High-pressure coolant (70 bar), MQL |

| Work hardening | Sharp PCD tools, low cutting speed (40–80 m/min) |

| Galling & chip welding | TiAlN-coated carbide, peck drilling |

| High cost | Near-net-shape forgings + CNC finish |

Our Parameters (Grade 5):

- Face Milling: 60 m/min, 0.1 mm/rev, Ap 1.0 mm

- Turning: 80 m/min, 0.15 mm/rev

- Surface Finish: Ra 0.4 μm achievable

High-Performance Applications

| Industry | Titanium Parts |

|---|---|

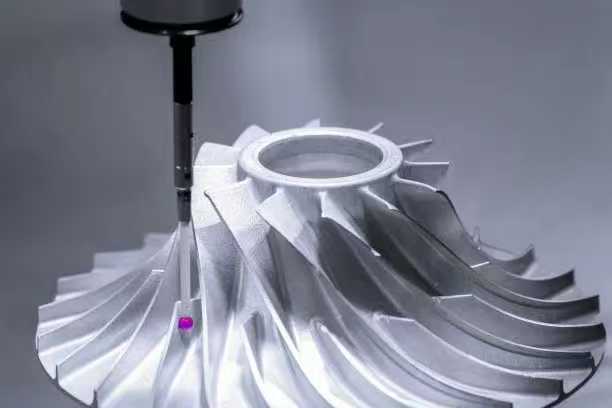

| Aerospace | Turbine blades, landing gear, fuselage frames |

| Medical | Hip/knee implants, bone plates, dental screws |

| Automotive | Connecting rods, valves, exhaust systems (supercars) |

| Robotics | Lightweight grippers, drone arms |

| Marine | Propeller shafts, subsea connectors |

Why Choose Ze-tech Mold for Titanium Parts?

- 50+ CNC Machines (including 5-axis DMG MORI)

- In-House Metrology: CMM, X-ray fluorescence, roughness tester

- Biocompatibility Certification (ISO 13485 ready)

- Free DFM + Material Traceability

- 10,000+ Projects | 98% On-Time Delivery

Ready to Engineer with Titanium?

From life-saving implants to record-breaking race cars, titanium delivers uncompromising performance. Let Ze-tech Mold turn your titanium design into reality — with precision, speed, and full traceability.

📞 Contact Michelle Tang: 0086 18025337983