Introduction

In product development, choosing the right prototyping and production method can directly impact cost, lead time, and product performance. Two commonly compared techniques are silicone vacuum casting and rapid injection molding. While both are widely used for producing prototypes and low-volume runs, they serve different purposes. Understanding when to switch from vacuum casting to rapid injection molding is critical for scaling production efficiently.

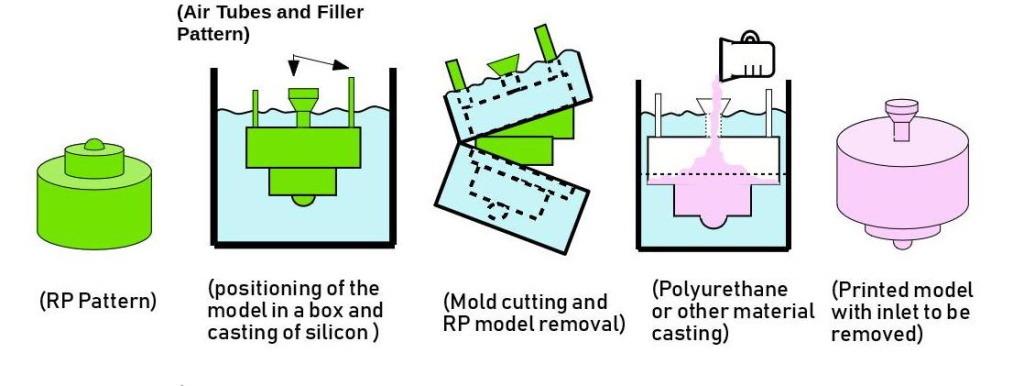

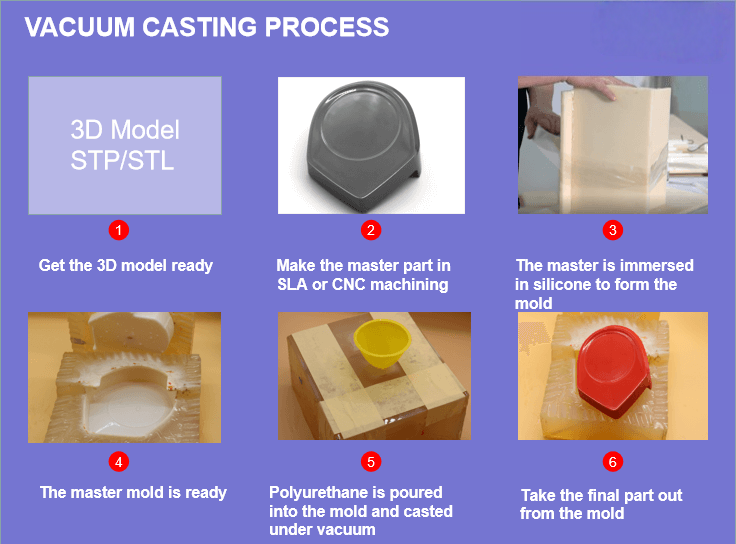

What Is Silicone Vacuum Casting?

Silicone vacuum casting (also known as polyurethane casting) uses a silicone mold to replicate parts from a master prototype, typically produced by 3D printing or CNC machining. This method is often chosen for:

- Low-volume runs: 10–50 pieces per mold.

- Material simulation: Offers flexibility to mimic ABS, PP, or elastomers.

- Fast turnaround: Average lead time of 7–10 days.

- Surface quality: Excellent for achieving smooth, near-production finishes.

📊 Industry Data: According to Wohlers Report 2023, vacuum casting remains one of the top choices for pre-series testing, especially when functional prototypes are needed in less than 2 weeks.

What Is Rapid Injection Molding?

Rapid injection molding uses aluminum or soft steel molds to produce plastic parts with the same material and processes used in mass production. Unlike vacuum casting, it prepares products for true manufacturing conditions. Key features include:

- Higher volumes: 100 to 100,000+ parts possible.

- Production-grade materials: Wide range of thermoplastics, elastomers, and filled materials.

- Consistency: High dimensional accuracy and repeatability.

- Lead time: As fast as 10–15 business days for tooling and first parts.

📊 Data Point: Industry benchmarks show that rapid injection molding can cut time-to-market by 30–50% compared to conventional steel tooling.

Comparing Silicone Vacuum Casting vs. Rapid Injection Molding

| Factor | Silicone Vacuum Casting | Rapid Injection Molding |

|---|---|---|

| Best Use Case | Prototyping, design validation, marketing samples | Pre-production, pilot runs, mass production |

| Volume | 10–50 units per mold | 100–100,000+ parts |

| Material Options | PU resins simulating ABS, PP, rubber | Production-grade thermoplastics & composites |

| Lead Time | 7–10 days | 10–15 days (tooling + first shot) |

| Cost | Lower upfront cost, higher per-part cost | Higher upfront cost, lower per-part cost |

| Durability | Silicone mold lasts ~20 uses | Aluminum/steel molds last thousands of cycles |

When to Choose Rapid Injection Molding Over Silicone Vacuum Casting

- Scaling Beyond Prototype Volumes

If your product moves from tens to thousands of units, rapid injection molding becomes more cost-effective due to its lower per-part cost. - Need for Production-Grade Materials

Vacuum casting resins mimic materials, but they don’t fully replicate the performance of actual thermoplastics. For applications requiring impact resistance, flame retardancy, or FDA compliance, injection molding is the right choice. - Regulatory or Functional Testing

For industries like automotive, aerospace, or medical devices, testing under real production conditions is mandatory. Rapid injection molding ensures compliance. - Faster Transition to Mass Production

Prototyping with rapid injection molding shortens the bridge to full-scale manufacturing, avoiding discrepancies between test and production parts.

📊 Case Example: A consumer electronics company reduced their time-to-market by 6 weeks by switching from vacuum casting to rapid injection molding once they reached the 1,000-unit stage.

Conclusion

Silicone vacuum casting remains a powerful tool for early-stage prototypes and low-volume production, but once your product requires higher volume, regulatory testing, or production-grade materials, rapid injection molding is the natural next step.

At Ze-Tech Mold, we specialize in both silicone vacuum casting and rapid injection molding, ensuring a smooth transition from prototype to mass production. Whether you need 10 pieces or 100,000 parts, our engineering team will provide the best solution tailored to your project.

👉 Contact us today to discuss how we can accelerate your product development with the right manufacturing strategy.