In today’s fast-paced product development environment, companies are constantly searching for reliable ways to turn designs into functional prototypes — quickly and accurately. While technologies like 3D printing have grown in popularity, CNC machining remains the most dependable and scalable solution for both prototyping and small-batch production.

🔧 What Is CNC Machining?

CNC (Computer Numerical Control) machining is a subtractive manufacturing process where pre-programmed software controls the movement of tools and machinery. It’s known for producing highly accurate, repeatable parts out of metals and plastics, and is widely used across industries such as:

- Medical devices

- Consumer electronics

- Robotics

- Automotive and aerospace

⚙️ Why CNC Machining Still Leads the Way

1. Exceptional Precision

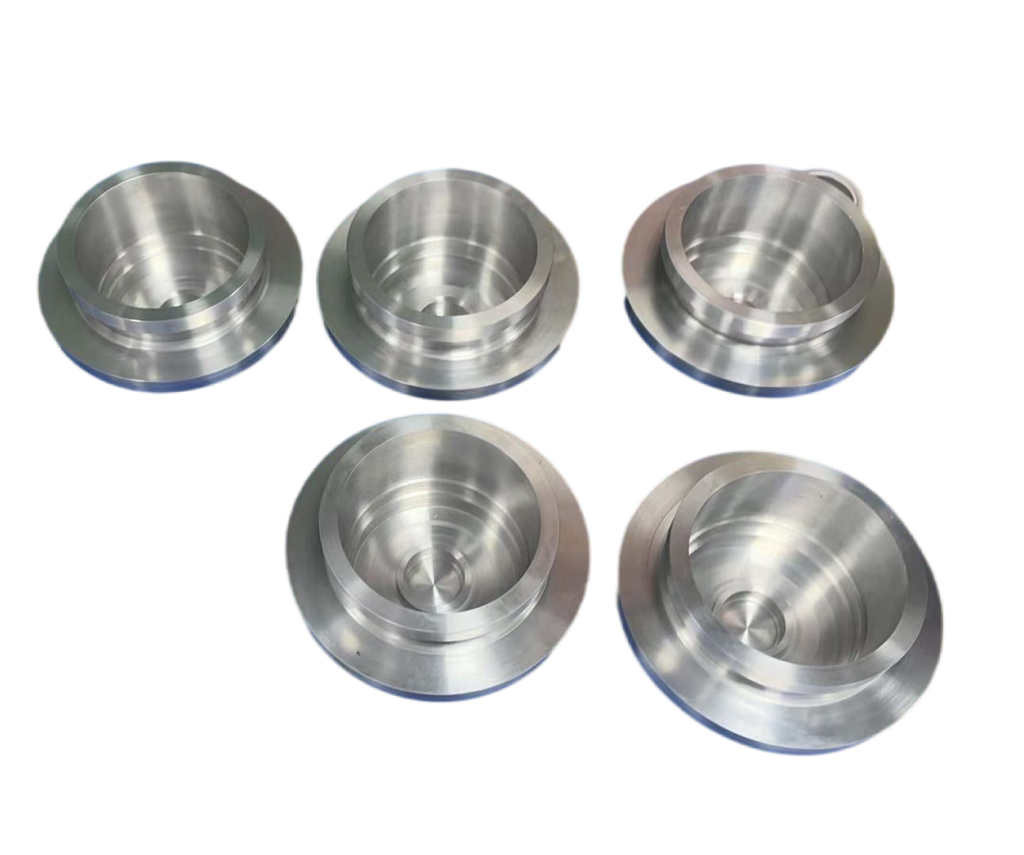

CNC machining achieves tight tolerances, often as precise as ±0.01mm. This is critical for components that require high structural integrity and fitment — such as connectors, brackets, enclosures, and gears.

2. Wide Material Selection

CNC supports a broad range of materials including aluminum, stainless steel, brass, POM, and ABS — giving engineers flexibility during design and testing.

3. Ideal for Functional Prototypes

Unlike 3D printed parts, CNC-machined components can be tested under real-world conditions: heat, stress, wear, and assembly. It’s perfect for validating mechanical performance before mass production.

4. Scalable to Small-Batch Production

Once a design is finalized, CNC is ready to scale — no need for mold investment or reprogramming. It bridges the gap between one-off prototypes and full production.

5. Fast Turnaround

At ZE-TECH MOLD, we deliver CNC parts within 5–7 working days from quote to shipment. We understand that speed is critical to your development timeline.

🔩 What ZE-TECH MOLD Offers

As a trusted manufacturing partner, ZE-TECH MOLD helps hardware startups, design firms, and sourcing managers bring their products to life with:

- Custom CNC Machining & Turning

- Surface Finishing (Anodizing, Powder Coating, Polishing)

- Sheet Metal Fabrication

- 3D Printing (SLA, SLS, FDM)

- Injection Molding

- PCB & PCBA (upon request)

We offer fast quotes, DFM feedback, flexible MOQs, and global shipping.

💡 Ready to Get Started?

Whether you’re working on a next-gen wearable, a robotics solution, or a medical prototype — our team is ready to support you with quality and speed.

📩 Send us your 3D drawing today and get a quote within 24 hours.

📧 Email: info@zetechmold.com