Introduction

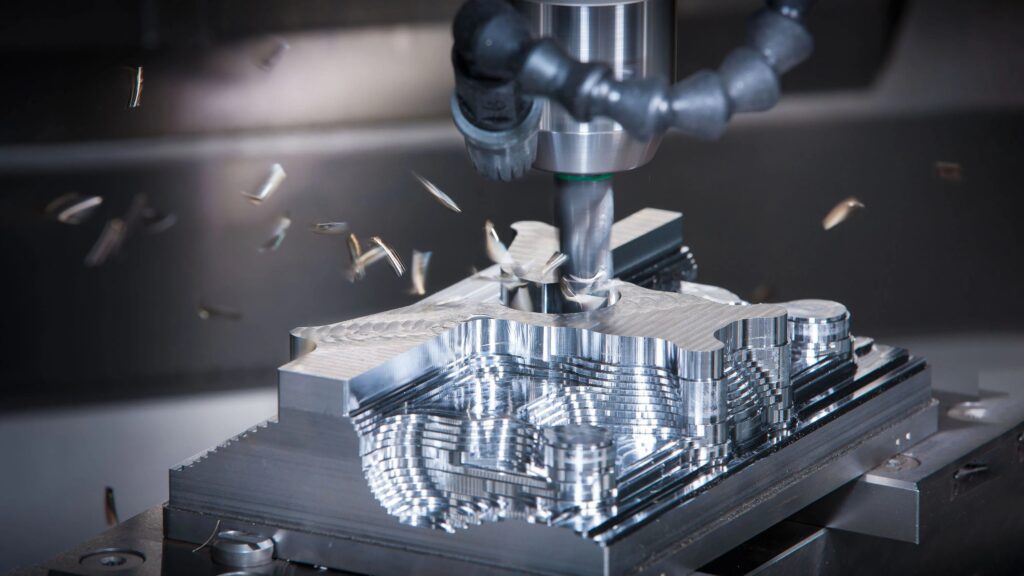

In modern CNC machining, the cutting tool is at the heart of precision manufacturing. Whether producing aerospace components, automotive parts, or consumer electronics, tool wear directly impacts dimensional accuracy, surface finish, production efficiency, and overall costs.

While tool wear is inevitable, understanding the mechanisms behind it and applying effective maintenance strategies can significantly extend tool life and ensure consistent part quality. This article explores the types of tool wear, contributing factors, detection methods, and best maintenance practices that manufacturers should adopt.

Types of Tool Wear in CNC Machining

Tool wear can take different forms depending on the cutting conditions, workpiece material, and tool composition:

| Type of Wear | Cause | Visual Indicator | Impact on Machining |

|---|---|---|---|

| Flank Wear | Continuous rubbing against workpiece surface | Polished band along tool flank | Gradual loss of dimensional accuracy |

| Crater Wear | High cutting temperature + chip friction | Pit formation on tool rake face | Poor surface finish, potential tool breakage |

| Notch Wear | Stress concentration at workpiece edges | Localized chipping or grooves | Reduced cutting edge strength |

| Built-Up Edge (BUE) | Adhesion of workpiece material | Deposits on tool cutting edge | Rough surface, unpredictable tool behavior |

| Thermal Cracking | Rapid heating/cooling cycles | Visible cracks along cutting edge | Sudden catastrophic tool failure |

Factors Contributing to Tool Wear

- Cutting Parameters

- High cutting speeds generate excessive heat → accelerate flank and crater wear.

- Aggressive feed rates increase mechanical stress → faster edge chipping.

- Workpiece Material

- Hard alloys (e.g., Inconel, titanium) and abrasive composites cause rapid tool erosion.

- Soft, sticky metals (e.g., aluminum) increase the risk of built-up edge.

- Tool Material and Coating

- Carbide tools withstand heat better than HSS.

- PVD coatings (TiAlN, DLC) reduce friction and extend tool life.

- Coolant and Lubrication

- Proper coolant application reduces heat and chip adhesion.

- Mist or MQL (Minimum Quantity Lubrication) can be effective for eco-friendly operations.

- Machine Condition

- Poor spindle alignment or vibration accelerates wear unevenly.

Detecting Tool Wear: From Manual Checks to Smart Monitoring

| Method | Description | Advantage |

|---|---|---|

| Visual Inspection | Checking for chips, cracks, discoloration | Simple, but subjective |

| Tool Life Tracking | Counting cycles/hours of use | Prevents overuse |

| Acoustic Emission Monitoring | Detects high-frequency sound from tool wear | Early detection of cracks |

| Vibration Analysis | Monitors changes in spindle vibration | Identifies imbalance or wear |

| AI-based Predictive Maintenance | Uses sensors + machine learning to predict tool failure | Maximizes uptime, reduces cost |

👉 Many smart factories now adopt Industry 4.0 predictive maintenance, integrating IoT sensors into CNC machines for real-time wear detection.

Best Practices for Tool Maintenance

- Optimize Cutting Conditions – Balance speed and feed for productivity without overloading the tool.

- Apply Proper Coolant Strategy – Use flood, mist, or cryogenic cooling depending on material.

- Schedule Preventive Tool Changes – Replace tools before they reach failure threshold.

- Use Regrinding and Recoating Services – Extend tool lifespan by reshaping cutting edges.

- Adopt Digital Tool Management – Implement ERP/MES systems to track tool usage and predict replacement.

Benefits of Effective Tool Maintenance

| Benefit | Impact |

|---|---|

| Extended Tool Life | 20–40% longer lifespan, reducing tooling costs |

| Consistent Product Quality | Maintains tight tolerances and smooth surface finishes |

| Higher Productivity | Less downtime, improved cycle times |

| Lower Scrap Rate | Reduces defective parts caused by dull tools |

| Operator Safety | Prevents accidents from sudden tool breakage |

📊 According to a 2023 industry survey, companies using predictive tool maintenance reduced unplanned downtime by up to 25%.

Real-World Example

In aerospace component manufacturing, a CNC shop reported saving $150,000 annually after switching from manual inspections to predictive tool monitoring. By replacing tools based on wear data instead of fixed schedules, they extended tool life by 30% while avoiding sudden failures during titanium machining.

Conclusion

Tool wear is one of the most critical challenges in CNC machining, but it can be controlled with the right combination of optimized parameters, smart monitoring, and preventive maintenance. Manufacturers who invest in tool care not only lower costs but also gain a competitive advantage in producing high-quality, precision-engineered components.

👉 At Ze-tech Mold, we combine advanced CNC machining with strict tool management systems, ensuring precision, efficiency, and long-term reliability.

📩 Contact us today to discuss your CNC project and discover how our machining expertise can support your business.